A kind of nano-carbon composite diatomite and preparation method thereof

A technology of diatomite and nano-carbon, which is applied in the direction of conductive coatings and coatings, can solve the problems of easy powder falling, increased indoor dust volume, difficult cleaning, etc., achieves improved strength and wear resistance, and reduces electrostatic adsorption , the effect of reducing the speed of dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

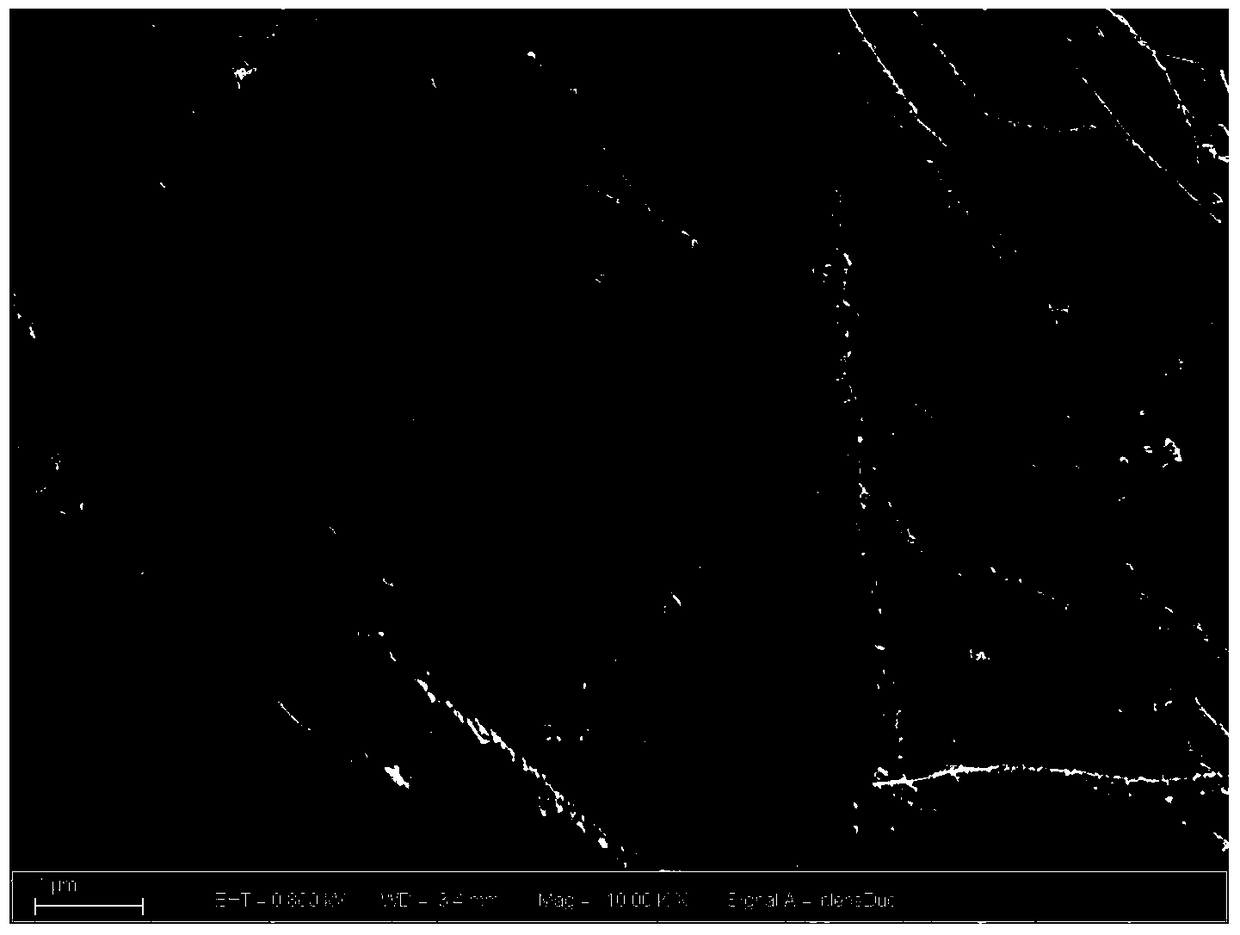

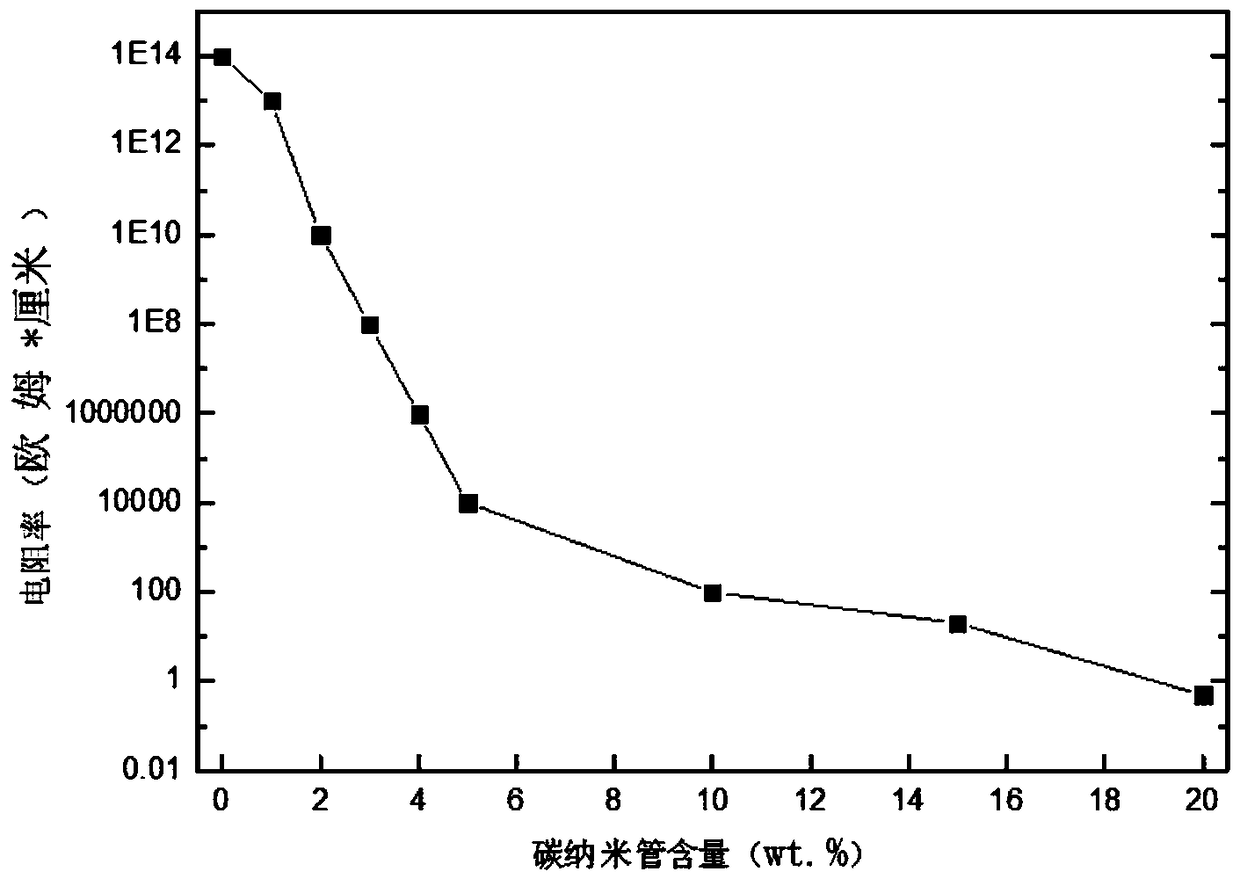

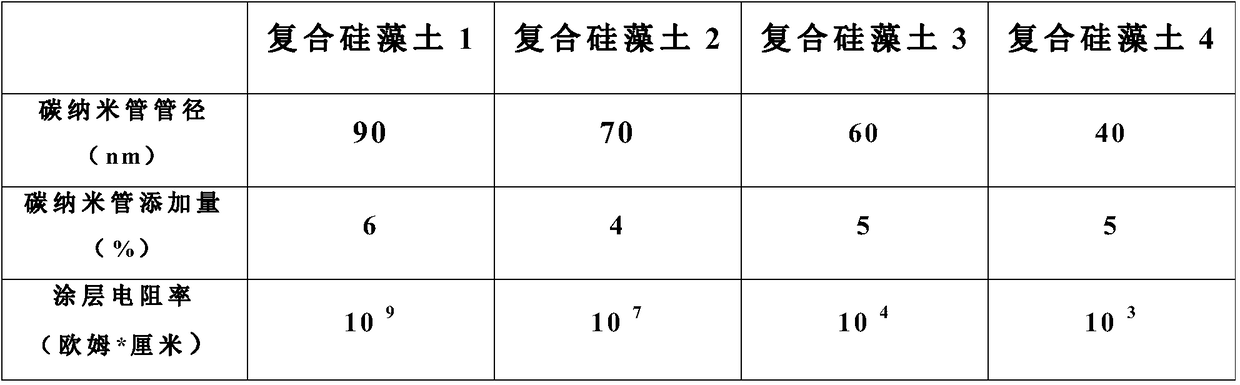

[0021] Choose diatomaceous earth, the main component is SiO 2 , while containing part of Al 2 o 3 , CaO, MgO, etc. and a small amount of organic matter, the particle size is about 0.7-1.5μm. Carbon nanotubes are selected as additives, with a diameter of about 70 nm and an average length of about 5 μm. Diatomaceous earth and carbon nanotubes were vacuum-dried at 105° C. and -0.9 MPa for 4 hours, respectively. Then it was tested that the water content of diatomaceous earth and carbon nanotubes were both less than 0.5wt.%. 100 g of carbon nanotubes and 900 g of diatomaceous earth were successively loaded into a vacuum stirrer, and then the stirring was started when the vacuum was evacuated to about -0.1 MPa. After timing for about 1.5 hours, the stirring was stopped, and the material was collected to obtain a composite diatomite containing 4 wt.% of carbon nanotubes. According to the mud coating test, compared with the diatomite without carbon nanotubes, the surface resistan...

Embodiment 2

[0023] Choose diatomaceous earth, the main component is SiO 2 , while containing part of Al 2 o 3 , CaO, MgO, etc. and a small amount of organic matter, the particle size is about 0.7-1.5μm. Carbon nanotubes are selected as additives, with a diameter of about 60 nm and an average length of about 5 μm. Diatomaceous earth and carbon nanotubes were vacuum-dried at 105° C. and -0.9 MPa for 4 hours, respectively. Then it was tested that the water content of diatomaceous earth and carbon nanotubes were both less than 0.5wt.%. 50 g of carbon nanotubes and 950 g of diatomaceous earth were successively loaded into a vacuum stirrer, and then the stirring was started when the vacuum was reduced to about -0.1 MPa. After timing for about 3 hours, the stirring was stopped, and the material was collected to obtain a composite diatomite containing 5 wt.% of carbon nanotubes. According to the mud coating test, compared with the diatomite without carbon nanotubes, the surface resistance of...

Embodiment 3

[0025] Choose diatomaceous earth, the main component is SiO 2 , while containing part of Al 2 o 3 , CaO, MgO, etc. and a small amount of organic matter, the particle size is about 0.1-0.5μm. Carbon nanotubes are selected as additives, with a diameter of about 40 nm and an average length of about 5 μm. Diatomaceous earth and carbon nanotubes were vacuum-dried at 105° C. and -0.9 MPa for 4 hours, respectively. Then it was tested that the water content of diatomaceous earth and carbon nanotubes were both less than 0.5wt.%. 50 g of carbon nanotubes and 950 g of diatomaceous earth were successively loaded into a vacuum stirrer, and then the stirring was started when the vacuum was reduced to about -0.1 MPa. After timing for about 3 hours, the stirring was stopped, and the material was collected to obtain a composite diatomite containing 5 wt.% of carbon nanotubes. According to the mud coating test, compared with the diatomite without carbon nanotubes, the surface resistance of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com