Safe yarn guide transverse rod

A yarn guide bar and cross bar technology, applied in spinning machine, open end spinning machine, continuous winding spinning machine, etc., can solve the problems of image yarn quality, poor yarn quality, yarn friction, etc. , to achieve the effect of flexible application, improving production efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

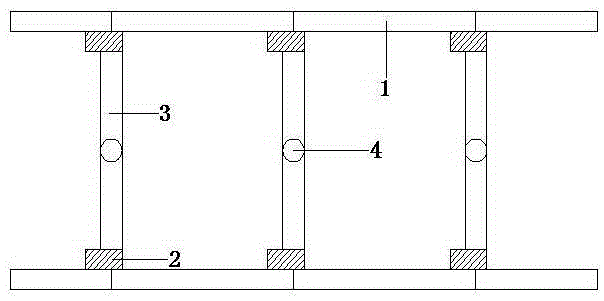

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes two yarn guide rods 1 correspondingly erected in parallel, and the two yarn guide rods 1 are provided with several corresponding fixing seats 2, and a cross bar 3 is erected between the two corresponding fixing seats 2, and the cross bar 3 The fixing bases 2 at both ends are located on the same side of the crossbar 3; the crossbar 3 is erected on the column 4 in the middle; the yarn guide rod 1 is composed of several shortened tubes connected back and forth, and the inner diameter of one end of the short tube is connected with the other. The outer diameter of one end is the same.

[0015] A number of short rods are connected front and back to form a yarn guide rod 1, and two yarn guide rods 1 are erected in parallel, and a plurality of sets of fixing seats 2 are correspondingly arranged on the two yarn guide rods 1, and a horizontal bar 3 is installed through the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com