Environmentally friendly recycling device and operating method thereof

A recycling device and working method technology, which is applied in the field of garbage bin placement devices, can solve the problems of pungent sour smell and inability to quickly remove garbage moisture, so as to achieve the effect of avoiding sour smell and rapid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

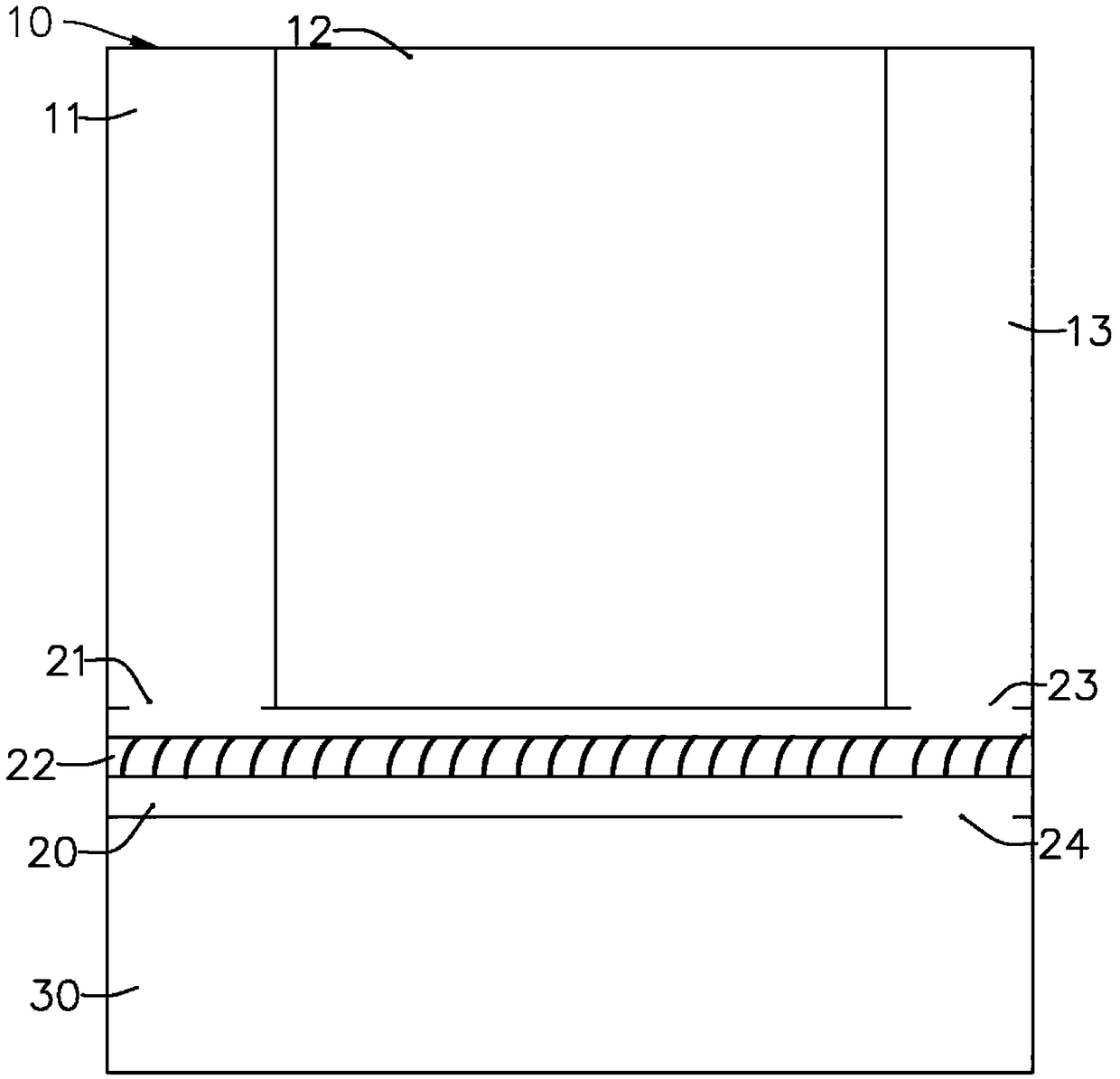

[0029] Such as figure 1 As shown, the environmental protection recovery device of this embodiment includes a box body, and the box body has an upper accommodation space 10 , a middle accommodation space 20 and a lower accommodation space 30 .

[0030] Wherein, the upper accommodating space 10 has a first accommodating body 11 , a second accommodating body 12 and a third accommodating body 13 arranged in sequence in the horizontal direction.

[0031] The central accommodating space 20 has a rotating member arranged in a horizontal direction, the rotating member includes a screw body 22, the central accommodating space 20 has a garbage inlet 21 and a garbage outlet, and the garbage outlet has an upper gas outlet 23 and a lower solid outlet 24.

[0032] The garbage inlet 21 communicates the middle storage space 20 with the first storage body 11 , the upper gas outlet 23 communicates the middle storage space 20 with the third storage body 13 , and the lower solid outlet 24 communi...

no. 2 example

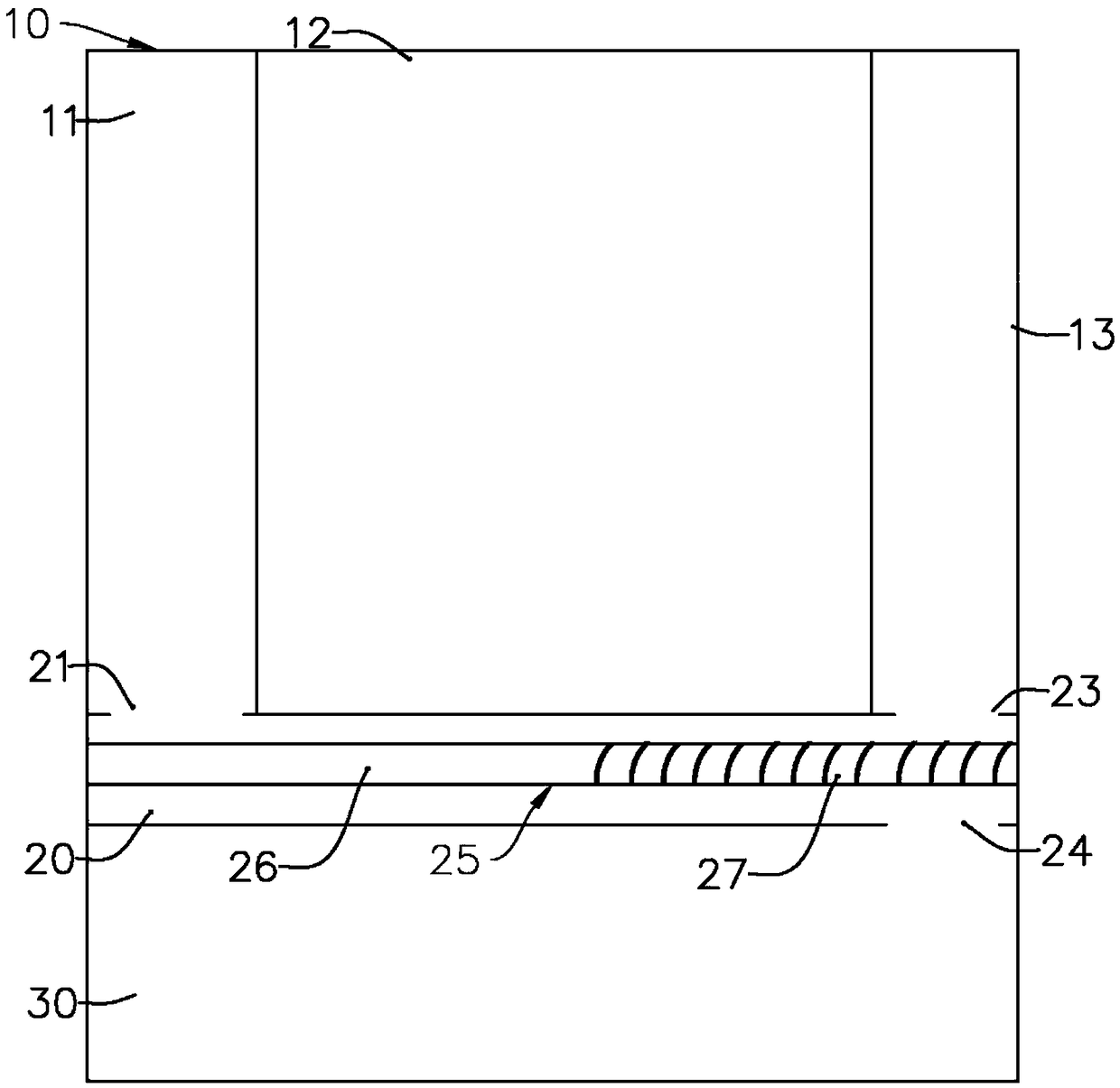

[0038]The environment-friendly recovery device of this embodiment is basically the same as the above-mentioned first embodiment, and only the differences will be described in detail below.

[0039] Such as figure 2 As shown, the rotating member of this embodiment includes a rod body 25, the rod body 25 has a smooth rod body part 26 and a screw rod body part 27, the smooth rod body part 26 is closer to the garbage inlet 21 than the screw rod body part 27, and the heating unit of the heating assembly Also distributed over the smooth shaft portion 26.

[0040] This working method comprises the following steps: the rubbish with moisture is dried and heated under the rotation of the smooth rod part 26, and when the rubbish moves to the screw rod part 27, the screw rod part 27 will dry the dried The garbage is discharged into the lower containing space 30 through the lower solid outlet 24 . In some cases, the water content of some garbage may be relatively high. At this time, the...

no. 3 example

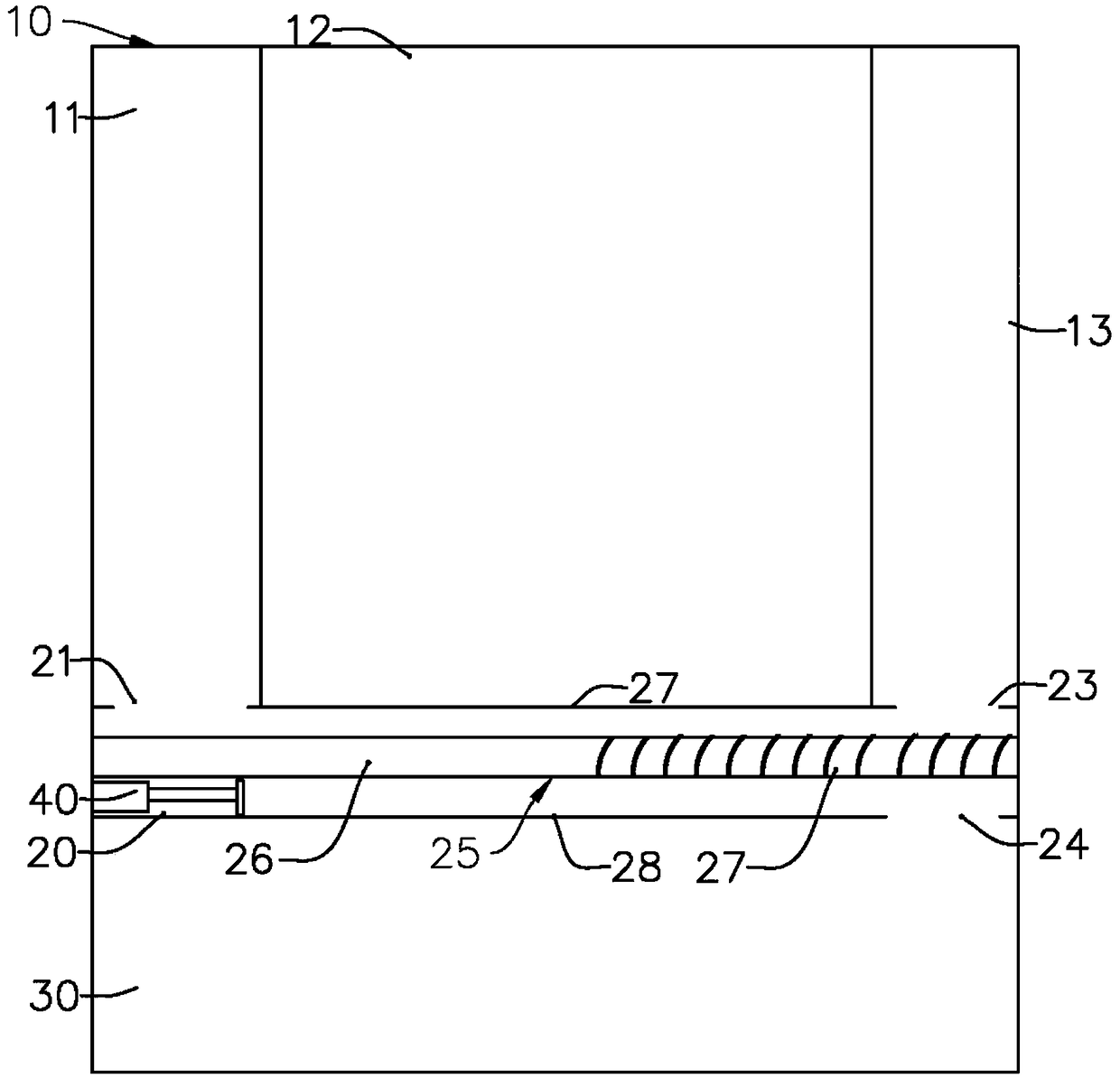

[0042] The environment-friendly recovery device of this embodiment is basically the same as the above-mentioned first embodiment, and only the differences will be described in detail below.

[0043] Such as image 3 As shown, the middle accommodating space 20 of this embodiment has an upper wall 27 and a bottom wall 28, the garbage inlet 21 is arranged on the upper wall 27, and a push-pull assembly 40 is arranged in the middle accommodating space 20, and the push-pull assembly 40 is arranged on the rod body 25 and the position between the bottom wall 28. The push-pull assembly can, for example, use a cylinder or a hydraulic cylinder or a motor screw to move in the horizontal direction, so that the push plate can drive the dried garbage to move downstream.

[0044] The working method includes the following steps: the rubbish with moisture is dried and heated under the rotation of the smooth rod part 26, and when the moisture of the rubbish is dried, the push-pull assembly 40 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com