Acid-resistant green tea concentrated juice and preparation method thereof

A concentrated juice and acid-resistant technology, which is applied in the field of acid-resistant green tea concentrated juice and its preparation, can solve the problems of easy to produce sour odor, quality deterioration, tea beverage flavor and poor stability, etc., to maintain color and flavor, The effect of stable quality, broad market prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to these examples.

[0027] 1. Preparation of acid-resistant green tea concentrate

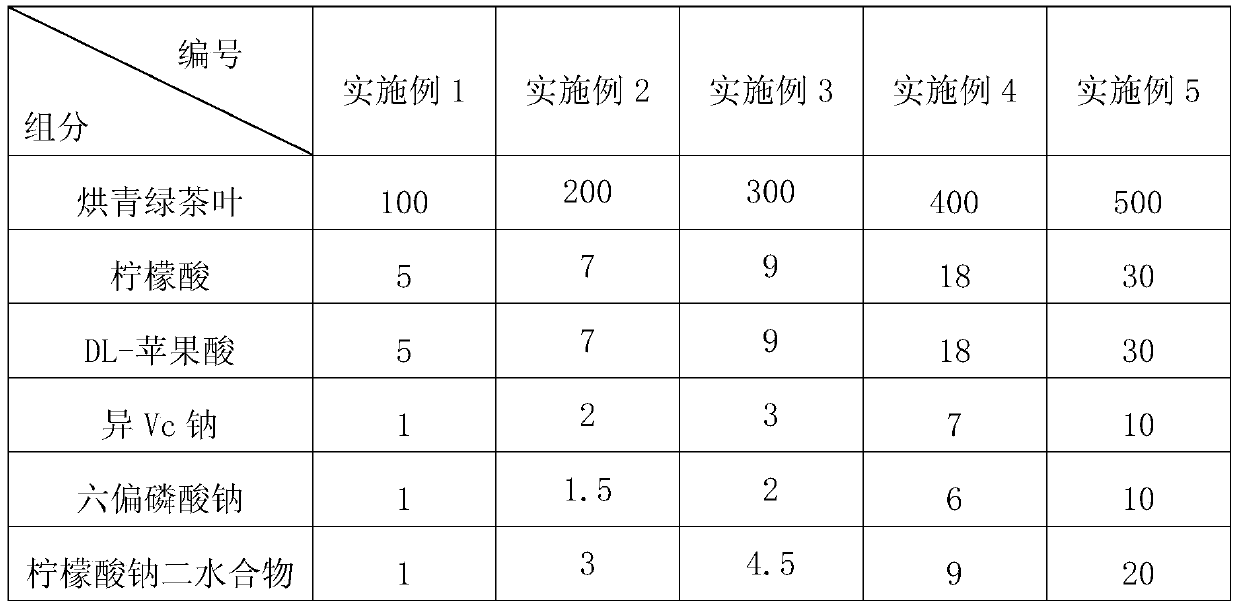

[0028] Embodiments 1-5 are all based on the parts by weight of the raw materials described in Table 1, according to the following steps to prepare acid-resistant green tea concentrated juice:

[0029] Step 1: material selection; select the green tea leaves of the formula amount to ensure the quality of the green tea leaves; in the present invention, the green tea leaves can be selected as any one or more of baked green tea leaves, fried green tea leaves, and jasmine tea leaves. The multiple selection methods can all achieve the same technical effect; for ease of illustration, only selected baked green tea leaves are used as raw materials in Examples 1 to 5;

[0030] Step 2: Pulverizing; putting the green tea leaves in the formula amount into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com