Press-fitting inner supporting device for amorphous alloy oil-immersed transformer coil

An oil-immersed transformer and amorphous alloy technology, applied in coil manufacturing and other directions, can solve problems such as the backlog of molds in the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

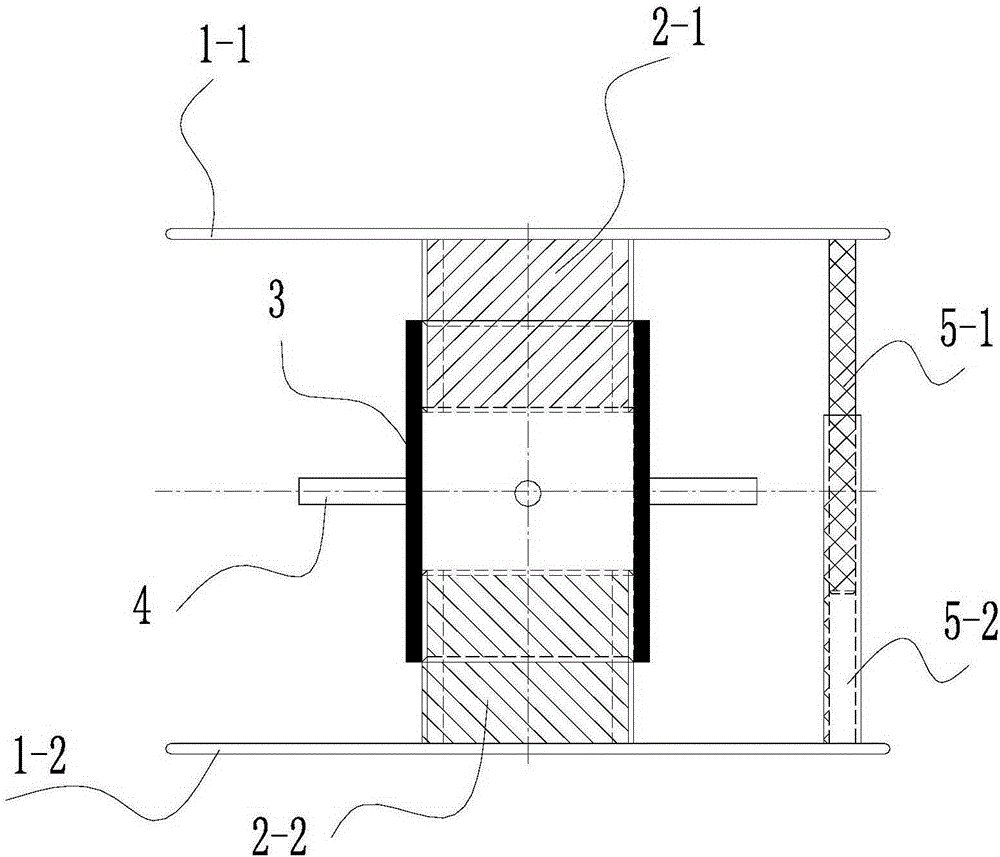

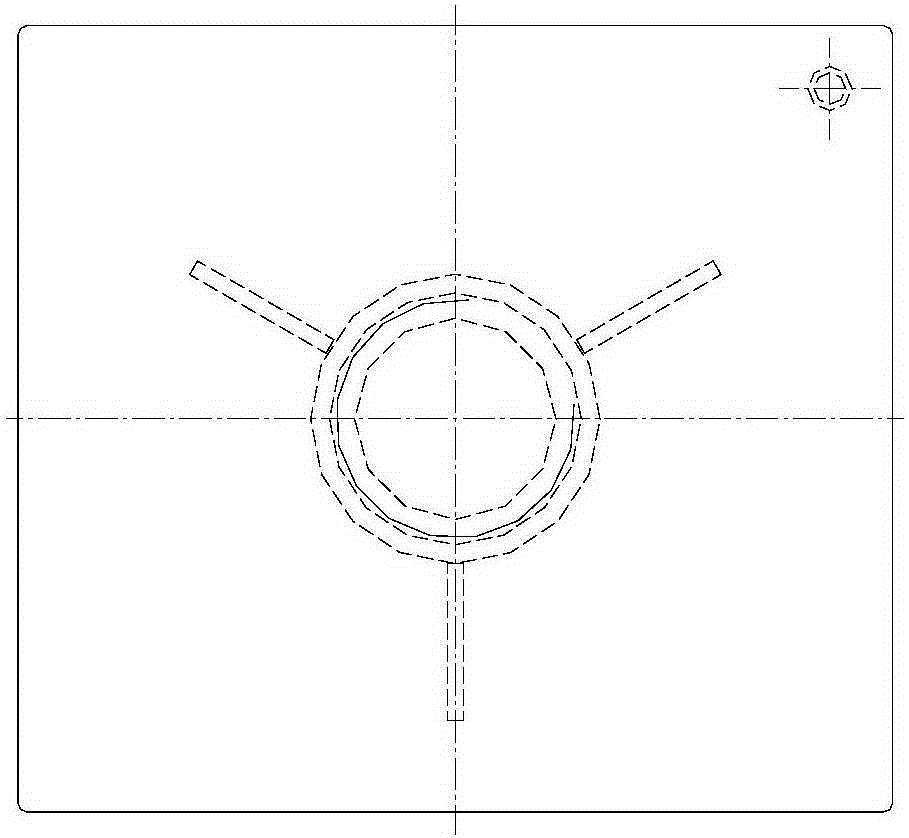

[0014] see figure 1 with figure 2 , a press-fit inner supporter for an amorphous alloy oil-immersed transformer coil, including four parts: an end plate, an externally threaded column, an internally threaded tube 3, and a positioning column; wherein: the end plate includes an upper end plate 1- 1 and the lower end plate 1-2; the externally threaded column includes a lower externally threaded column 2-1 welded to the lower surface of the upper end plate 1-1, and an upper externally threaded column welded to the upper surface of the lower end plate 1-2 2-2; the lower external thread column 2-1 and the upper external thread column 2-2 are connected through the internal thread pipe 3; the positioning column is used to align the upper end plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com