Camping device special for coaxiality and centering machining for vertical seat

A technology of coaxiality and equipment, applied in the field of clamping fixtures, can solve the problems of high technical level requirements of staff, affecting processing accuracy, poor clamping firmness, etc., to achieve good centering effect, improve processing accuracy, and fix firmly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings; it should be noted that this embodiment is descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

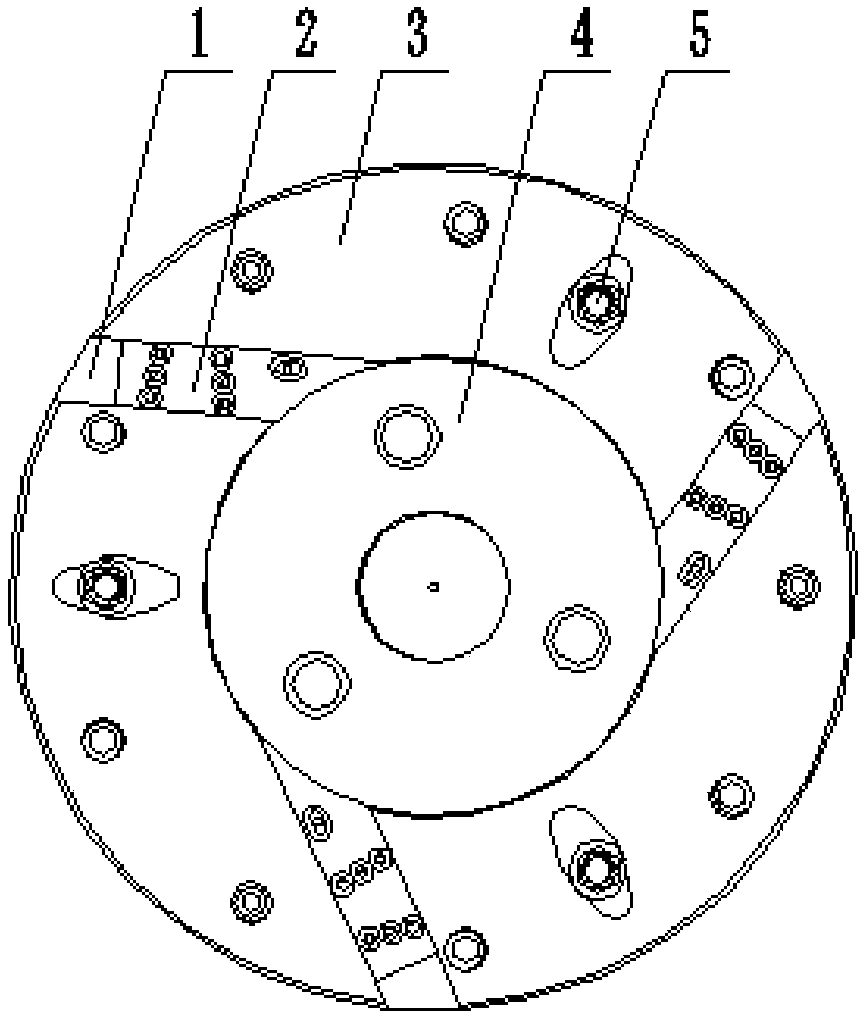

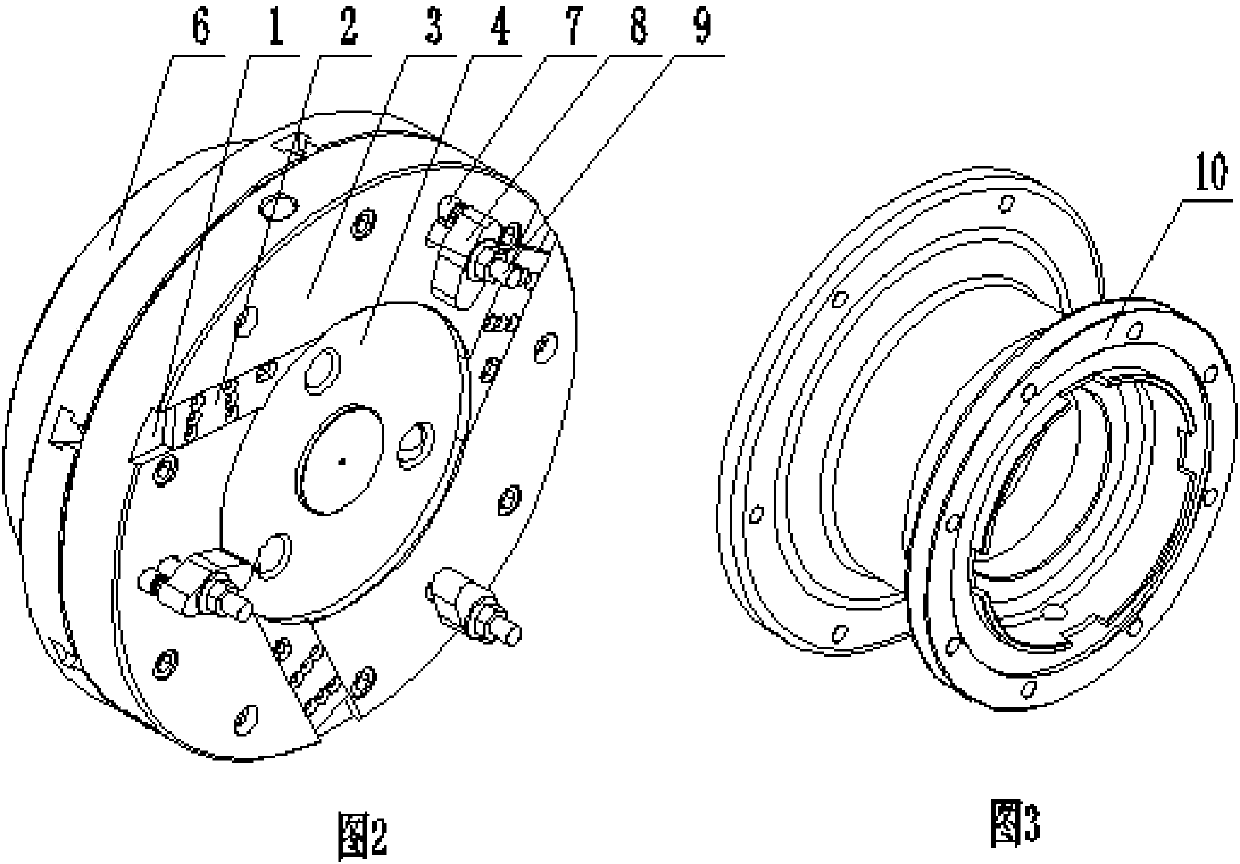

[0017] A special clamping device for vertical seat processing coaxiality centering, including a base 3 and a hydraulic pressure plate assembly 5. The base is a disc shape, and a chuck 6 is coaxially installed on the back of the base to facilitate the installation of the device on the machine tool . A circular positioning groove 4 is coaxially formed at the axis of the front of the base, and three hydraulic pressure plate components are uniformly arranged on the base outside the circular positioning groove, and the three hydraulic pressure plate components are uniformly arranged in the circumferential direction. Each hydraulic pressure plate assembly described is composed of a pressure plate 8 and a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com