A high-voltage capacitor with a plug-in bipolar outlet structure

A high-voltage capacitor, plug-in technology, used in the field of capacitor manufacturing and application, can solve the problems of gas or liquid leakage, inability to carry out operations, waste of surrounding environment, etc., to improve reliability, save manpower and equipment occupation, and reduce power outages. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

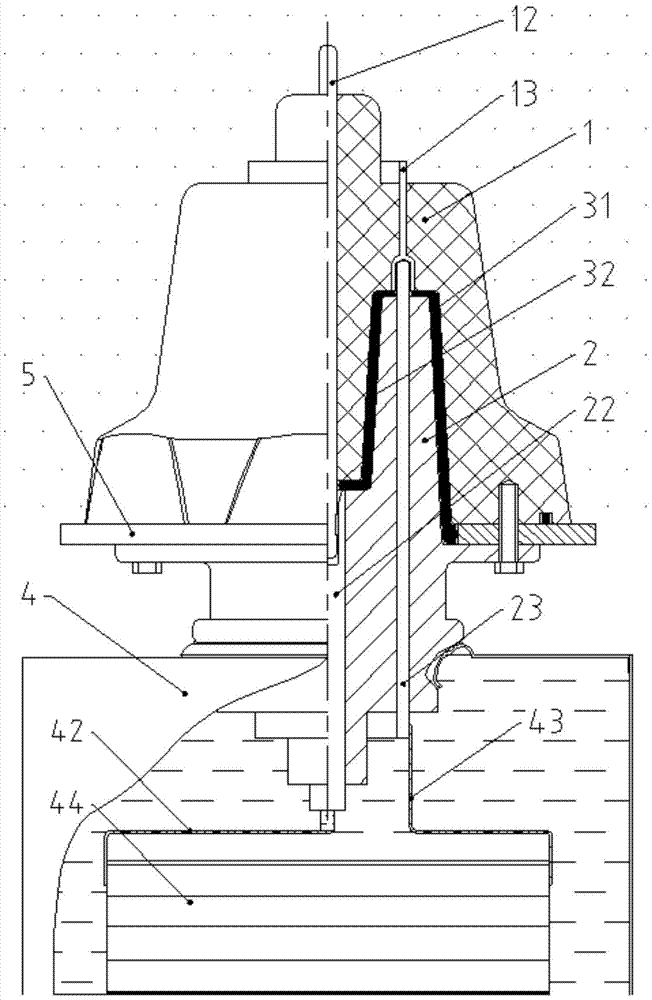

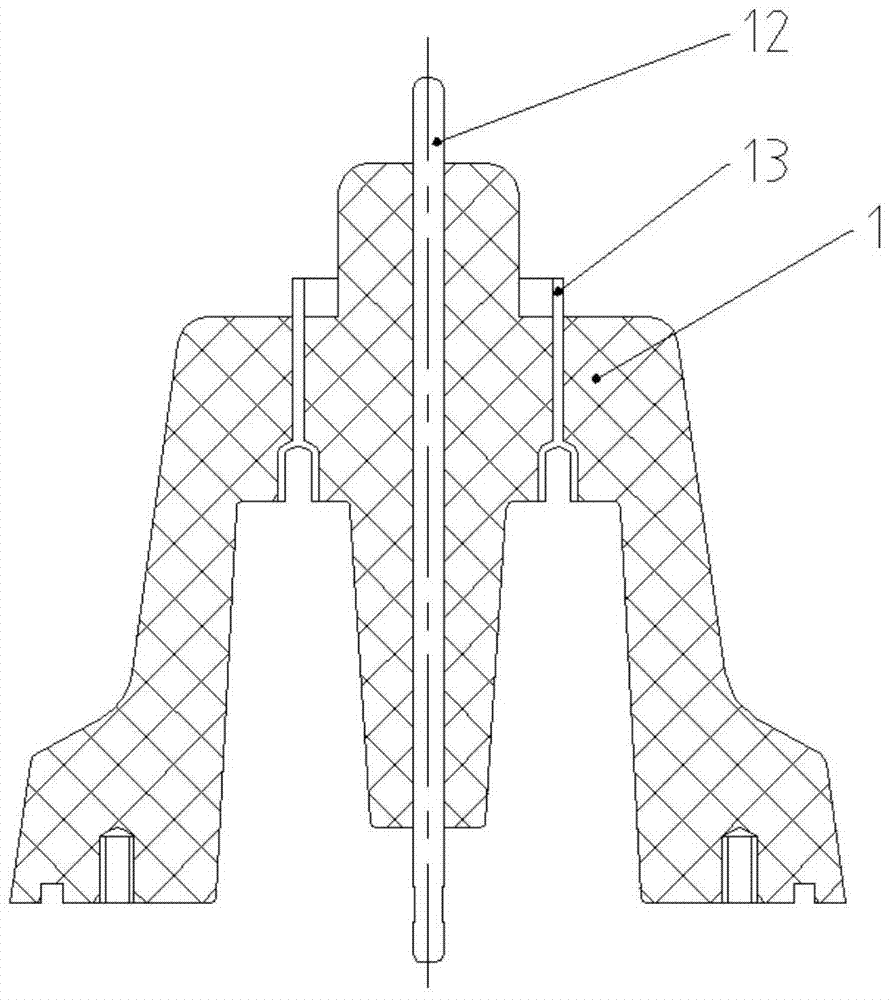

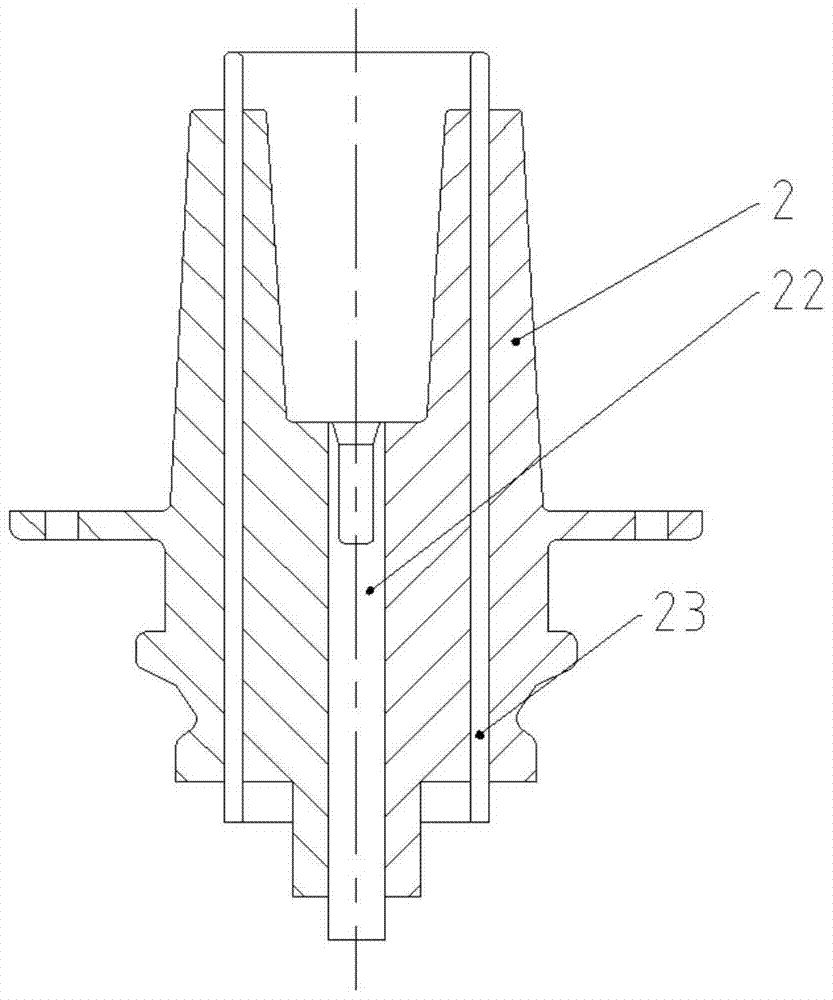

[0024] The present invention is a high-voltage capacitor with a plug-in bipolar outlet structure, the structure described in this preferred example, such as figure 1 As shown, it includes an inner cone socket 1, an outlet bushing 2 and a capacitor body 4, and only one outlet bushing 2 is arranged on the top of the capacitor body 4; the outlet bushing 2 has a U-shaped ring structure in an axial section, It includes a casing inner electrode 22 located in the center and a casing outer electrode 23 arranged on a U-shaped annular boss; the inner cone socket 1 has a ring structure with an M-shaped axial section, and an obvious The protrusion forms an annular groove with the outer wall; the annular boss of the U-shaped structure of the outlet sleeve 2 can extend into the annular groove of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com