Gear shaft processing method and gear shaft clamping tool used in the method

A processing method and a gear shaft technology, which are applied to gear tooth manufacturing devices, components with teeth, metal processing equipment, etc., can solve the problem that the machining accuracy of gear shafts is difficult to meet the design requirements, and it is difficult to eliminate machining accuracy errors that affect gear shafts. Problems such as processing quality, to achieve the effect of not easy radial runout, convenient transportation, and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

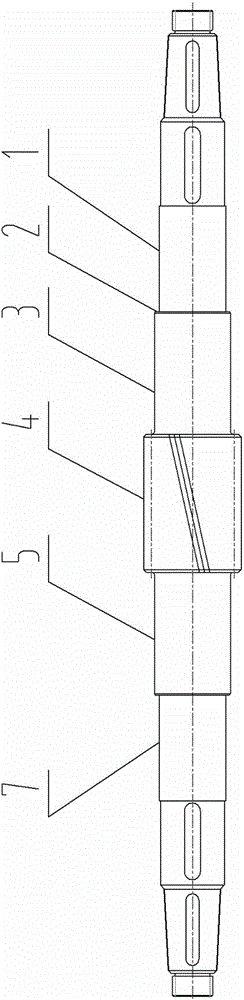

[0021] The structure of the gear shaft to be processed is as follows: figure 1 As shown: including a gear processing section 4 for processing gears, an upper stepped shaft structure 5 and a lower stepped shaft structure 1 are respectively arranged on the upper and lower sides of the gear processing section 4, and both the upper and side stepped shaft structures have The shaft shoulder 2 and the upper and lower sides of the gear processing section 4 on the gear shaft are respectively provided with an upper reference outer circle 7 and a lower reference outer circle 3 coaxial with the gear shaft.

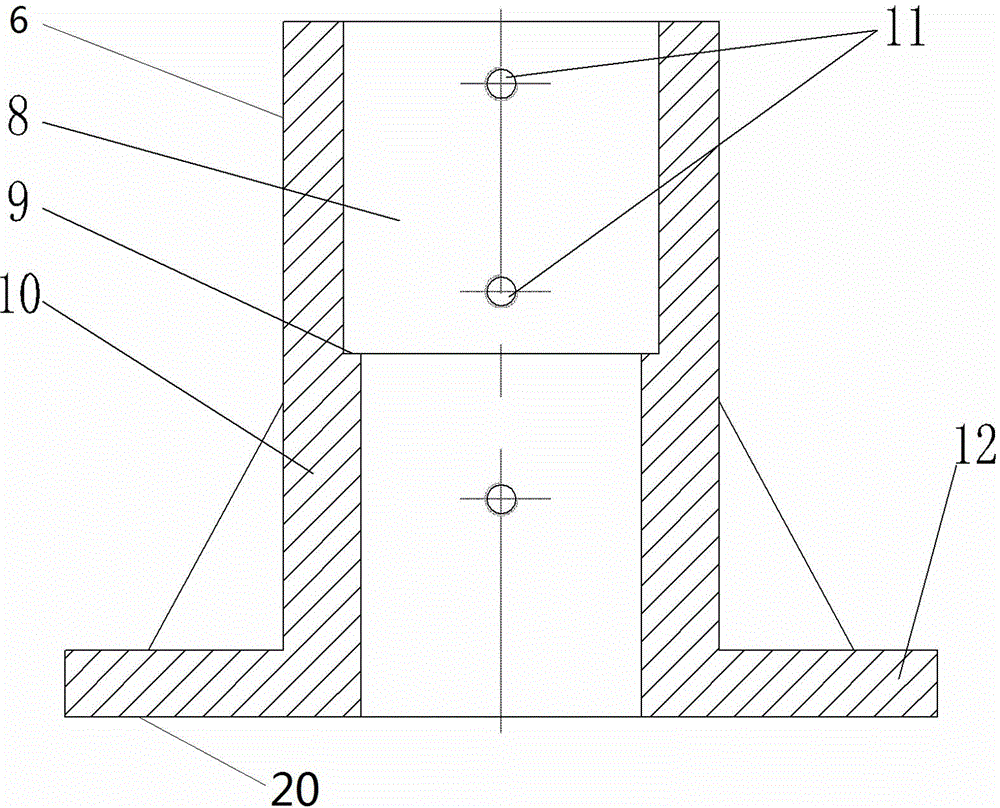

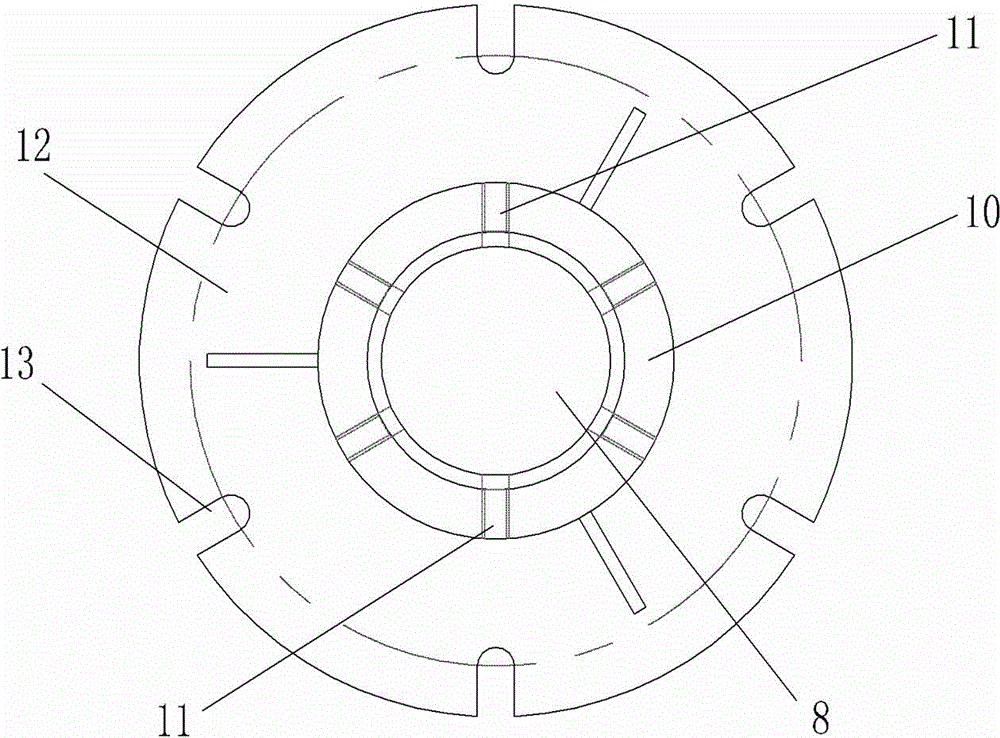

[0022] Examples of gear shaft clamping tooling Figure 1~4 As shown: it includes a stepped bushing with a body 10. The body 10 has a stepped hole 8 that runs through its upper and lower end surfaces. The stepped hole 8 is used for the lower side stepped shaft structure 1 of the corresponding gear shaft to be coaxial from top to bottom when in use. Adapted for insertion, the stepped h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com