Energy-saving automatic speed control system of light motorcycle

A light motorcycle, automatic transmission technology, applied in bicycle gear transmission mechanism, bicycle accessories, transportation and packaging, etc., can solve the problems that the fuel-saving potential of the engine cannot be fully utilized, the energy-saving requirements cannot be met, and the driver's labor intensity is high. Achieve good cushioning, compact structure, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

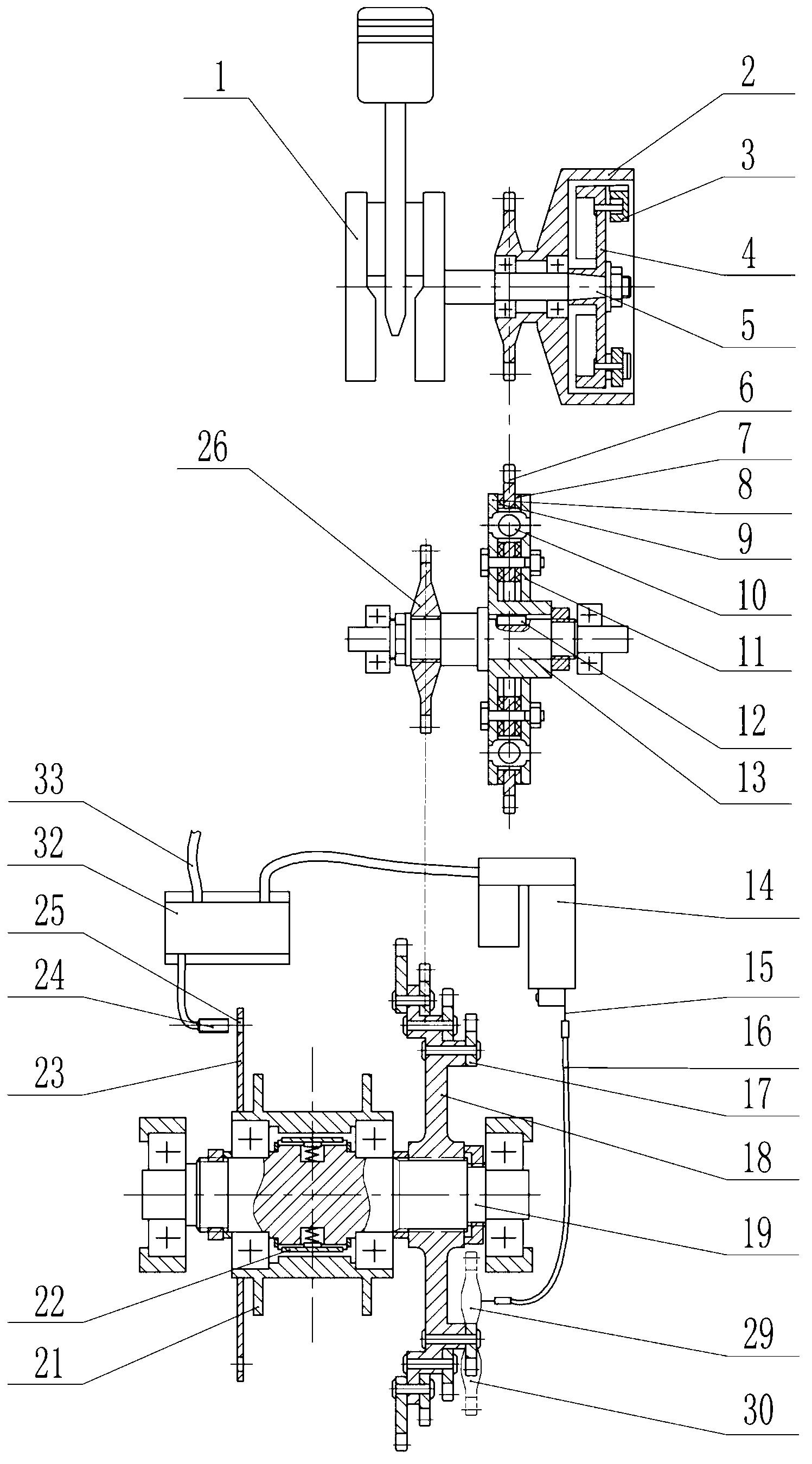

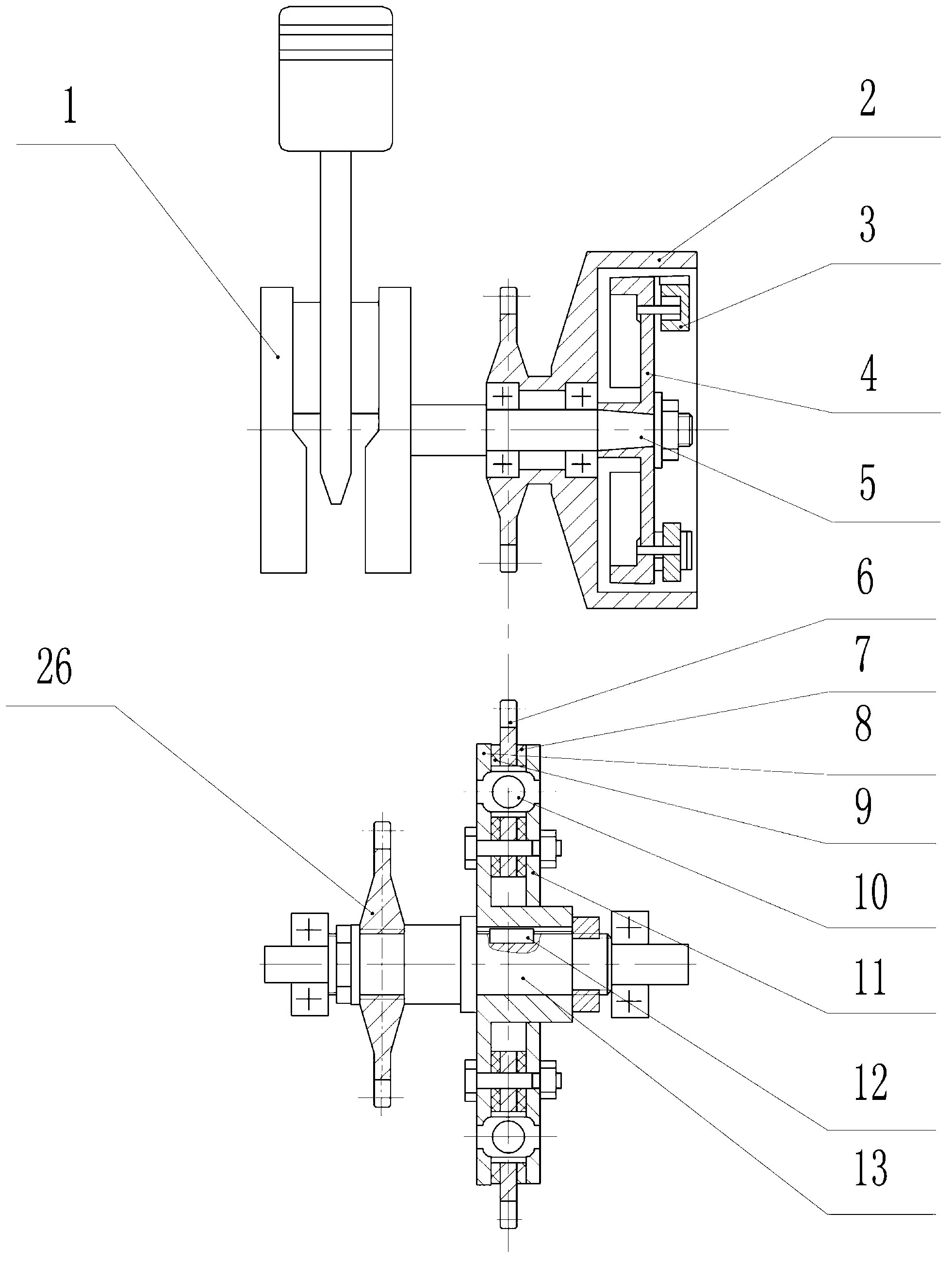

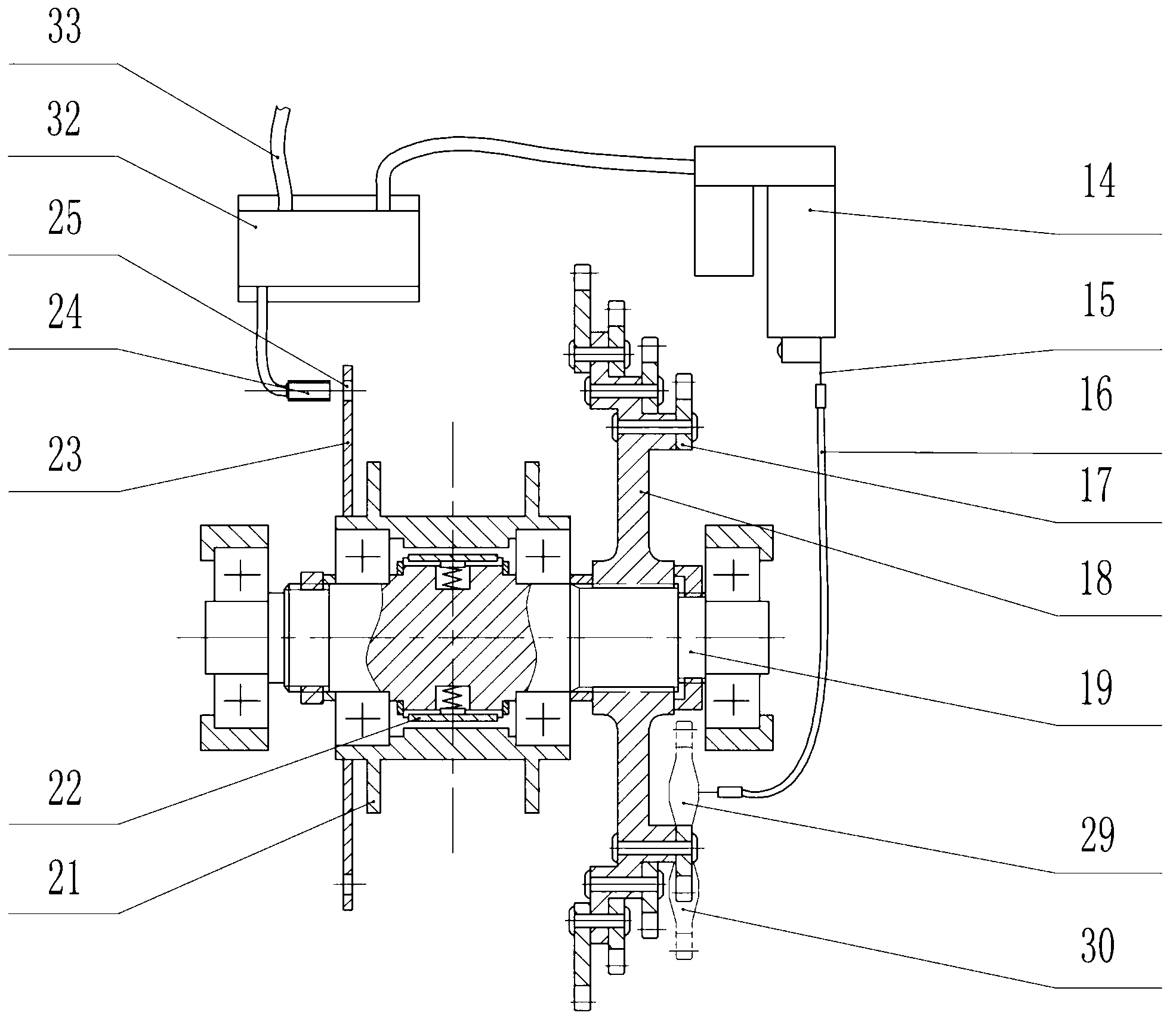

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

[0029] refer to figure 1 , Figure 4 and Figure 5 , The light motorcycle energy-saving automatic transmission system of the present invention is composed of a centrifugal flying block clutch, a primary reduction device, a secondary reduction device, an automatic transmission control device, and a rear axle assembly.

[0030] The power of the engine 1 is transmitted to the centrifugal flyweight clutch through the crankshaft output shaft 5, and then transmitted to the torsional shock absorber through the primary chain 27, and then the intermediate shaft 13 and the intermediate sprocket 26 transmit the power to the transmission chain through the secondary chain 28 The wheel set 17 drives the rear axle 19, and finally the power is output to the rear hub 21 through the overrunning clutch to drive the motorcycle forward. The present invention adopts a two-stage chain transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com