A Surface Conformal Method for Aircraft Formation Lights

A surface and aircraft technology, applied in the field of formation lights, can solve the problem of large interlayer stress of epoxy glass cloth, and achieve the effect of providing anti-vibration performance and temperature shock performance, accurate curved surface forming, and high brightness uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

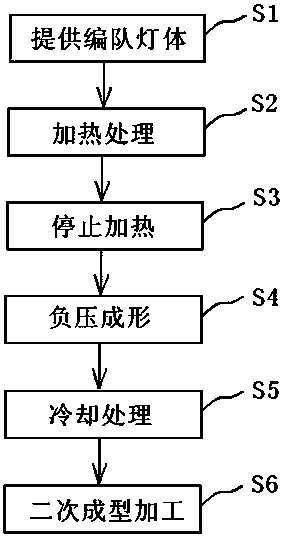

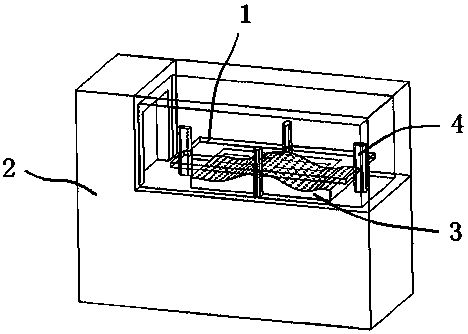

[0036] see Figures 1 to 4 , what is shown in the figure is a surface conformal method for aircraft formation lights, and the following steps are performed in sequence,

[0037] Step S1, providing formation lamp bodies 1 .

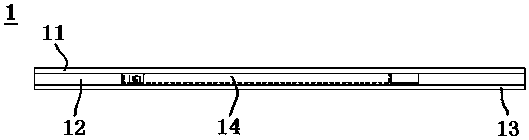

[0038] The formation lamp body 1 includes a lamp body shell and a curved surface light source 14 .

[0039] The lamp body shell has a panel 11 , a middle panel 12 and a bottom panel 13 which are sequentially arranged from top to bottom. The face plate 11, the middle plate 12 and the bottom plate 13 are respectively made of glass fiber reinforced polycarbonate plates of corresponding thickness. The final quality of surface forming is closely related to the thickness, thickness ratio and material selection of each plate. In this embodiment, the thicknesses of the panel 11, the middle plate 12, and the bottom plate 13 are 1mm, 2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com