An anti-static protection board for electric power maintenance

An electric power maintenance and anti-static technology, applied in the field of electric power maintenance anti-static protection boards, can solve problems such as electric shock accidents and step voltages, and achieve the effects of avoiding potential safety hazards, improving fire performance and enhancing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

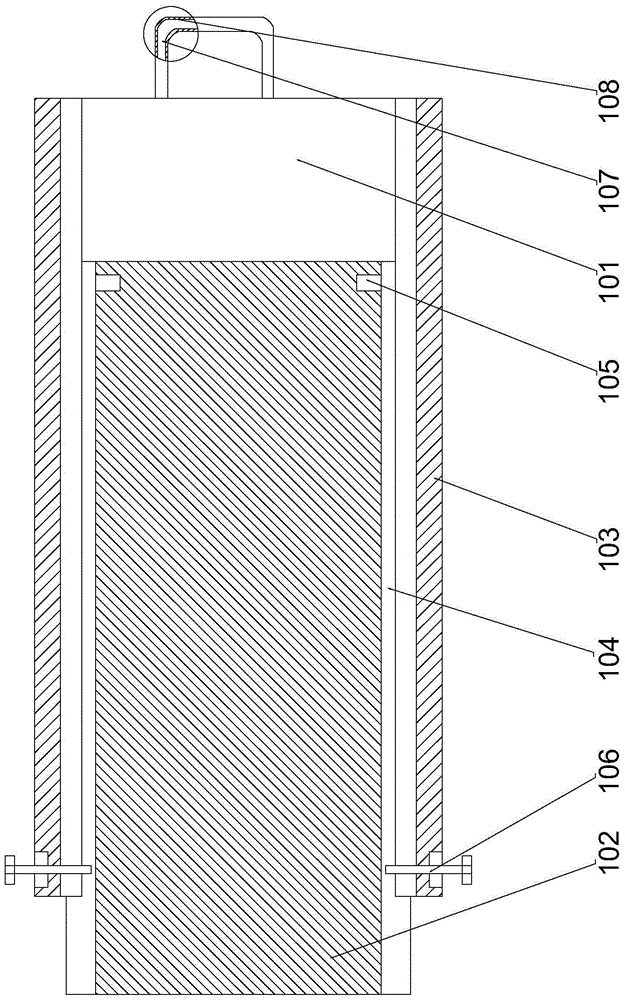

[0024] like figure 1 As shown, an anti-static protection board for electric power maintenance includes an outer board body 101 and an inner board body 102. The upper and lower ends of the outer board body 101 are provided with bent parts 103. A chute 104 is provided on the upper and lower end surfaces of the laminate body 102, and one end of the bent portion 103 is snapped into the chute 104, and a blind hole 105 is provided on one end surface of the chute 104, and The upper end surface of the bending portion 103 is provided with a threaded hole, and a bolt 106 is arranged in the threaded hole, and the bolt passes through the threaded hole and is embedded in the blind hole 105. A rubber layer 106 is provided on the outer end surface of the bending portion 103, and the rubber layer is bonded to the bending portion 103 by a fireproof adhesive, and the rubber layer 106 is rubber mixed with white carbon It is made of black and fire-proof adhesive, and the surface of the outer pla...

Embodiment 2

[0027] In order to improve the safety performance, on the basis of Embodiment 1, in this embodiment, preferably, both the outer layer body 101 and the inner layer body 102 are covered with insulating rubber.

[0028] In order to facilitate grasping, in this embodiment, preferably, a handrail 107 is provided on the side wall of the outer layer body 101, an insulating layer 108 is provided on the said handrail 107, and an insulating layer 108 is provided on the said handrail 107. The grounding device 109 of the insulating layer 108 is provided on it. By setting the insulating layer, it is possible to avoid electric shock when holding the handrail.

[0029] In order to avoid denaturation and aging of the insulating layer under the action of light, in this embodiment, preferably, the surface of the insulating layer 108 is coated with cured titanium dioxide colloid.

[0030] In order to improve the fireproof performance, in this embodiment, preferably, the cured titanium dioxide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com