Liquid-solid phase adjustment type ground phosphate rock binder

A phosphate rock powder, liquid-solid phase technology, applied in the field of phosphate rock powder binder, can solve the problems of adding too many raw materials, cumbersome, lengthy production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

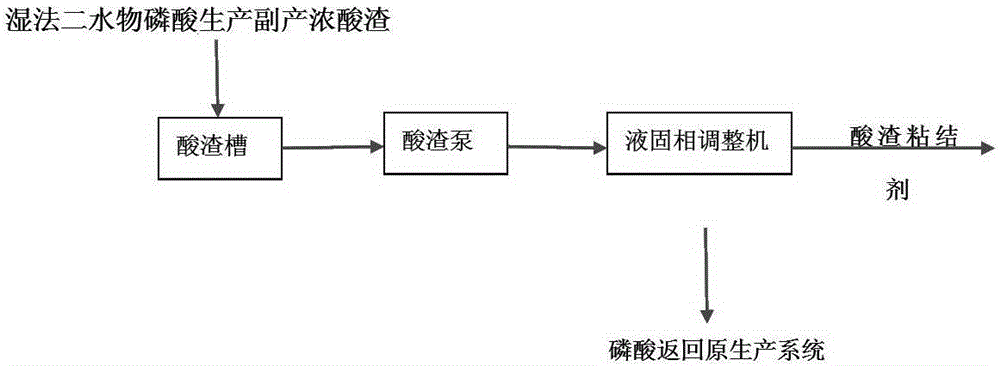

[0011] A kind of phosphate rock powder binding agent, the solid matter content that produces after concentrating in dihydrate process wet-process phosphoric acid production is 10%, P 2 o 5 The acid slag with a percentage content of 45% is stored in the acid slag tank, and is pumped into the liquid-solid phase regulator with an acid slag pump to make a solid content of 30%, P 2 o 5 The percentage content is 35% phosphate rock powder binder. After the binder and the phosphate rock powder are stirred and mixed in proportion, the phosphate rock pellets are produced through the processes of briquette forming, drying or granulation and roasting. P in phosphate rock pellets 2 o 5 content increased by 10%.

Embodiment 2

[0013] A kind of phosphate rock powder binding agent, the solid matter content that produces after concentrating in dihydrate process wet-process phosphoric acid production is 15%, P 2 o 5 The acid slag with a percentage content of 43% is stored in the acid slag tank, and is pumped into the liquid-solid phase regulator with an acid slag pump to make a solid content of 40%, P 2 o 5 The percentage content is 33% phosphate rock powder binder. After the binder and the phosphate rock powder are stirred and mixed in proportion, the phosphate rock pellets are produced through the processes of briquette forming, drying or granulation and roasting. P in phosphate rock pellets 2 o 5 content increased by 9%.

Embodiment 3

[0015] A kind of phosphate rock powder binding agent, the solid matter content that produces after concentrating in dihydrate process wet-process phosphoric acid production is 20%, P 2 o 5 The acid slag with a percentage content of 40% is stored in the acid slag tank, and is pumped into the liquid-solid phase regulator with an acid slag pump to make a solid content of 50%, P 2 o 5 The percentage content is 30% phosphate rock powder binder. After the binder and the phosphate rock powder are stirred and mixed in proportion, the phosphate rock pellets are produced through the processes of briquette forming, drying or granulation and roasting. P in phosphate rock pellets 2 o 5 content increased by 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com