Tool for removing tripmine quickly

A fast and tool-based technology, applied in the direction of defense devices and offensive equipment, can solve the problems of danger to mine-clearing personnel, shortened mine-clearing distance, and low efficiency, and achieve the effect of reducing the difficulty of recovery and increasing the mine-clearing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

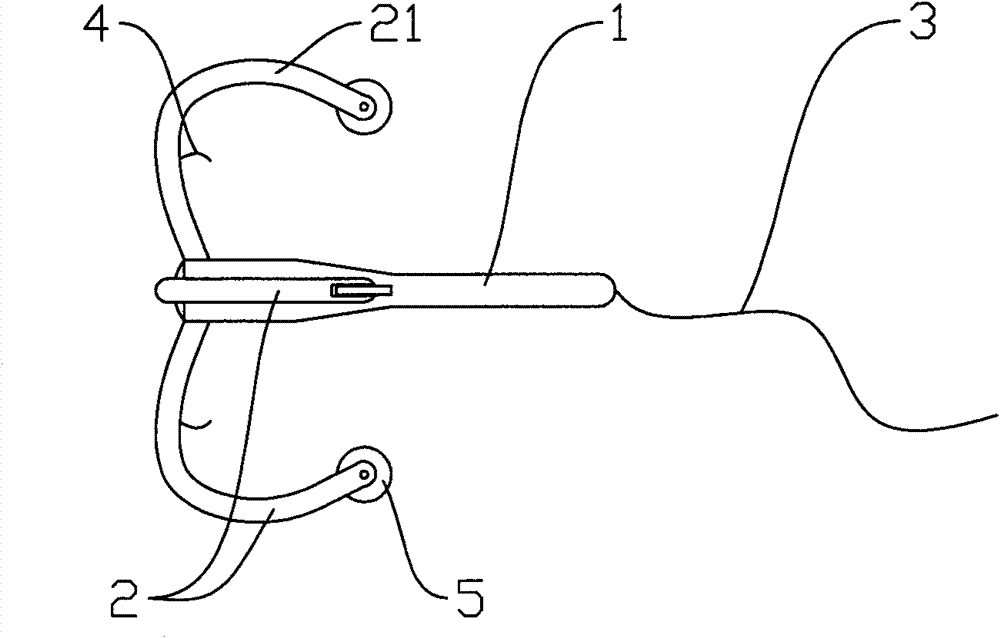

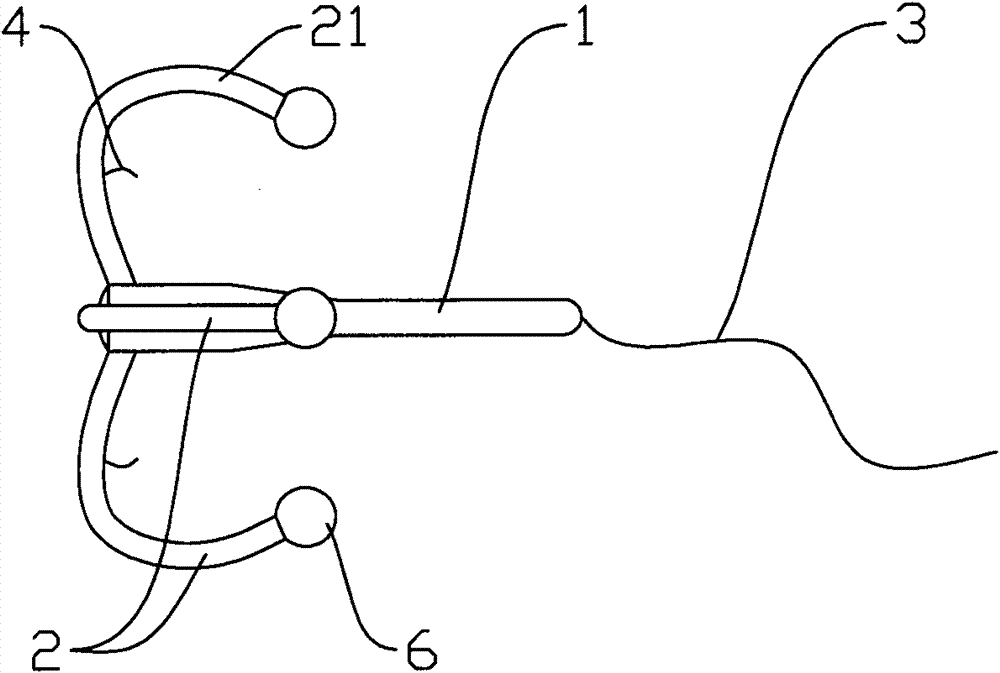

[0015] Such as figure 2 and 3 A structural schematic diagram of an embodiment of the present invention is shown, a quick mine removal tool, including an anchor rod 1, the front end of the anchor rod is a round blunt surface, and at least three backward-curved anchor hooks are arranged at the front end of the anchor rod 2. The present invention is provided with four anchor hooks, a pull rope 3 is provided at the rear end of the anchor rod, and a barb 4 for hooking a lightning trip wire is provided on the side of the middle part of the anchor hook corresponding to the rear end of the anchor rod, and the tail end of the anchor hook A smooth structure is provided to prevent the anchor hook from inserting into the soil or hooking the shrubs, and the smooth structure is a pulley 5 connected to the tail end of the anchor hook.

[0016] In the above-mentioned embodiment, the rear end of the anchor hook is set as the hook portion bent toward the anchor rod, and the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com