Marking device under electronic control

A marking device, electronic manipulation technology, applied in workshop equipment, manufacturing tools, etc., can solve the problem of time-consuming and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, content of the invention will be further described:

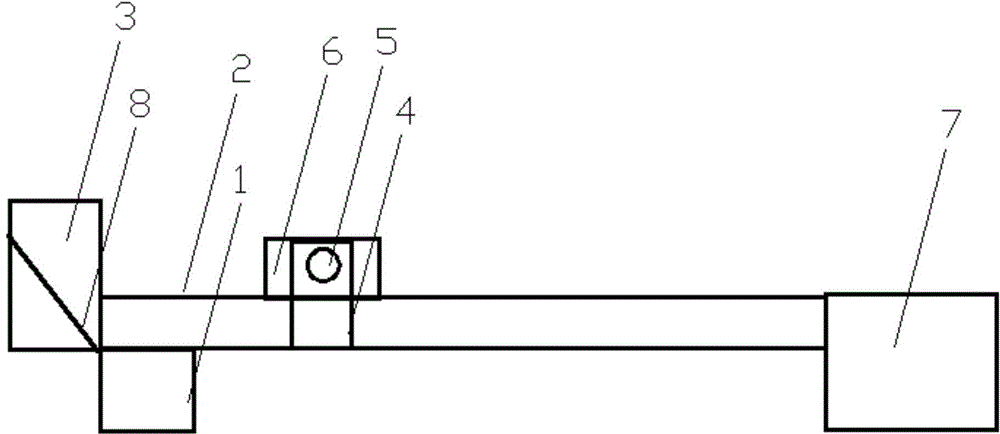

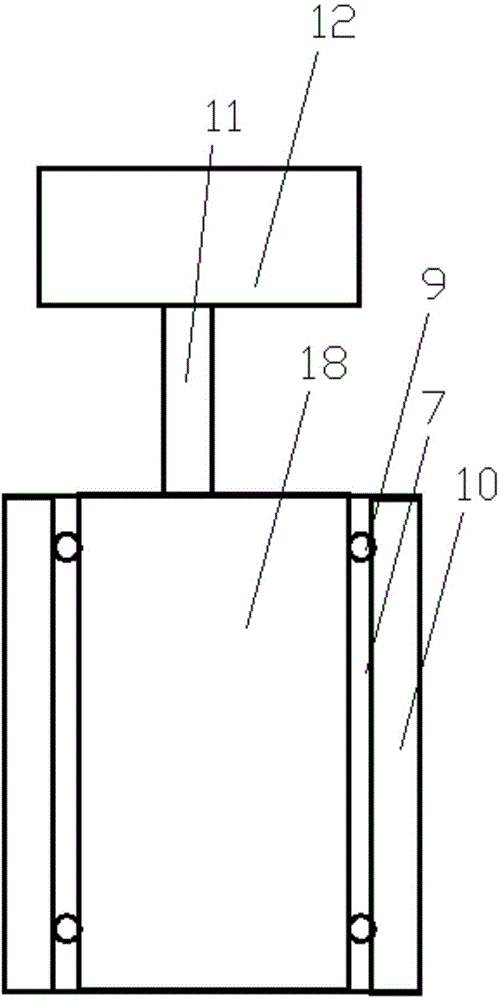

[0017] refer to figure 1 and figure 2 As shown, the engraving marking device under electronic control includes a conveyor belt 2 with a conveyor belt electric control system 1, the starting end of the conveyor belt 2 is connected to a mechanical component output cabinet 3, and one of the conveyor belt 2 is facing the set punching position. A pneumatic manipulator 4 with a photoelectric sensor 5 is arranged on the side, the sensing range of the photoelectric sensor 5 can cover the punching position, and a punching machine 6 is arranged on the other side of the conveyor belt 2 facing the set punching position , the end of the conveyor belt 2 is connected with the mechanical parts input cabinet 7 after punching. The mechanical parts output cabinet 3 is a cabinet structure, and the inside of the mechanical parts output cabinet 3 is an inclined plate 8, and a side panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com