End face seal structure for rotary compensator and rotary compensator

A technology of rotary compensator and end face sealing, which is applied to expansion compensating devices, adjustable connections, passing elements, etc. for pipelines, can solve the problems of poor sealing effect and easy wear of rotary compensators, and achieves good sealing effect, The effect of reducing torque difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

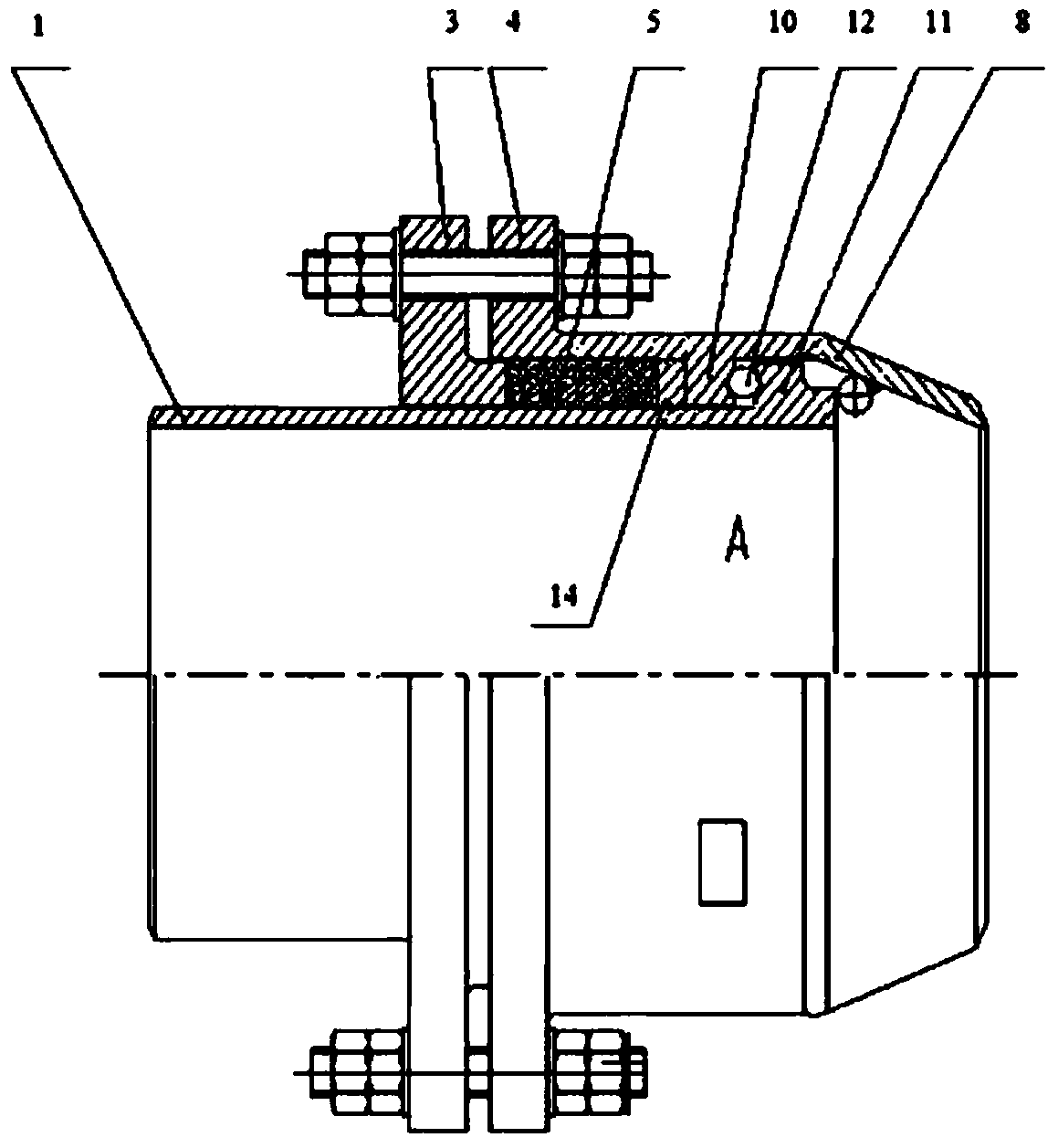

[0026] Such as figure 1 As shown, the rotation compensator of this embodiment includes an inner tube 1, an outer tube 4, a connecting tube 8, a packing flange 3 and an O-shaped end face sealing ring 12. The outer tube 4 and the connecting tube 8 are integrally formed. structure. The outer sleeve 4 is sleeved on the inner pipe 1, one end of the inner pipe 1 passes through the outer sleeve 4 and inserted into the connecting pipe 8, the packing flange 3 is sleeved on the inner pipe 1, and one end extends into the outer sleeve 4. The inner surface of the outer sleeve 4 is provided with a ring-shaped inner boss 10, and the outer surface of the inner tube 1 is provided with a ring-shaped outer boss 11, between the ring-shaped inner boss 10 and the filler flange 3 extending into the end of the outer sleeve 4 There is a sealing packing 5, an anti-impact plate 14 is arranged between the sealing packing 5 and the annular inner boss 10, and a corresponding annular V-shaped groove is opene...

Embodiment 2

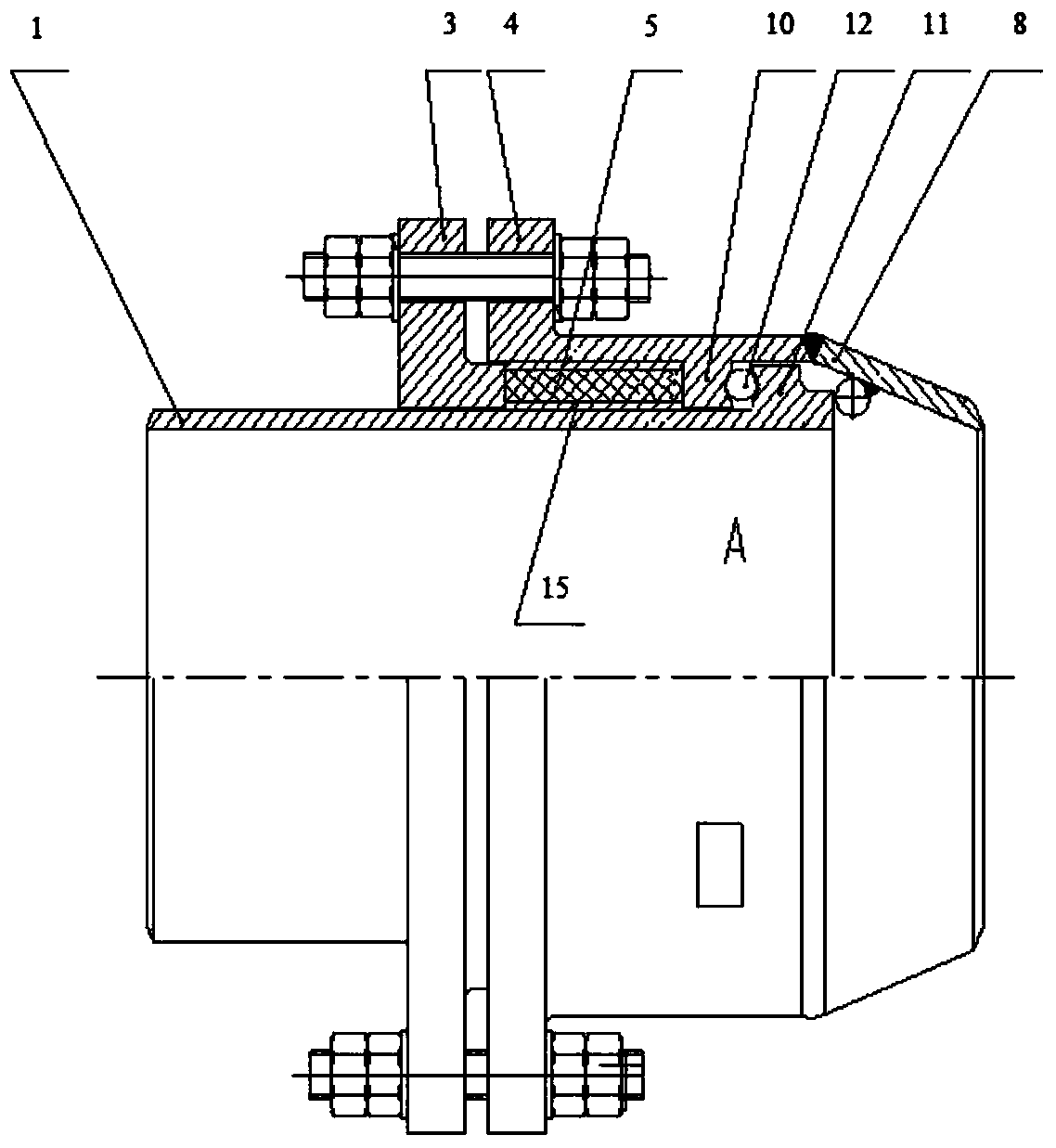

[0028] Such as figure 2 As shown, the rotation compensator in this embodiment includes an inner tube 1, an outer tube 4, a connecting tube 8, a packing flange 3, and an O-shaped end face sealing ring 12. The outer tube 4 is sleeved on the inner tube 1, and the inner tube 1 One end of the tube is inserted into the connecting tube 8 through the outer tube 4, the packing flange 3 is sleeved on the inner tube 1, and one end extends into the outer tube 4. The inner surface of the outer sleeve 4 is provided with a ring-shaped inner boss 10, and the outer surface of the inner tube 1 is provided with a ring-shaped outer boss 11, between the ring-shaped inner boss 10 and the filler flange 3 extending into the end of the outer sleeve 4 A sealing filler 5 is provided, and a wear-resistant carbon fiber layer 15 is provided between the sealing filler 5 and the outer surface of the inner tube 1 and between the sealing filler 5 and the inner surface of the outer tube 4. A corresponding annul...

Embodiment 3

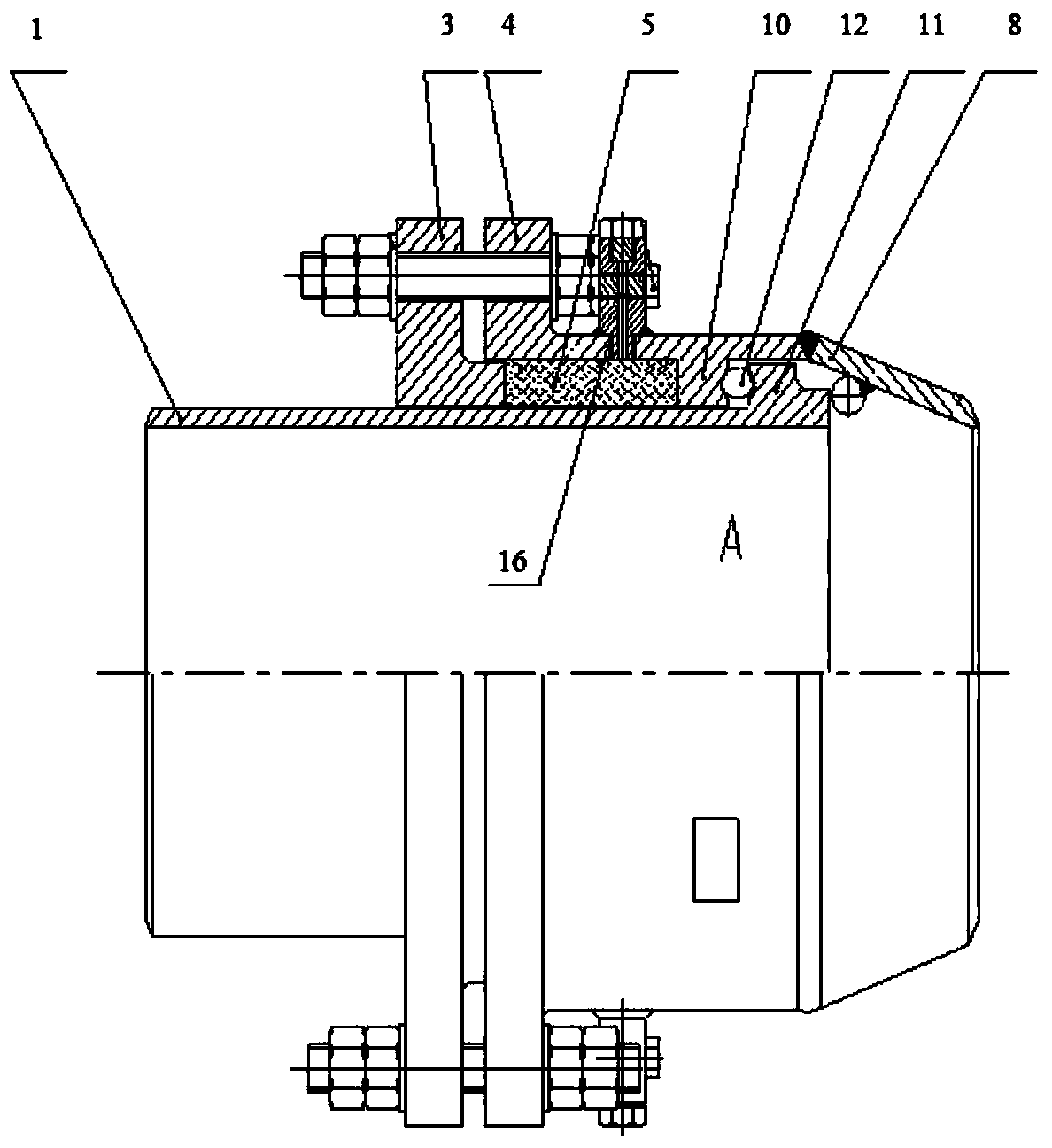

[0030] Such as image 3 As shown, the rotation compensator in this embodiment includes an inner tube 1, an outer tube 4, a connecting tube 8, a packing flange 3, and an O-shaped end face sealing ring 12. The outer tube 4 is sleeved on the inner tube 1, and the inner tube 1 One end of the packing flange 3 is inserted into the connecting pipe 8 through the outer tube 4, the filler flange 3 is sleeved on the inner tube 1, and one end extends into the outer tube 4, the inner surface of the outer tube 4 is provided with an annular inner boss 10, the inner tube A ring-shaped outer boss 11 is provided on the outer surface of 1, a sealing packing 5 is provided between the ring-shaped inner boss 10 and the end of the packing flange 3 that extends into the outer sleeve 4, the ring-shaped inner boss 10 and the ring-shaped outer boss 11 A corresponding annular V-shaped groove is opened on the opposite surfaces, and the O-shaped end face sealing ring 12 is assembled in two annular V-shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com