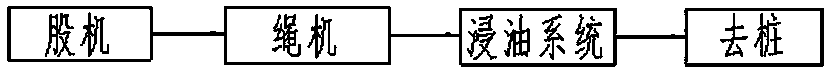

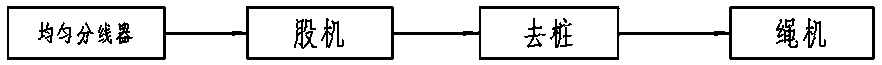

Method for producing oily fiber rope from oil-immersed fiber wires through uniform distributor

A technology of fiber rope and fiber thread, which is applied in auxiliary devices for rope making, textiles and papermaking, textile cables, etc. It can solve the problems of uneven oil content inside and outside, unstable oil content of rope, large change of rope diameter, etc., and achieve high oil content. Uniformity and stability, uniform grease, and quality-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

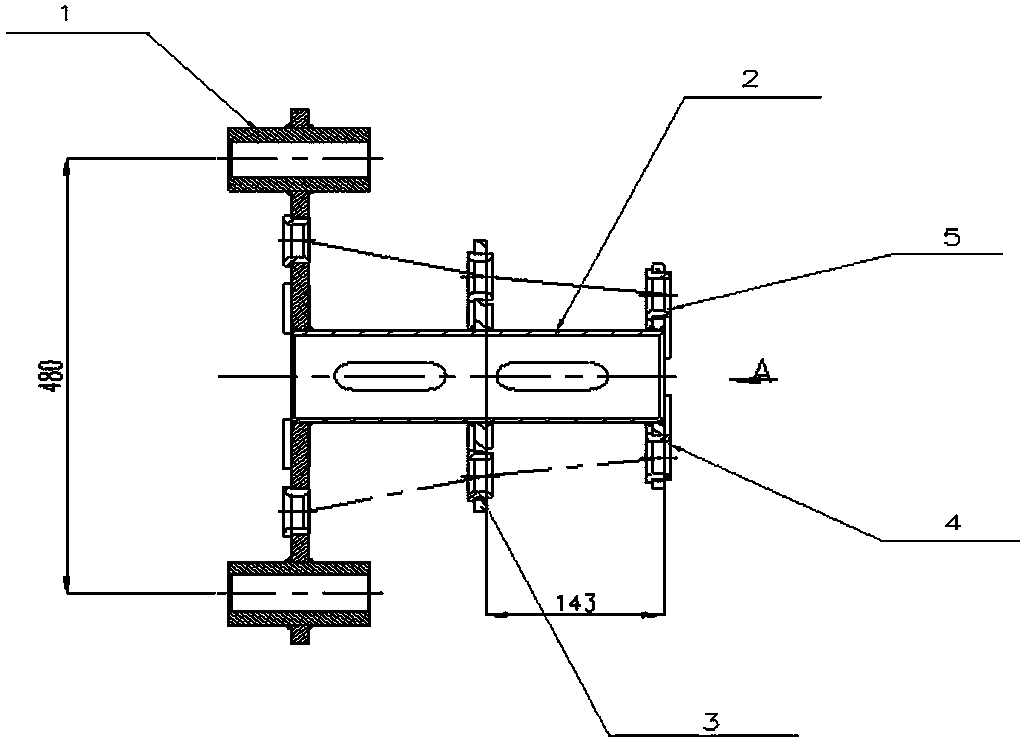

[0013] The method for producing oil-containing fiber ropes from the oil-soaked fiber thread through the uniform thread divider according to the present invention, the specific implementation mode, firstly, a set of uniform thread divider is set, and the composition of the uniform thread divider mainly includes: the line inlet line divider 1 , Connecting pipe 2, Middle distribution board 3, Rear distribution board 4, Mold cover 5. Seven mold sets 5 are evenly distributed on each line distribution plate, and the mold sets 5 are welded and fixed on each line line plate, and each line line plate is respectively symmetrically welded and fixed on the connecting pipe 2 .

[0014] Each distribution board is symmetrical to the connecting pipe 2, and the axial distance from the incoming wire distribution board 1, the middle distribution board 3, the rear distribution board 4 to the connecting pipe 2 decreases in turn.

[0015] The distance between the two incoming line distribution boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com