Test device and test method for oil leakage detector

A technology for oil leakage and test device, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problem of inability to go to the industrial site for detection, and achieve the effects of good convenience, convenient experimentation, and easy location.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

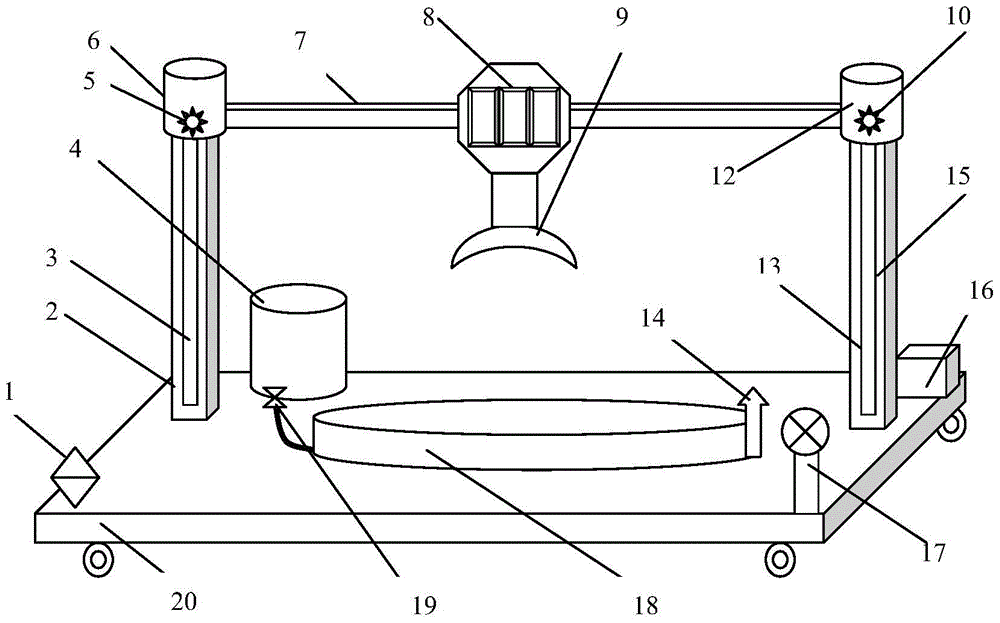

[0042] refer to Figure 1~3 As shown, the test device of the oil leakage detector of the present invention includes a mobile base 20, a test frame and an oil tank 18, and the test frame is placed above the mobile base 20; the oil tank 18 is placed on the mobile base 20, and the oil tank 18 A liquid level altimeter 14 is provided.

[0043] Wherein, the test stand comprises two left columns 2 and a right column 15 fixed on the mobile base 20, and the left column 2 and the right column 15 are respectively covered with a left slider 6 and a right slider 12, which can be moved along the left column 2. , the right column 15 moves up and down; a horizontal guide rod 7 is horizontally set between the left slider 6 and the right slider 12, and the horizontal guide rod 7 is placed above the oil tank 18; The test meter 8 of concentration can slide horizontally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com