An equilateral triangle carbon fiber telescopic rod

A technology of equilateral triangles and telescopic rods, which is applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of inconsistent radial relative angle positions, weakening application effects, and restricting applications, so as to achieve relatively stable and consistent expansion and contraction The effect of good resistance and uniform resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

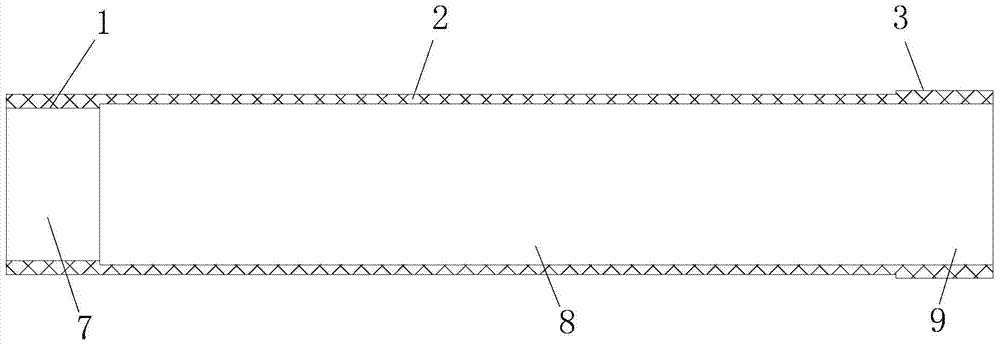

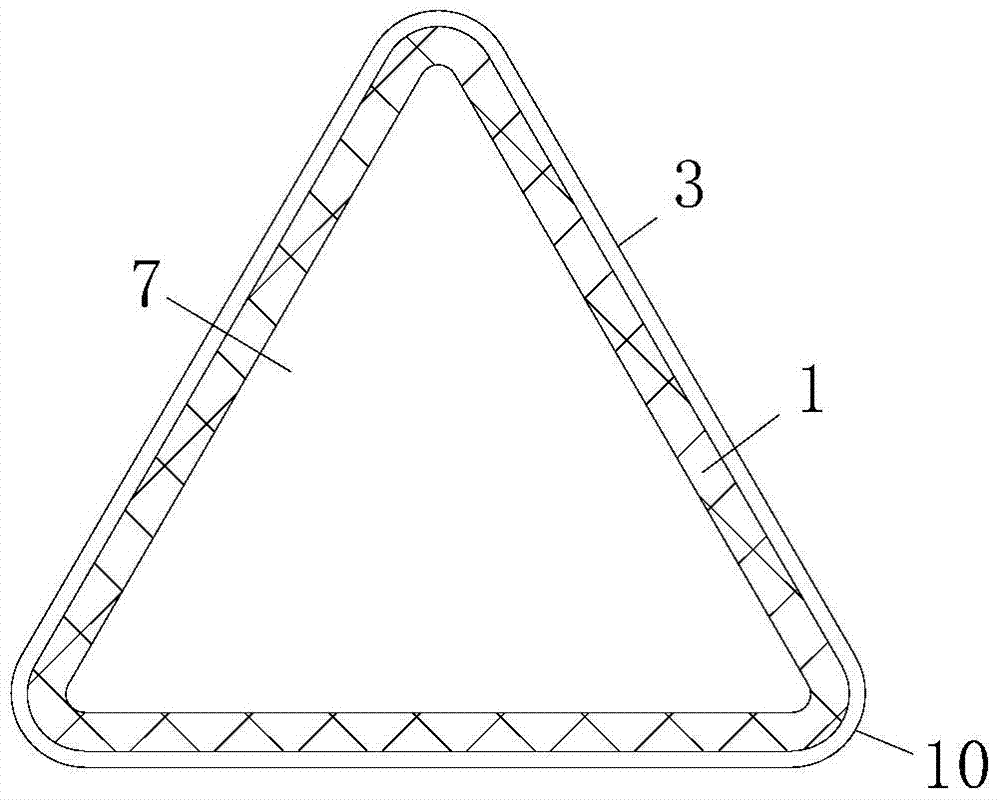

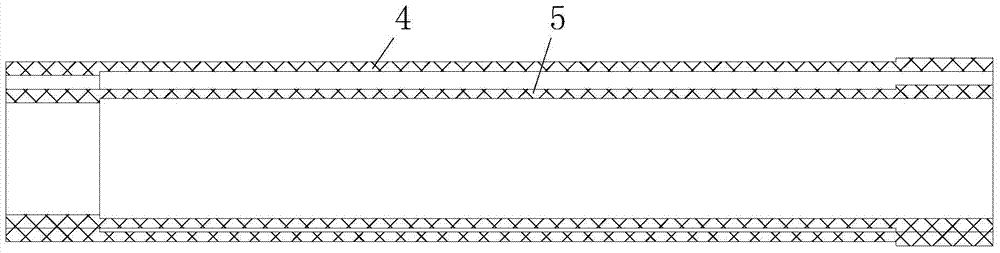

[0014] In this embodiment, refer to figure 1 , figure 2 , image 3 and Figure 4 , the equilateral triangular carbon fiber telescopic rod, which is made of carbon fiber, is composed of a number of telescopic single tubes nested in sequence from the outside to the inside, and each single tube has the same shape; the shape of the single tube is three Prismatic shape, including the inner duct 1 at the front end, the middle duct 2 and the outer duct 3 at the tail end. The shape of the inner duct 1 is the same as the shape of the nipple 2, and the outer duct 3 is larger than the shape of the nipple 2 and protrudes from the nipple. The outer surface of 2; the inner conduit hole 7 of the inner conduit 1 is smaller than the takeover hole 8 of the takeover, the inner wall of the inner conduit hole 7 protrudes from the inner wall of the takeover hole 8, and the takeover hole 8 is consistent with the outer conduit hole 9 of the outer conduit 3; The catheter 1, the inner catheter hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com