Pneumatic tire tread pattern structure for two-wheeled vehicle

A technology for pneumatic tires and tread patterns, applied in the field of tire tread patterns, can solve the problems of affecting safety, insufficient grip, and low edge components of grooves, etc., to ensure tire drainage performance, increase edge components, and improve drainage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

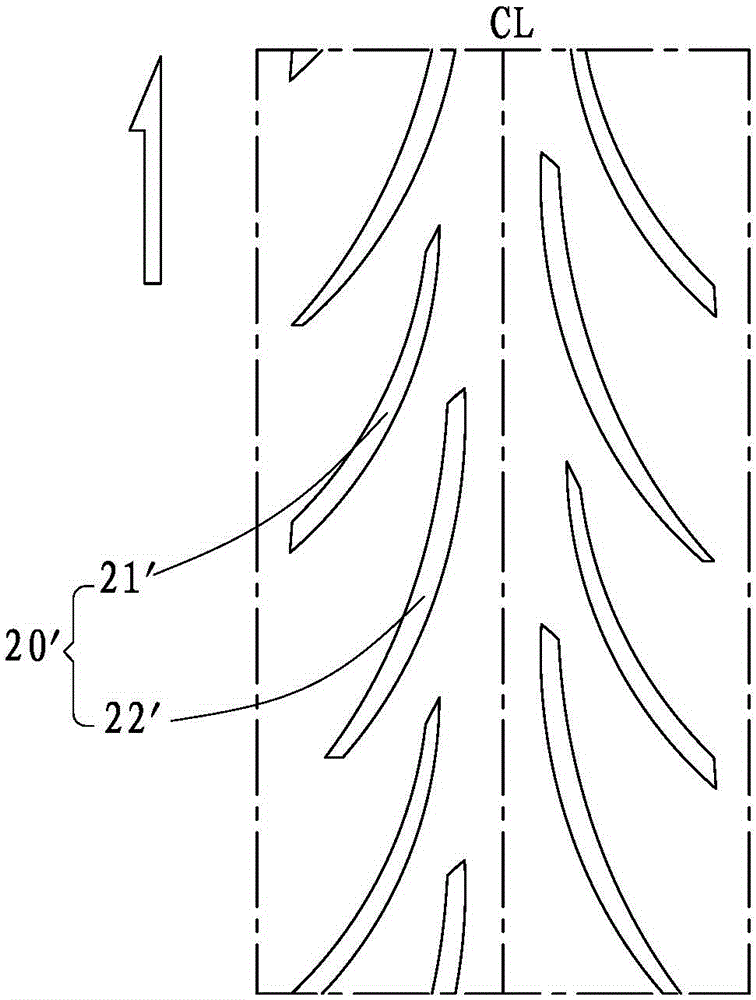

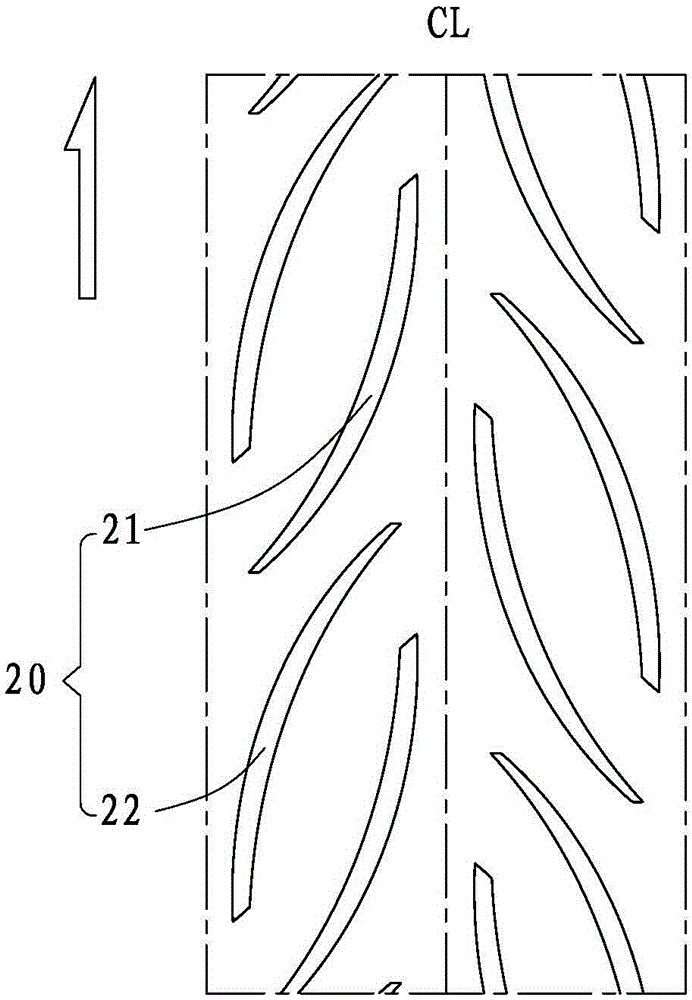

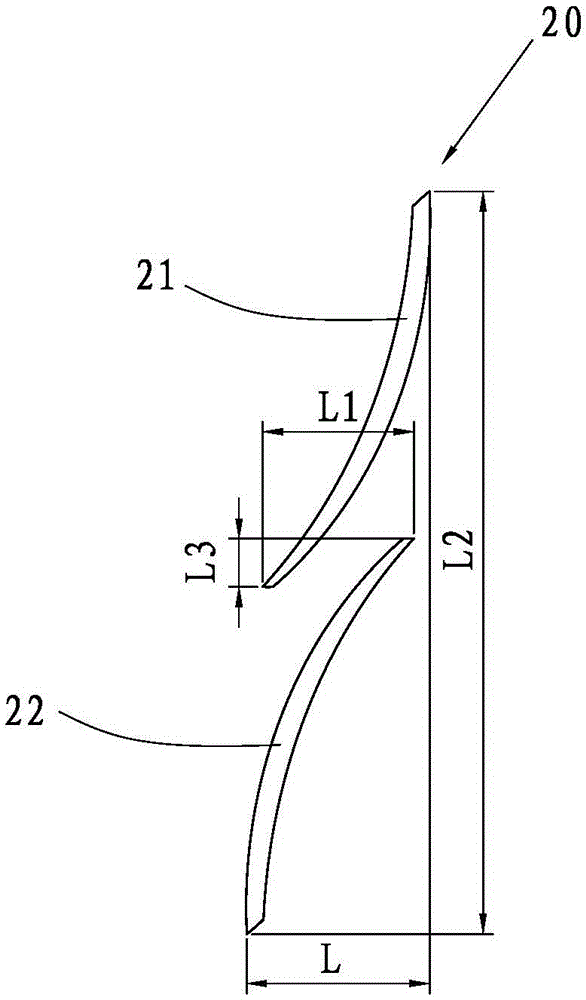

[0023] Such as figure 2 , image 3 As shown, the present invention discloses a tread pattern structure of a pneumatic tire for two-wheeled vehicles. The tire tread is composed of several oblique pattern main groove groups 20 that are symmetrical to the tread centerline CL and arranged in a staggered manner. The main groove group 20 is composed of a first inclined pattern main groove 21 and a second inclined pattern main groove 22 extending obliquely from the center of the tread to the shoulder in an arc shape, and the first inclined pattern main groove 21 and the second inclined pattern main groove The arc shape of 22 is set forward and reverse; the first inclined pattern main groove 21 close to the center of the tread is in a concave arc shape, so as to be in the same direction as the rotation direction; the second inclined pattern main groove 22 away from the tread center is convex The arc shape is opposite to the direction of rotation; the first oblique pattern main groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com