Tool for measuring airplane blade filling material

A technology for measuring tooling and fillers, applied to measuring devices, workpiece clamping devices, manufacturing tools, etc., can solve problems such as data analysis of unfavorable parts, and achieve the effects of convenient data analysis, avoiding time waste, and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

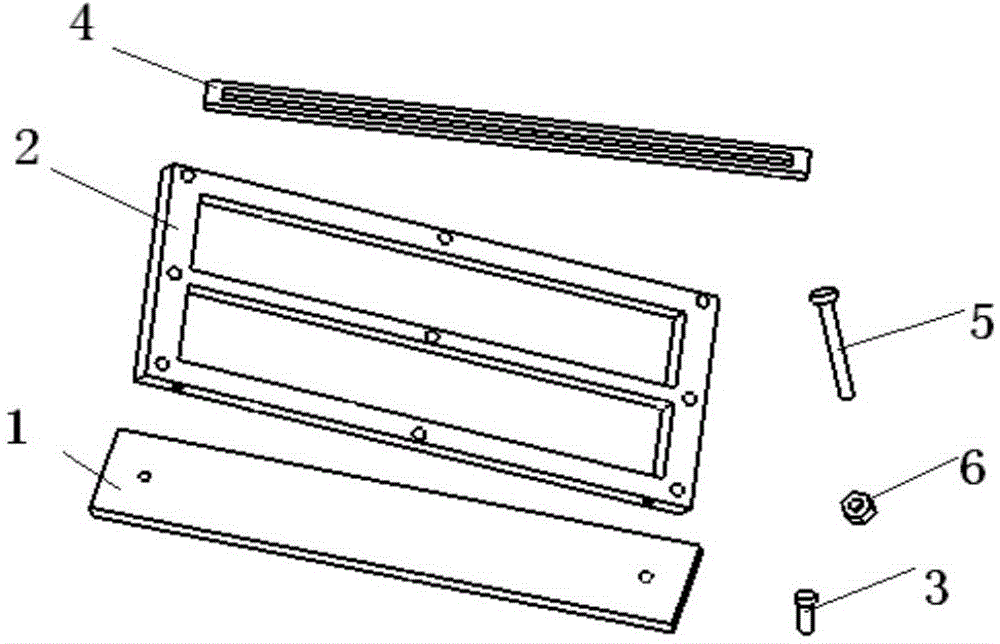

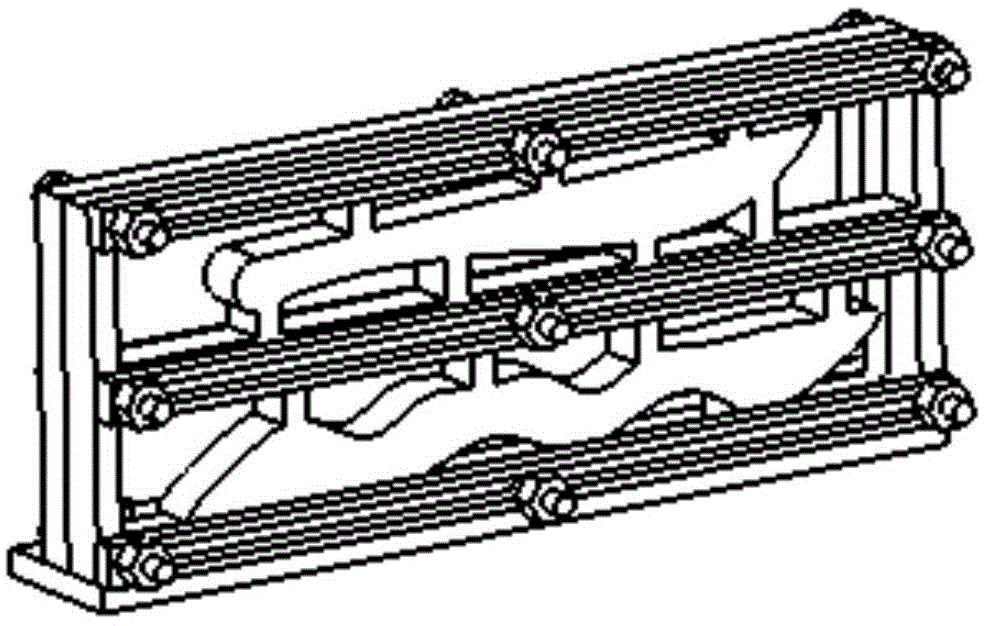

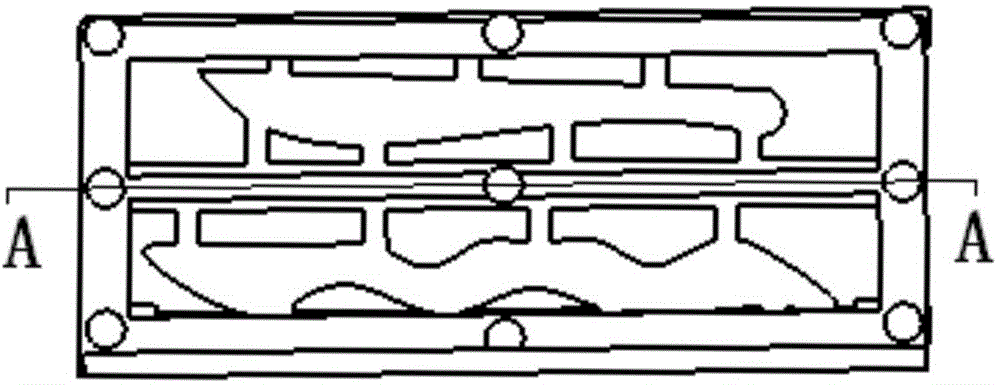

[0019] The embodiment of the measuring tool for the aircraft blade filler of the present invention is composed of a cuboid base 1 and a cuboid frame 2 connected by screws 3 to form the tool body, and its cross-sectional shape is an inverted T shape. The main body of the tooling is connected with three rectangular parallelepiped frame bars 4 and nine screws 5 and nine nuts 6 are used to fit the part under test.

[0020] The point is:

[0021] (1) On the upper surface of the base 1 of the cuboid, there are two threaded through holes with a diameter of 25MM apart from the wide side, and the screw 3 is used to connect the cuboid frame 2 to form the main body of the tooling, which plays a stable role in cooperation with the parts;

[0022] (2) said cuboid frame 2 upper surface has 9 diameters and is 9MM through holes and three auxiliary cuboid frame bars 4, utilizes nine diameters to be 8MM bolts 5 and nine nuts 6 to coordinate the positioning of the parts to be tested;

[0023] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com