Thermal mud phosphorus type phosphate rock powder binder

A phosphate rock powder and binder technology, applied in the field of phosphate rock powder binder, can solve the problems of difficulty in controlling the chemical composition of finished products and waste, many raw materials added, lengthy production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

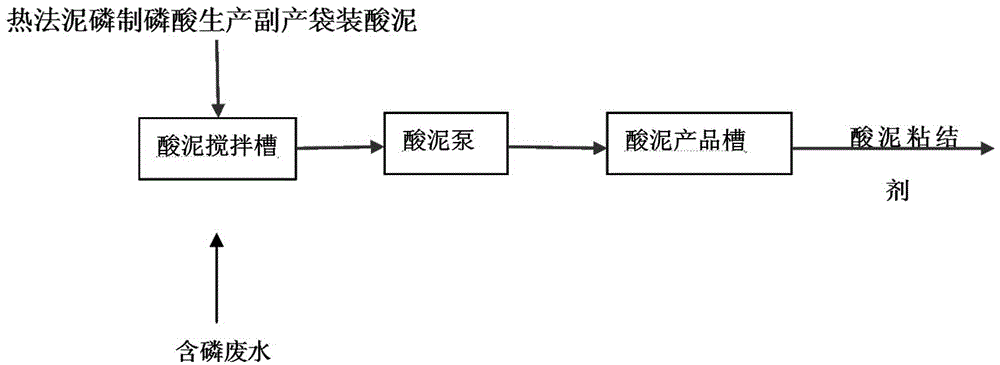

Image

Examples

Embodiment 1

[0012] A phosphate rock powder binder, adding phosphorus-containing waste water produced in the production process of thermal yellow phosphorus into the acid mud mixing tank, the addition amount is 50% of the tank volume, starting the agitator, and then filtering the phosphoric acid produced from thermal mud phosphorus The percentage of free phosphoric acid produced is 25%, P 2 o 5 Slowly add paste-like acid mud with a percentage content of 31%, stir evenly and mix to form a suspension with a solid phase of 70% and a liquid phase of 30%, making a solid content of 70%, P 2 o 5 The percentage content is 28% phosphate rock powder binder.

[0013] After the binder and the phosphate rock powder are stirred and mixed in proportion, the phosphate rock powder is used in a briquette drying process or a granulation and roasting process to produce phosphate rock pellets. P in phosphate rock pellets 2 o 5 content increased by 5%.

Embodiment 2

[0015] A phosphate rock powder binder, adding phosphorus-containing waste water produced in the production process of thermal yellow phosphorus into the acid mud mixing tank, the addition amount is 50% of the tank volume, starting the agitator, and then filtering the phosphoric acid produced from thermal mud phosphorus The percentage of free phosphoric acid produced is 28%, P 2 o 5 Slowly add paste-like acid mud with a percentage content of 33%, stir evenly and mix to form a suspension with a solid phase of 75% and a liquid phase of 25%, making a solid content of 75%, P 2 o 5 The percentage content is 30% phosphate rock powder binder.

[0016] After the binder and the phosphate rock powder are stirred and mixed in proportion, the phosphate rock powder is used in a briquette drying process or a granulation and roasting process to produce phosphate rock pellets. P in phosphate rock pellets 2 o 5 content increased by 6%.

Embodiment 3

[0018] A phosphate rock powder binder, adding phosphorus-containing waste water produced in the production process of thermal yellow phosphorus into the acid mud mixing tank, the addition amount is 50% of the tank volume, starting the agitator, and then filtering the phosphoric acid produced from thermal mud phosphorus The percentage of free phosphoric acid produced is 30%, P 2 o 5 Slowly add paste-like acid mud with a percentage content of 35%, stir evenly and mix to form a suspension with 80% solid phase and 20% liquid phase, and make a solid content of 80%, P 2 o 5 The percentage content is 32% phosphate rock powder binder.

[0019] After the binder and the phosphate rock powder are stirred and mixed in proportion, the phosphate rock powder is used in a briquette drying process or a granulation and roasting process to produce phosphate rock pellets. P in phosphate rock pellets 2 o 5 content increased by 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com