Manufacturing technique for split type carbon powder box

A production process and toner cartridge technology, applied in the field of split toner cartridge production process, can solve problems such as low production efficiency, complicated process, and environmental pollution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

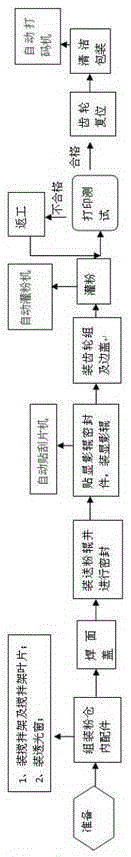

[0022] Such as figure 1 As shown, in this embodiment, the split toner cartridge production process includes the following steps:

[0023] (1) Assemble the accessories in the powder bin, including installing the mixing frame, mixing blades and light-transmitting windows;

[0024] (2) Welding cover;

[0025] (3) Install the powder feeding roller and seal it;

[0026] (4) Paste the developing roller seal and install the developing roller by the automatic scraping machine;

[0027] (5) Install the gear set and side cover;

[0028] (6) The powder filling is completed by the automatic powder filling machine.

[0029] (7) Printing test, if the printing test is qualified, go to step (8), if the printing test fails, rework;

[0030] (8) Gear reset;

[0031] (9) Clean the package and use an automatic coding machine for coding.

[0032] After the above process, the following effects can be achieved:

[0033] 1. Greatly improved production efficiency;

[0034] 2. Reduce productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com