A method for forming and drying phosphate rock powder pressure balls

A technology of briquetting forming and phosphate rock powder, applied in the field of phosphorus chemical industry, can solve the problems of cumbersome, lengthy production process, many raw materials added, etc., and achieve the effect of efficient circulation and comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

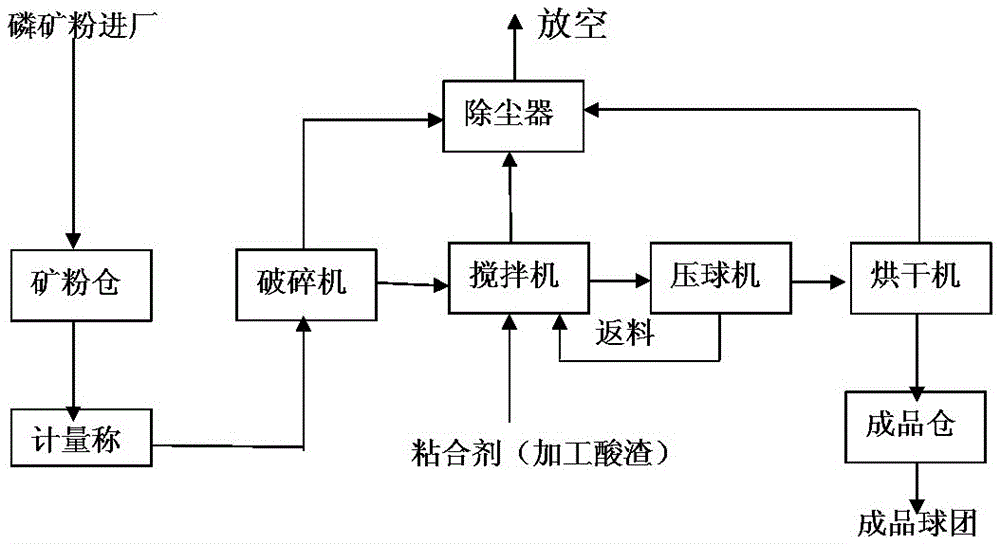

Image

Examples

Embodiment 1

[0011] After the phosphate rock is crushed, screened, dried and homogenized, it is made into a phosphate rock powder with a water content of 5% by weight and a particle size of ≤10mm. The weight percentage of solids made from product acid slag is 20%, P 2 o 5 The weight percent content is 45% binder, the proportioning ratio of binder and phosphate rock powder weight ratio is 3: 7, stirs evenly for 6 minutes, obtains the mixture that the weight percent moisture is 9%, sends into press Press the ball machine into a ball with a diameter of 30mm, and then dry it at a temperature of 400°C for 40 minutes to make phosphate rock pellets for yellow phosphorus production. The P in the phosphate rock pellets 2 o 5 content increased by 10%.

Embodiment 2

[0013] After the phosphate rock is crushed, screened, dried and homogenized, it is made into a phosphate rock powder with a water content of 7% by weight and a particle size of ≤10mm. The weight percentage of solids made from product acid slag is 40%, P 2 o 5 The weight percent content is 38% of the binder, the weight ratio of the binder to the phosphate rock powder is 4:6, and it is evenly stirred for 5 minutes to obtain a mixture with a weight percent water content of 10%, which is sent into the press Press the ball machine into a ball with a diameter of 40mm, and then dry it at a temperature of 430°C for 45 minutes to make phosphate rock pellets for the production of yellow phosphorus. The P in the phosphate rock pellets 2 o 5 content increased by 9%.

Embodiment 3

[0015] After crushing, sieving, drying and homogenizing pretreatment, phosphate rock powder is made into phosphate rock powder with a water content of 8% by weight and a particle size of ≤10mm, which is sent to a mixer and produced by adding dihydrate wet-process phosphoric acid. The weight percentage of solids made from intermediate product acid slag is 50%, P 2 o 5 The weight percent content is 35% of the binder, the weight ratio of the binder to the phosphate rock powder is 4:6, and it is stirred evenly for 4 minutes to obtain a mixture with a weight percent water content of 12%, which is sent into the press Press the ball machine into a ball with a diameter of 50mm, and then dry it at a temperature of 450°C for 50 minutes to make phosphate rock pellets for the production of yellow phosphorus. The P in the phosphate rock pellets 2 o 5 content increased by 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com