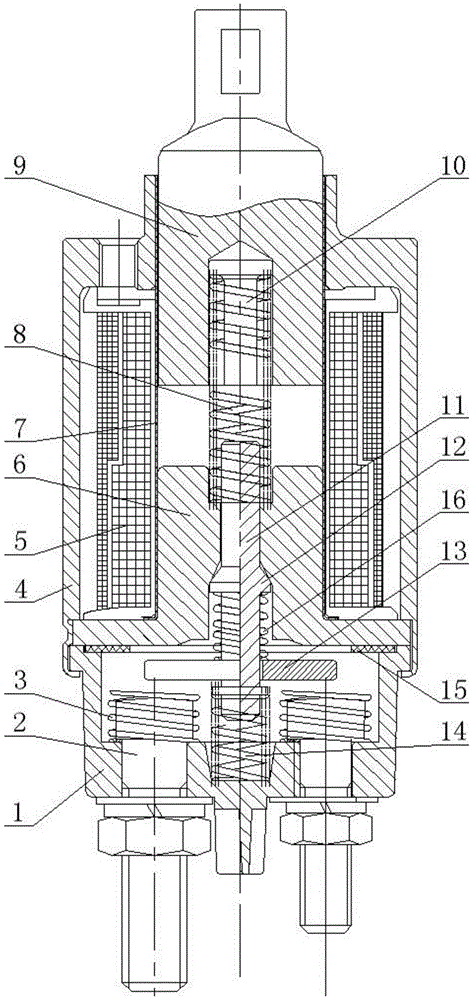

Anti-icing starter solenoid switch with coil spring contacts

A helical spring and electromagnetic switch technology, applied in electromagnetic relays, electromagnetic relay details, circuits, etc., can solve the problems of starters not starting normally, heat loss, etc., and achieve the effect of safe and reliable use and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] As shown in the figure, the anti-icing starter electromagnetic switch with helical spring contact includes a casing 4, an insulating seat 1 arranged at the bottom of the casing 4, two static contacts 2 arranged in the insulating seat 1, fixed on The ring-shaped support limit seat 6 above the insulating seat 1, the movable contact rod 11 pierced in the center of the ring-shaped support limit seat 6, the bottom end of the movable contact rod 11 and the angle between the movable contact rod 11 and the movable contact rod 11 are 90 degrees. The moving contact piece 13, the return spring 14 arranged between the lower end of the moving contact rod 11 and the bottom surface of the insulating seat 1, the sleeve 7 set on the outer periphery of the upper part of the annular support limit seat 6, and the sleeve 7 formed by the casing 4 The electromagnetic coil 5 in the annular space is arranged in the sleeve 7 and is supported by the supporting spring 8 on the moving iron core 9 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com