Method and device for reducing cashmere balling broken ends

A ball-forming and cashmere technology, which is applied in the processing of textile materials, textile and paper making, and liquid/gas/vapor removal, etc., can solve the problems of many broken ends of cashmere strips, affecting the quality of the balls, and the strength of cashmere strips being greatly reduced. Achieve the effect of avoiding physical and chemical changes, flexible use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

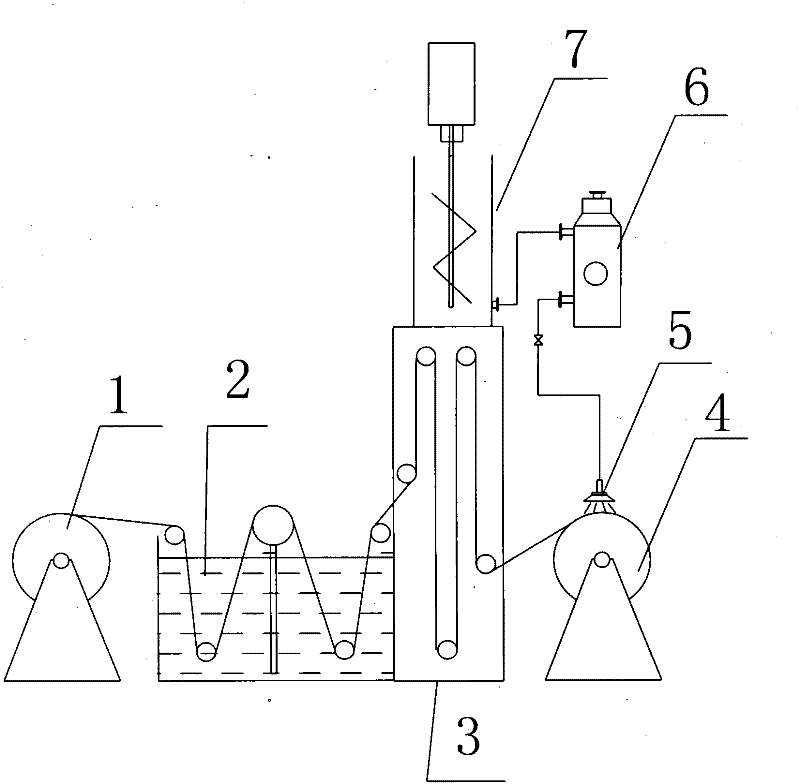

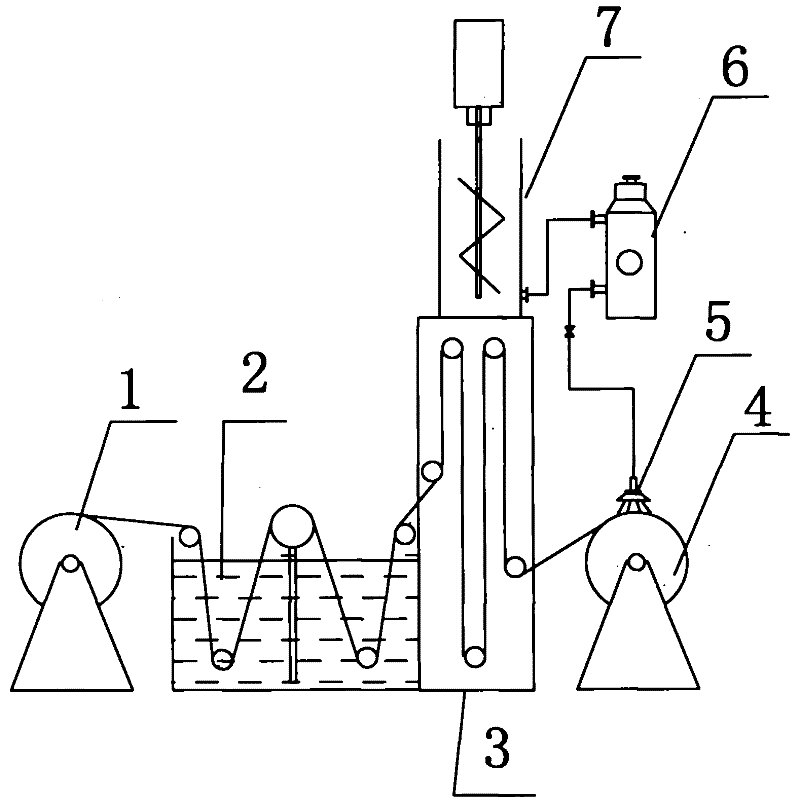

Image

Examples

Embodiment

[0025] The specific processing steps are as follows: After the cashmere strips are washed in the water tank, they enter the drying room for drying. The dried cashmere strips are directly wound on the ball forming roller. The spray liquid of the agent is evenly sprayed on the cashmere strip through the nozzle during the winding process of the cashmere strip to the drum, and the cashmere strip is fully rolled on the drum and becomes a semi-finished product for storage;

[0026] The drying temperature in the drying room is controlled at 85-90°C, and the drying time is about 3-4 minutes;

[0027] The spray liquid is composed of: antistatic agent (s-10), softener (zk-38) and water, and the ingredient ratio = 10:1:50. The preparation step is to add the antistatic agent and softener to the water in proportion and stir evenly can;

[0028] Spray atomization degree: The atomization flow rate is kept at 1-2 liters per minute or when the cashmere strip is wound on the drum without liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com