Self-testing device and self-testing method of power quality monitoring device

A power quality monitoring and self-testing technology, applied in measuring devices, measuring electrical variables, instruments, etc., can solve problems such as low test work efficiency, test process dependence on personal ability, long test cycle, etc., to achieve high-efficiency automatic inspection, The effect of simplifying normative data forms and reducing personnel requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

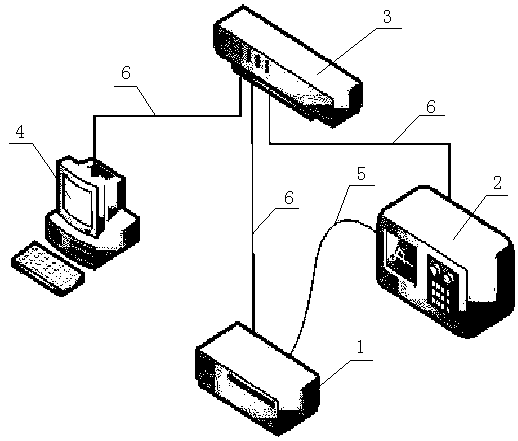

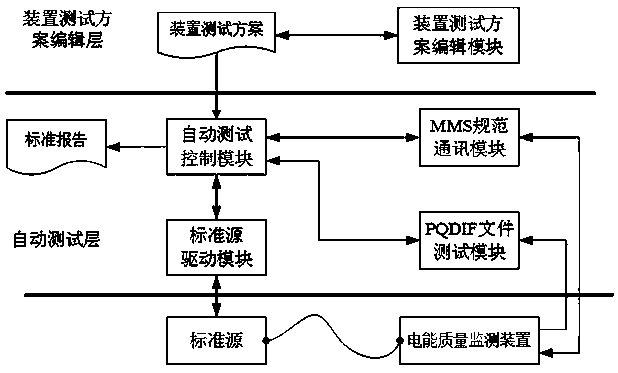

[0027] Embodiment 1, the power quality monitoring device self-test device includes a standard source 1, a power quality monitoring device 2, a switch 3 and a test terminal 4; the standard source 1 and the power quality monitoring device 2 are connected by a test line 5, and the switch 3 is connected to the test terminal 4. The terminal 4, the standard source 1 and the power quality monitoring device 2 are respectively connected through a network cable 6; the test terminal 4 includes an automatic test layer and a device tester editing layer.

Embodiment 2

[0028] Embodiment 2, as the optimization of Embodiment 1, the automatic test layer includes an automatic test control module and a standard source driver module connected to the automatic test control module, an MMS standard communication module, a PQDIF file test module and a standard report module; the device tester edits The layer includes a device test plan editing module and a device test plan connecting the device test plan editing module.

Embodiment 3

[0029] Embodiment 3, as an optimization of Embodiment 2, the device test plan editing module includes a standard test template and a report template of the power quality device under test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com