Screw tightening shaft device capable of rotating and conducting reciprocating linear movement

A reciprocating straight line and tightening shaft technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting product assembly quality, screw missing and incorrect assembly, etc., to improve product assembly quality and production efficiency, eliminate Influence of product quality, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

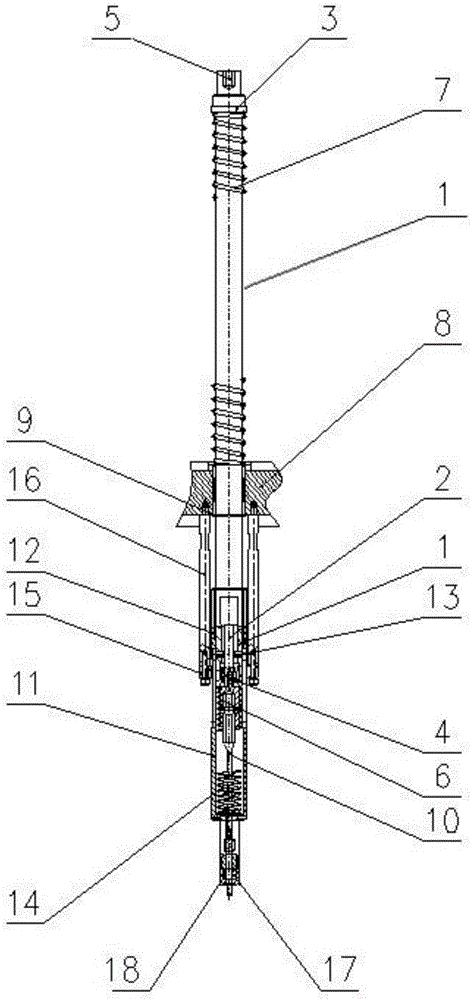

[0019] Such as figure 1 As shown, a screw tightening shaft device capable of rotating and reciprocating linear movement, which includes a rotating and reciprocating linear movement mechanism, a screw distance limiting mechanism, and a screw grasping mechanism.

[0020] The rotating and reciprocating linear movement mechanism includes a guide tube 1, a rotating shaft 2, a first oil-free bushing 3, a second oil-free bushing 4, a shaft end torque transmission member 5, a screwdriver fixing member 6, and a first compression spring 7. Turn plate 8 and screwdriver 10. The guide pipe 1 is installed in the rotating plate 8 through the first oil-free bushing 3, the second oil-free bushing 4 and the first compression spring 7 at both ends, and the rotating shaft 2 passes through the first oil-free bushing at both ends of the guide pipe 1. The oil bushing 3 and the second oil-free bushing 4 are installed in the guide pipe 1, the shaft end torque transmission part 5 and the screwdriver f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com