An automatic measuring track inspection car

An automatic measurement and rail inspection vehicle technology, applied in the field of rail inspection vehicles, can solve the problems of complex operation, high labor intensity, large volume, etc., and achieve the effect of accurate positioning and long data transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

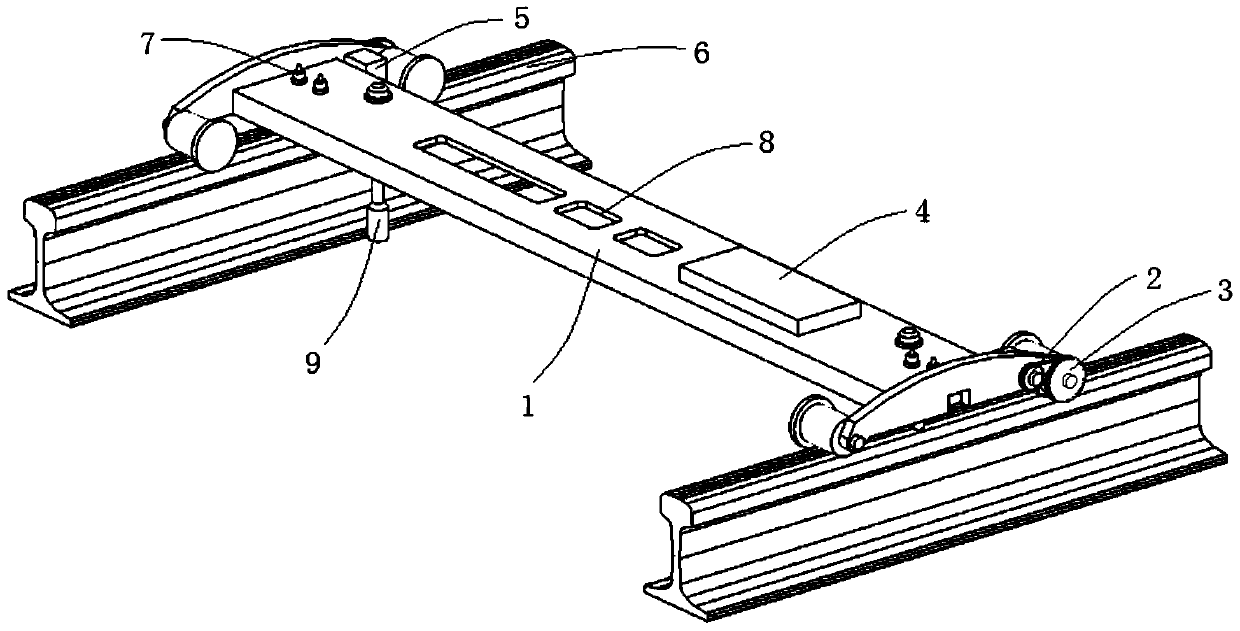

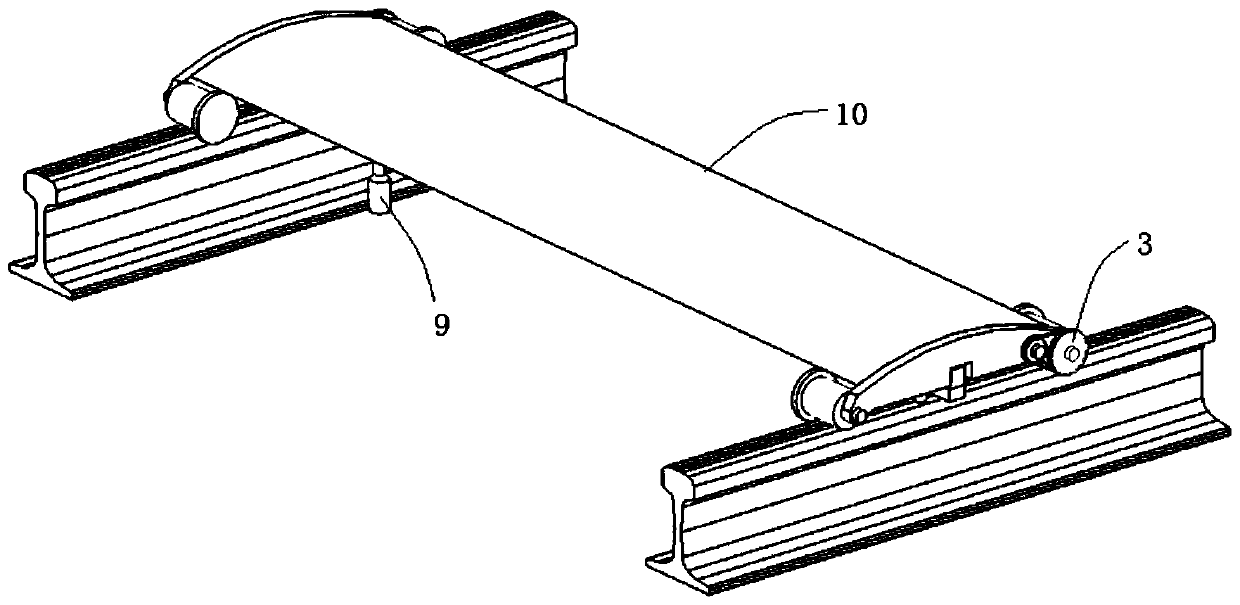

[0021] Such as figure 1 , figure 2 Shown is the structural schematic diagram of the automatic measuring track inspection vehicle of the specific embodiment of the present invention, including the vehicle frame body 1, in addition, it also includes:

[0022] The stepper motor 2 arranged at both ends of the frame body 1, the stepper motor 2 drives the frame body 1 through the wheels 3 connected thereto;

[0023] control processor 4;

[0024] A gauge ruler arranged at the bottom of the frame body 1, the gauge gauge is connected to the control processor through a data line and / or a wireless communication module to transmit detection data;

[0025] The inkjet printer 5 arranged on the vehicle frame body 1 is used for inkjet marking on the rail 6; preferably, the control processor 4 compares the measured data of the current measurement point with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com