Airplane splint measuring tool

A technology for measuring tooling and tooling, applied in the field of machinery, can solve the problems of difficult alignment, difficult card installation, time-consuming and laborious reinstallation, etc., to achieve the effect of shortening the cycle, easy card installation, and avoiding time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below.

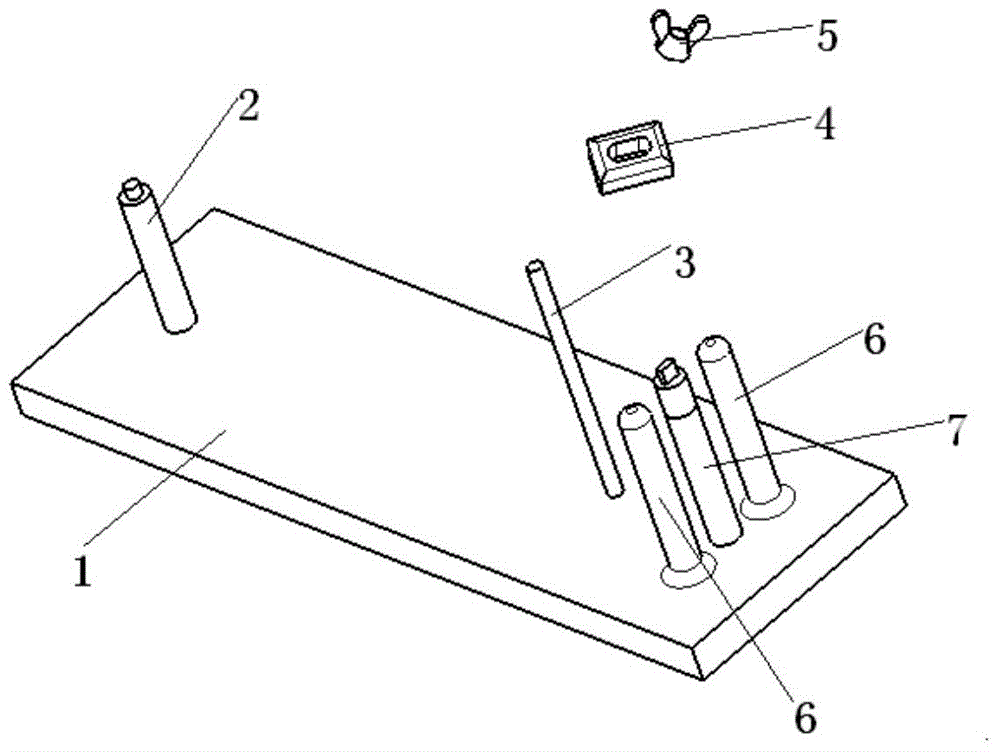

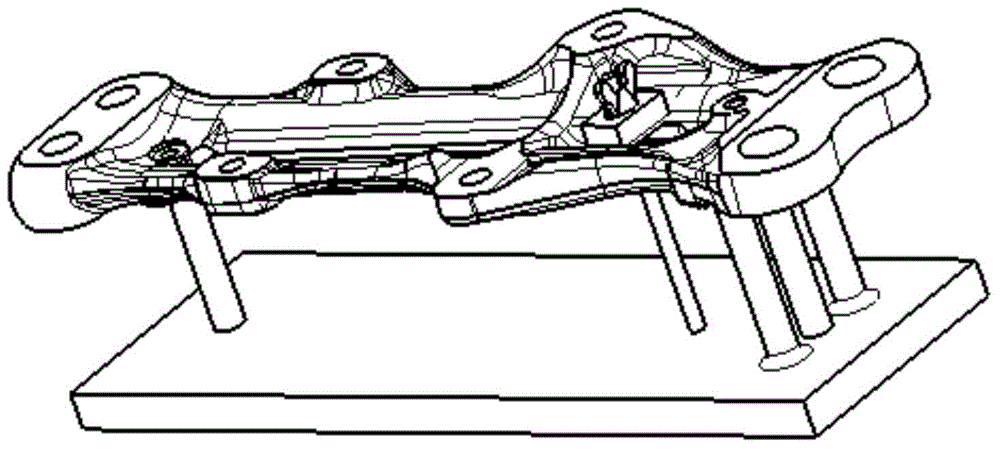

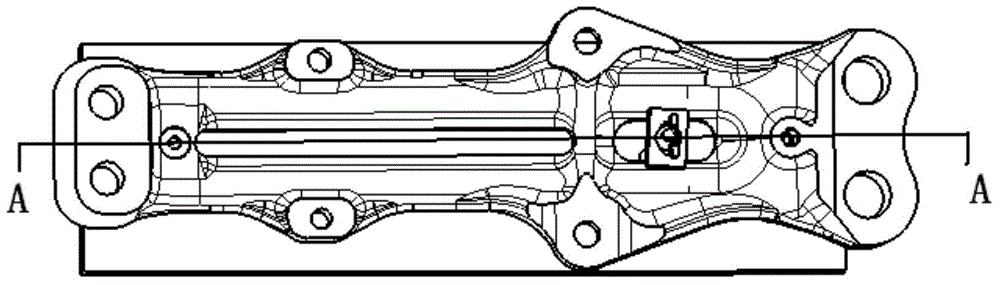

[0012] The measuring tool of the aircraft splint provided by the invention, such as figure 1 , 2 , 3, and 4, including:

[0013] Tooling base 1, the tooling base 1 is a cuboid, a step cylinder 2 is provided on the upper surface of the tooling base 1 near one end, and a supporting cylinder 6 is arranged side by side on the upper surface of the tooling base 1 near the other end. A positioning cylinder 7 is arranged between the cylinders 6, and an externally threaded cylinder 3 is arranged between the step cylinder 2 and the positioning cylinder 7, and the externally threaded cylinder 3 passes upward through the part to be measured, and the pressing block 4 passes through the externally threaded cylinder 3 and is pressed on the upper surface, and the top of the briquetting block 4 is screwed and pressed tightly with the externally threaded cylinder 3 by a stabilizing device 5 with a threaded hole.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com