Guide carriage having a rolling-body guide part made from an elastomer

A technology of guided vehicles and rolling elements, which is applied in the field of guided vehicles, can solve problems such as poor sealing effects, and achieve good sealing effects, low cost, and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

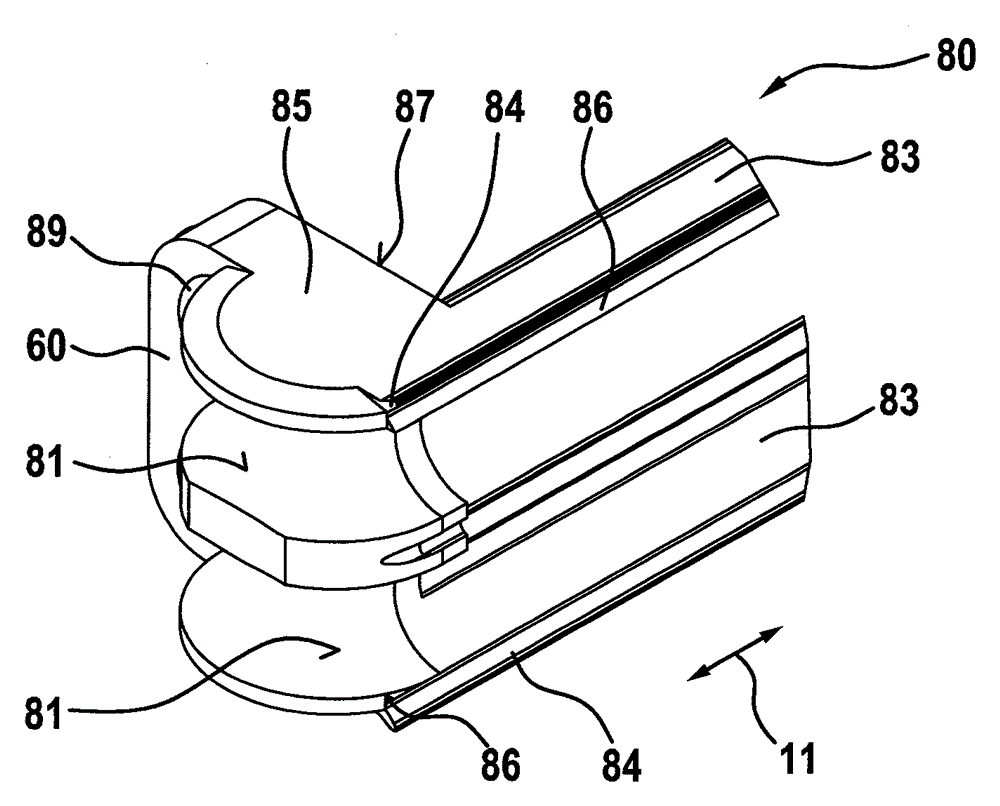

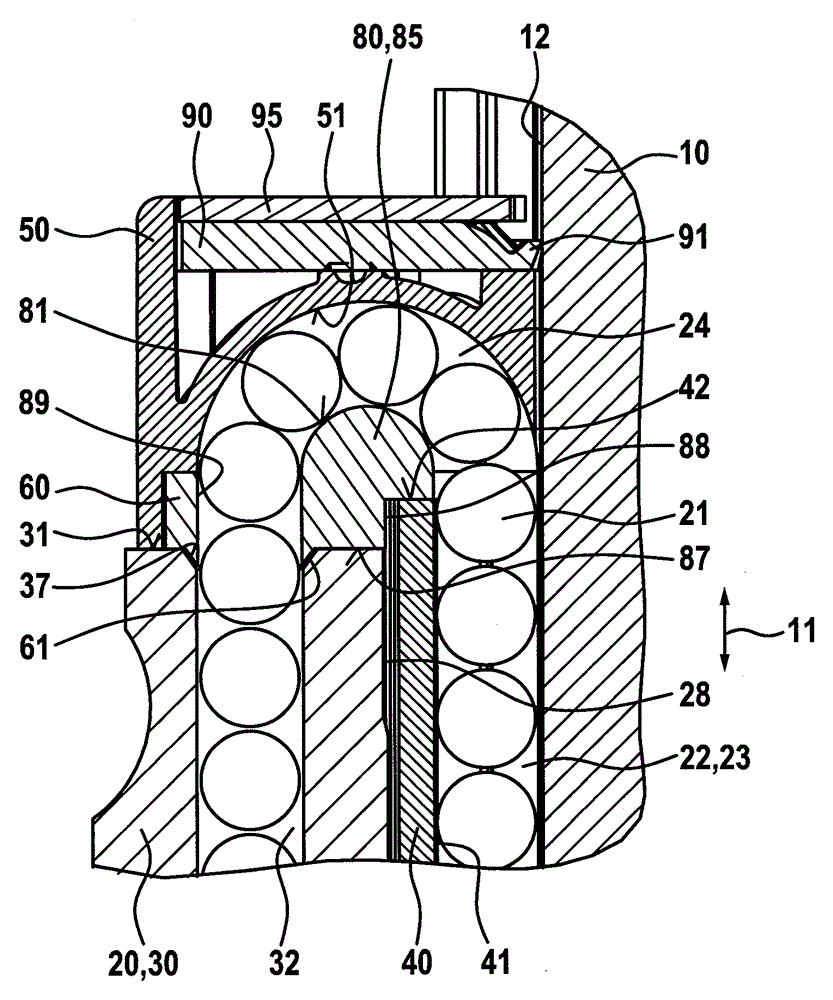

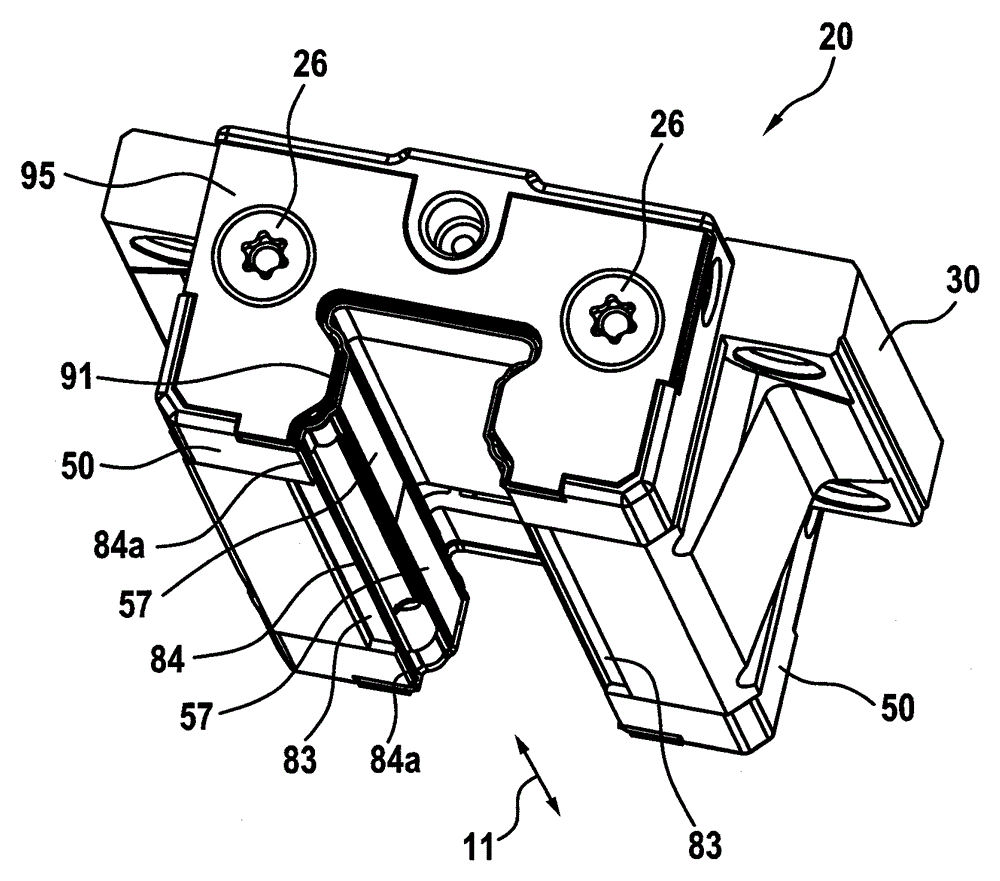

[0077] figure 1 An exploded view of a guided vehicle 20 according to the invention is shown. The guide carriage 20 comprises a main body 30 made of unhardened steel, which extends in the longitudinal direction 11 with a substantially constant, U-shaped cross-sectional shape. Arranged on the inside of the U-legs 35 are respectively V-shaped grooves 33 , against which a separate running track pad 40 of hardened rolling bearing steel rests in each case. Two running track pads 40 extend in the longitudinal direction 11 with a substantially constant cross-sectional shape, wherein the running track pads each have two vehicle running tracks 41a; 41b, so that the guide vehicle 20 has a total of four rows of rolling bodies ( figure 2 The reference number is 21).

[0078] An end cap 50 with an inner longitudinal end face 55 abuts directly on two opposite, planar longitudinal end faces 31 of the main body 30 . The two end caps 50 are designed identically, here being produced from pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com