Carriage device and apparatus comprising the same

A sliding frame and component technology, which is applied to shafts and bearings, linear motion bearings, printing, etc., can solve the problem of high replacement frequency of bearing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

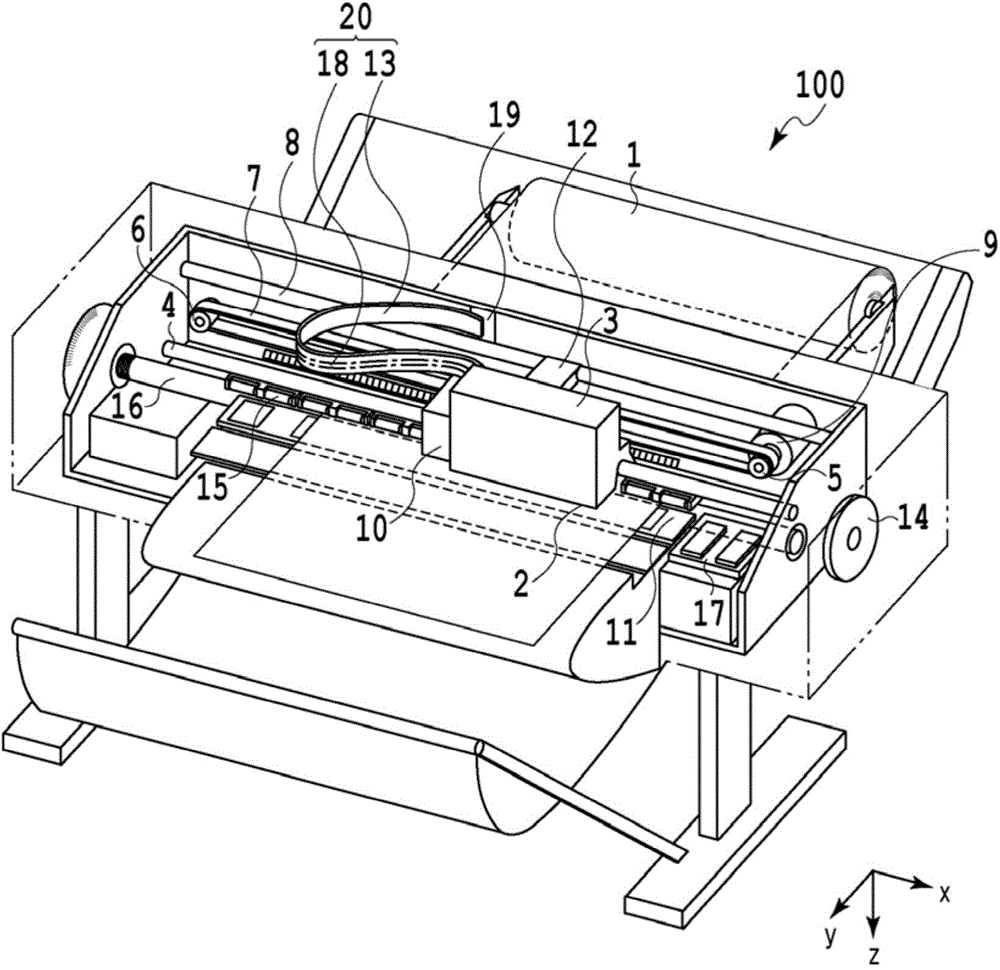

[0030] figure 1 It is a schematic perspective view showing the overall configuration of the printing apparatus 100 . The printing device 100 is an inkjet printing device that performs printing by ejecting ink droplets from a print head, and is capable of printing and recording on a wide recording medium. In addition, the printing apparatus 100 is a printing apparatus of a serial scanning method that performs recording by repeatedly performing a conveying operation of a recording medium and a printing operation of ejecting ink droplets from the printing head as the carriage on which the printing head moves. . As the recording medium, recording paper, a plastic sheet, etc. can be used, and here, a case where recording is performed on the sheet 1 as continuous paper as the recording medium will be described.

[0031] like figure 1 As shown, the printing apparatus 100 includes a carriage 3 , a first guide member 4 (guide member), a second guide member 8 , a transport roller 16 ...

no. 2 Embodiment approach

[0070] In the second embodiment, the structure of the bearing is different from that of the first embodiment. The other configurations are the same as those of the first embodiment, and thus description thereof will be omitted.

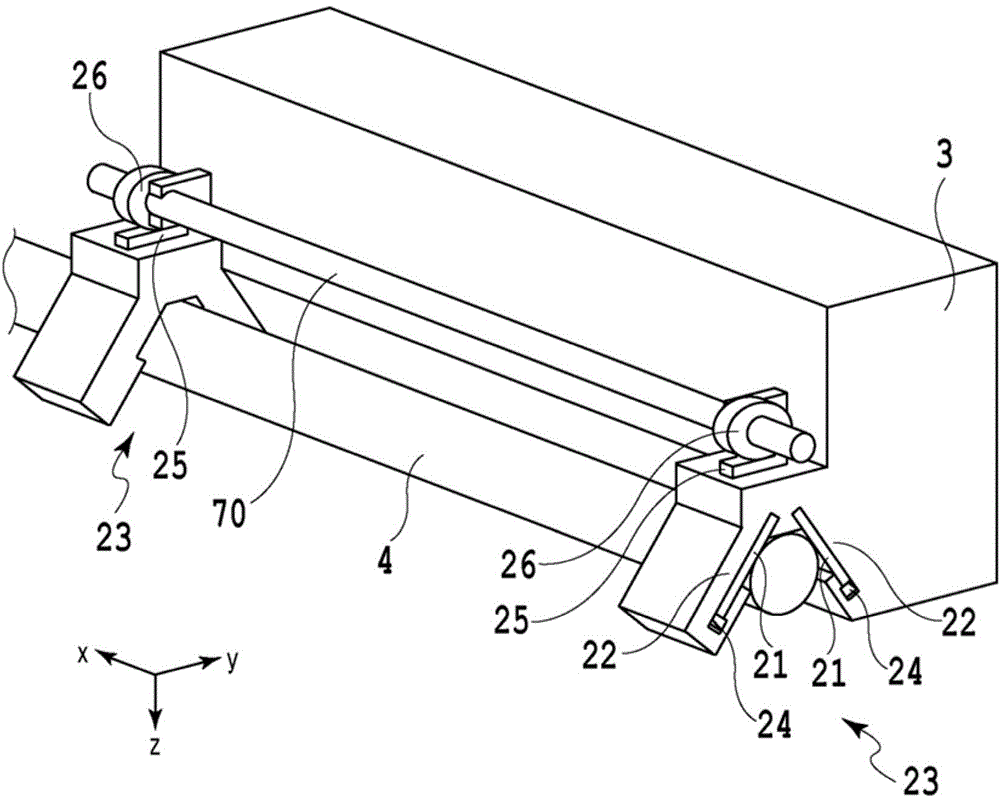

[0071] Figure 10 It is a perspective view showing the carriage 3 and the first guide member 4 . like Figure 10 As shown, bearings 29 are provided at both ends of the carriage 3 in the x direction. A bearing member 27 is arranged on each bearing 29 . The bearing member 27 located on one end side in the x direction is connected to the bearing member 27 located on the other end side by a link 30 .

[0072] Figure 11 is a cross-sectional view showing the carriage 3 and the first guide member 4, showing the Figure 10 The resulting state is viewed from the upstream side in the x-direction shown towards the downstream side. like Figure 11 As shown, the bearing 29 has two support portions 28 each supporting a bearing member 27 (contact pad). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com