Detonation gas rock breaking experimental device and method

A technology of explosive gas and experimental equipment, which is applied in the field of explosive gas rock-breaking experimental equipment, can solve the problems of low loading rate and inability to accurately reflect the explosive gas load waveform, and achieve secondary damage prevention, simple structure, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

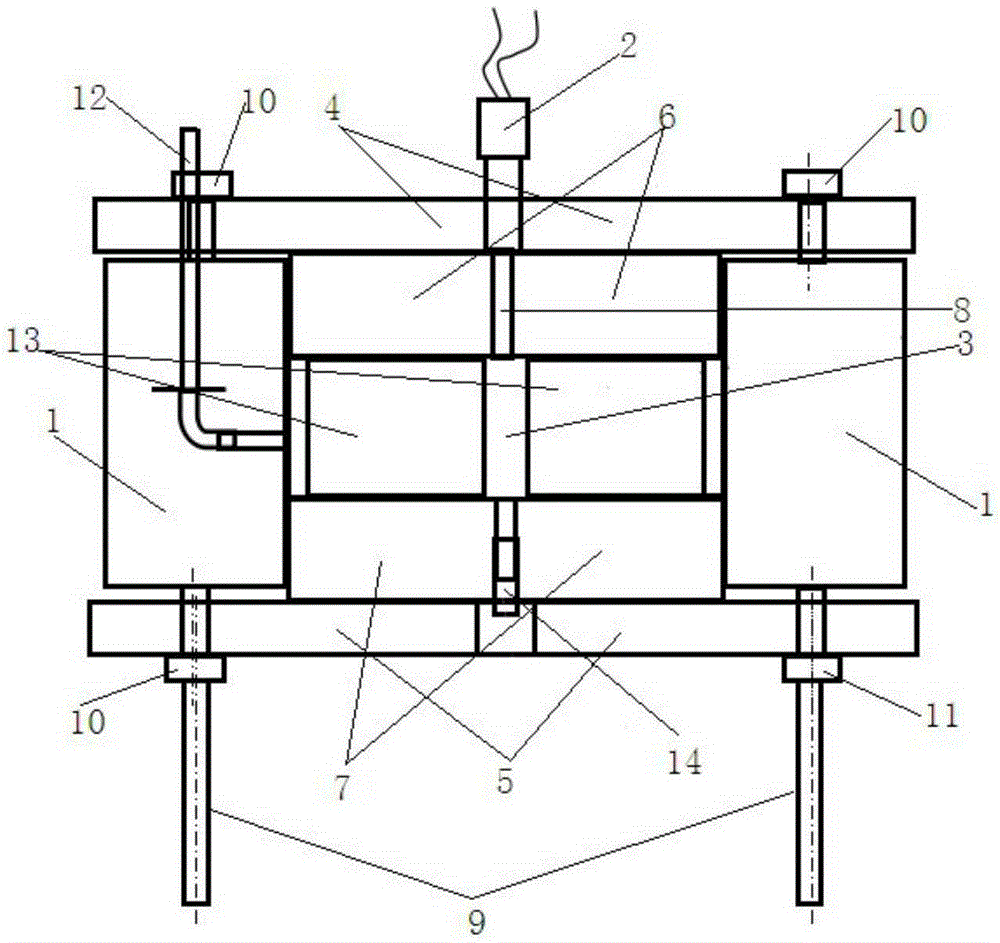

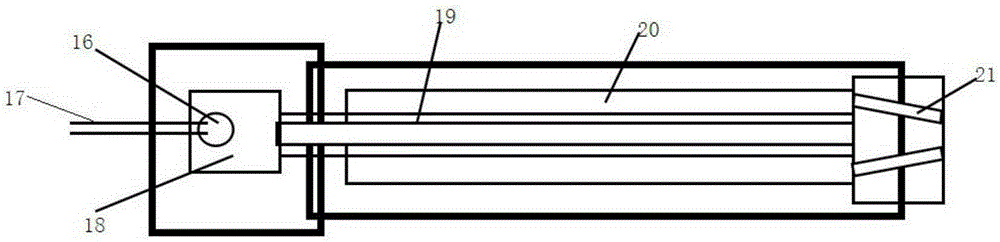

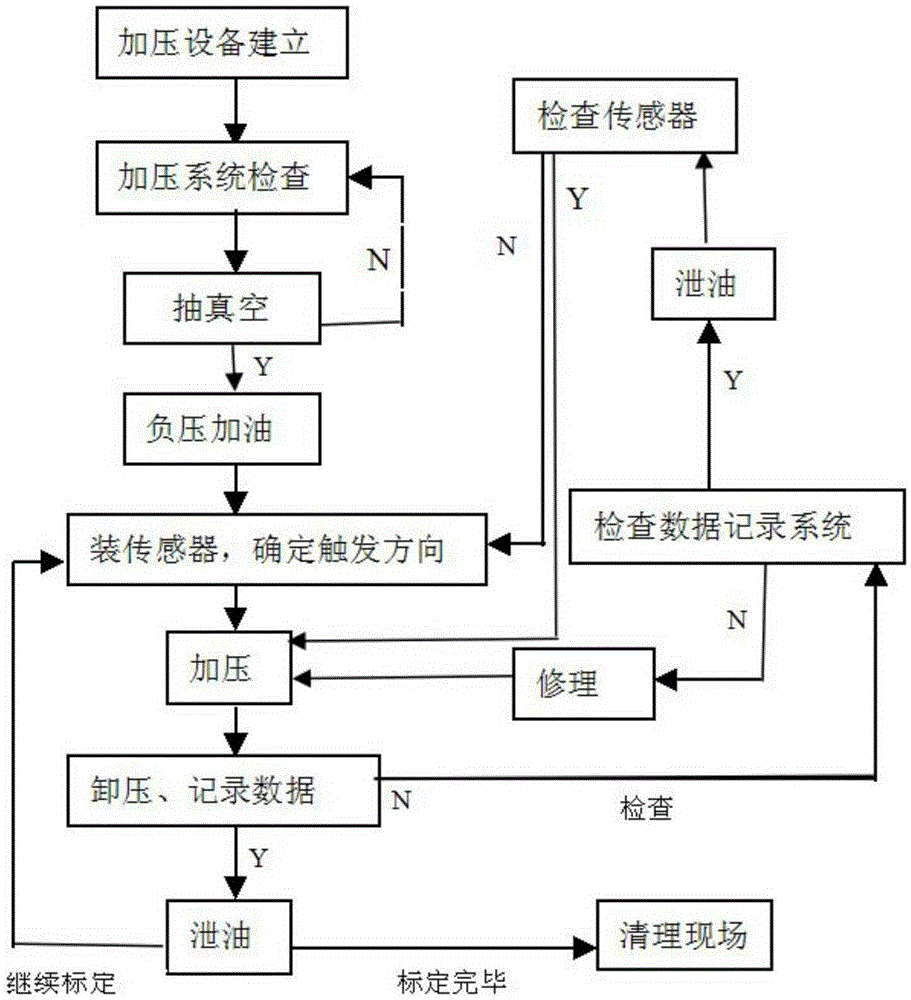

[0026] The explosive gas rock-breaking experimental device described in this embodiment includes a cylinder body 1, an ignition device 2, a sample center hole 3, an upper cover plate 4, a lower cover plate 5, an upper piston 6, a lower piston 7, and an upper piston center hole 8 , support rod 9, compression bolt 10, pressure measuring bolt 11, water injection hole 12, sample 13, pressure measuring sensor 14 and lower piston center hole 15; There are two upper cover plates 4, and an upper piston 6 is installed under each upper cover plate 4, and an upper piston center hole 8 is left between the two upper pistons 6; two lower cover plates are arranged at the lower end of the cylinder body 1 5. A lower piston 7 is installed above each lower cover plate 5, and a lower piston center hole 15 is left between the two lower pistons 7; a sample 13 is placed between the upper piston 6 and the lower piston 7, and the sample The two ends of 13 are pasted with 4mm thick double-sided tape an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com