A Composite Damping Vibration Isolator

A composite damping and vibration isolator technology, applied in the direction of shock absorber, shock absorber-spring combination, shock absorber, etc., can solve the problems of small damping and low bearing capacity, achieve large bearing capacity and improve anti-explosive shock , the effect of high longitudinal and lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

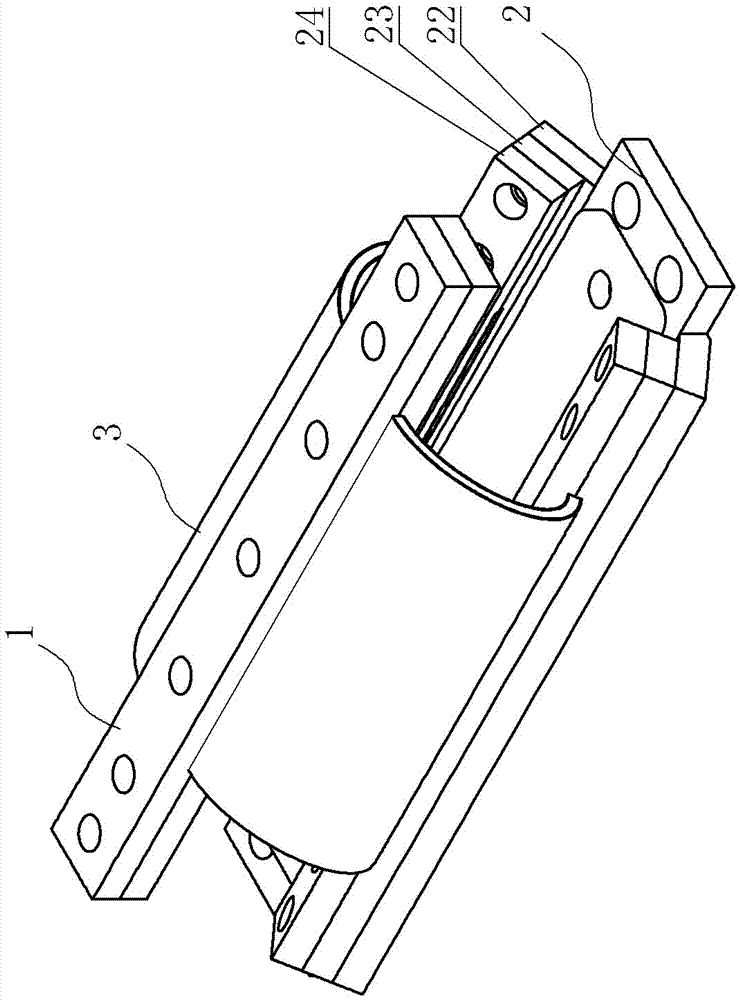

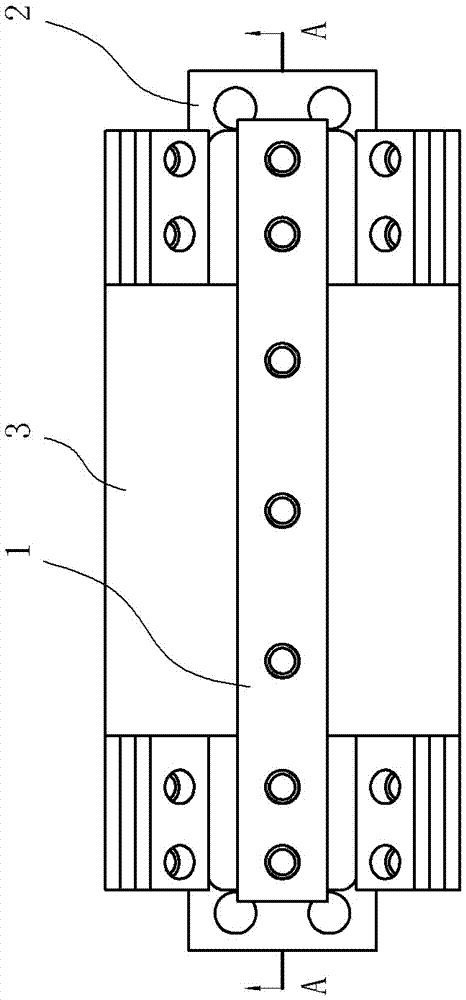

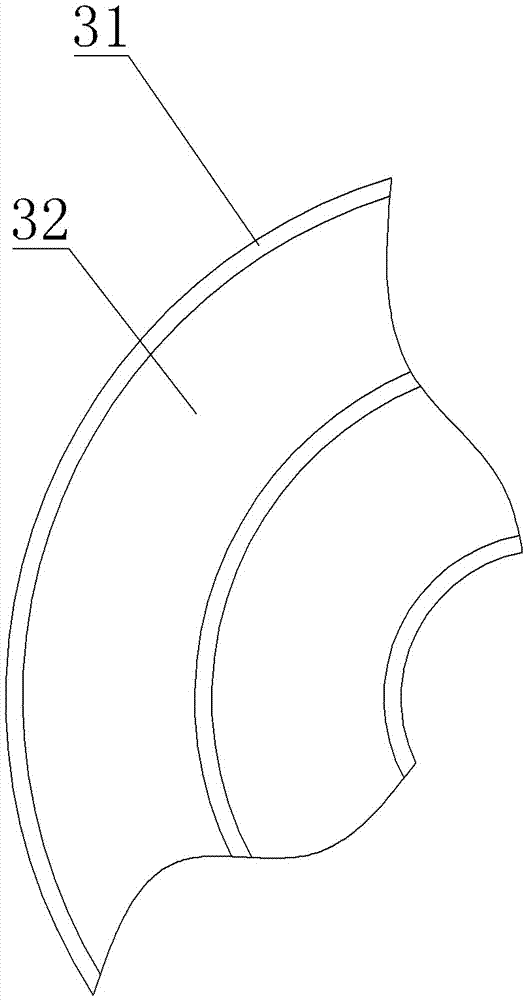

[0025] Such as Figure 1 to Figure 2 As shown, a composite damping vibration isolator includes an upper connecting piece 1 and a lower connecting piece 2, and both sides of the upper connecting piece 1 are connected to both sides of the lower connecting piece 2 through a vibration damping assembly 3, as shown in Figure 4 As shown, the damping assembly 3 includes stacked steel plates 31, and a rubber layer 32 is provided between adjacent steel plates 31, as figure 1 , Figure 4 As shown, the steel plate 31 is curved in an arc shape as a whole, and has elasticity; the steel plate 31 can also be in a curved shape as a whole, but it needs to be elastic. Wherein, the upper connecting piece 1 is used for connecting the object requiring vibration isolation, and the lower connecting piece 2 is used for connecting the vibrating object, and the installation directions of the upper connecting piece 1 and the lower connecting piece can be adjusted mutually.

[0026] One vibration dampi...

Embodiment 2

[0032] The difference between embodiment two and embodiment one is: as Figure 5 , Figure 6 As shown, a hydraulic damper 4 is provided between the upper connecting piece 1 and the lower connecting piece 2, the movable end of the hydraulic damper 4, that is, the upper end of the hydraulic damper 4, faces the upper connecting piece 1, and the fixed end of the hydraulic damper 4 , that is, the lower end of the hydraulic damper is fixed on the lower connecting piece 2. Such as Figure 7 As shown, there are two hydraulic dampers 4, which are respectively fixed on both sides of the lower connecting piece 2. The number of hydraulic dampers 4 can also be one or more.

[0033] There is a gap between the movable end of the upper connecting piece 1 and the hydraulic damper 4 , and through the setting of the gap, it is possible to control the independent action of the vibration-damping assembly 3 and the joint action of the vibration-damping assembly 3 and the damper 4 .

[0034] Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com