Pinion and rack drilling rig derrick structure and installation method thereof

A technology of rack and pinion and derrick, which is applied in the direction of drilling equipment, earthwork drilling and support devices, etc., which can solve the problems of unbalanced force of rack and pinion, affecting the drilling force of the drilling rig, and affecting the drilling efficiency, so as to ensure the stability , Reduce weight, improve stability and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

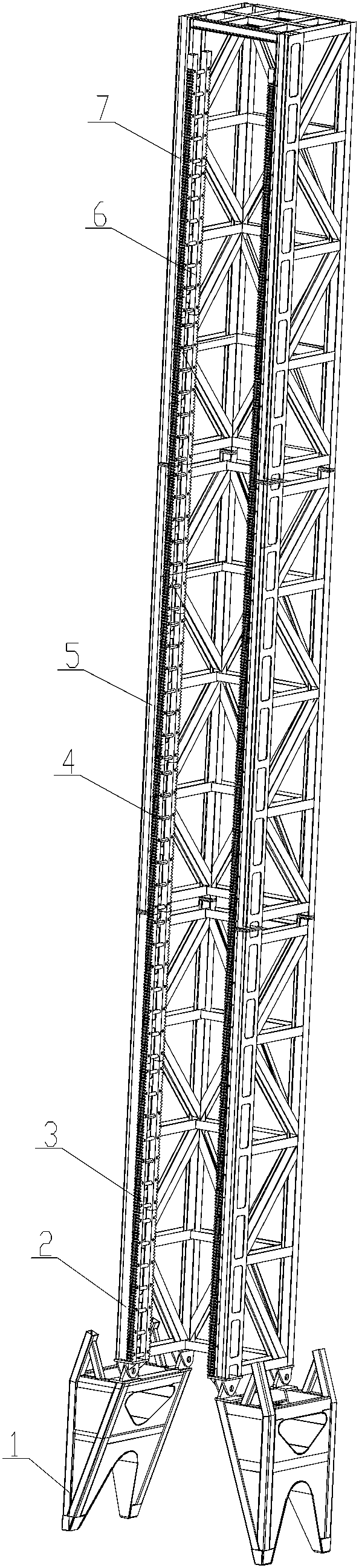

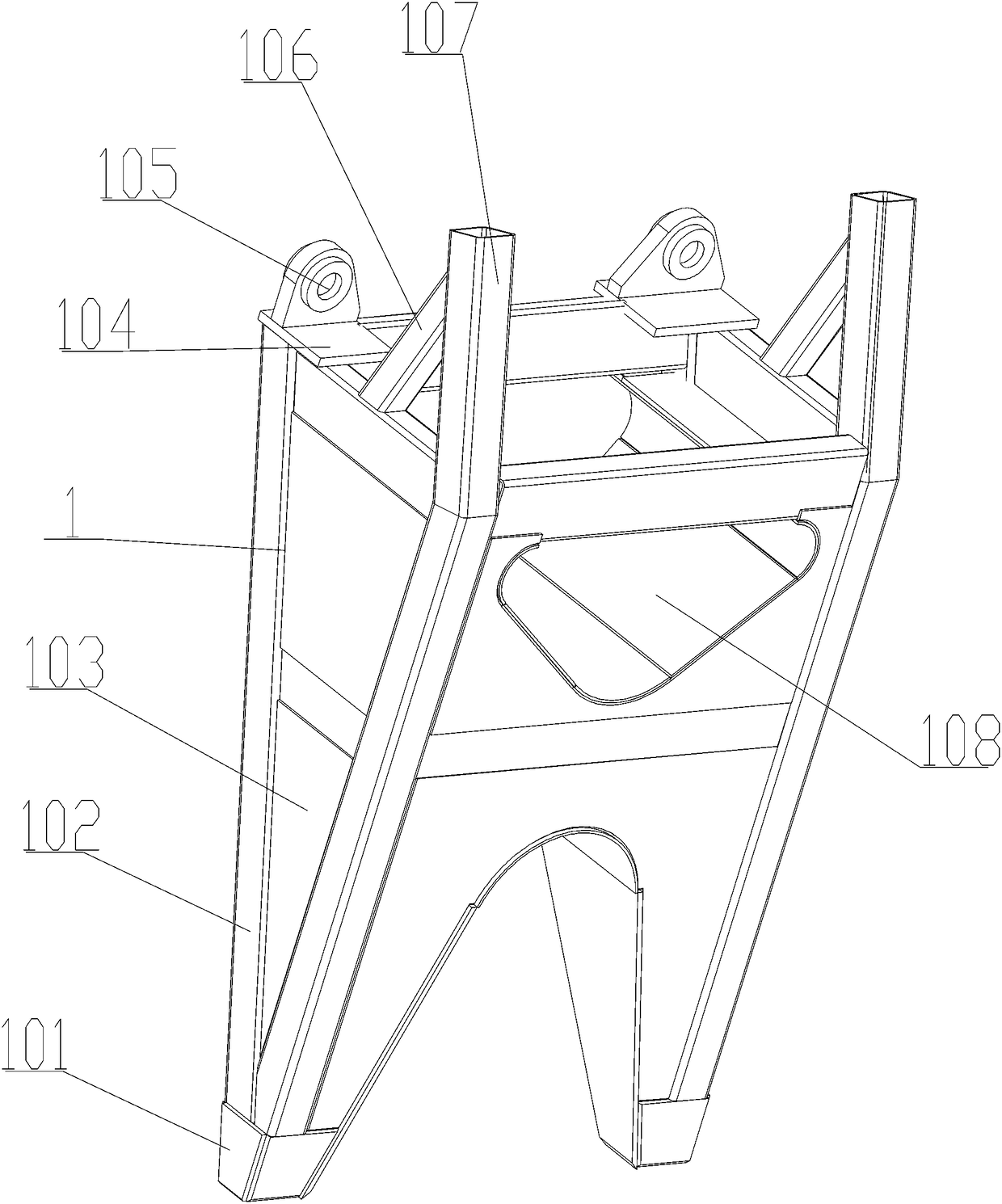

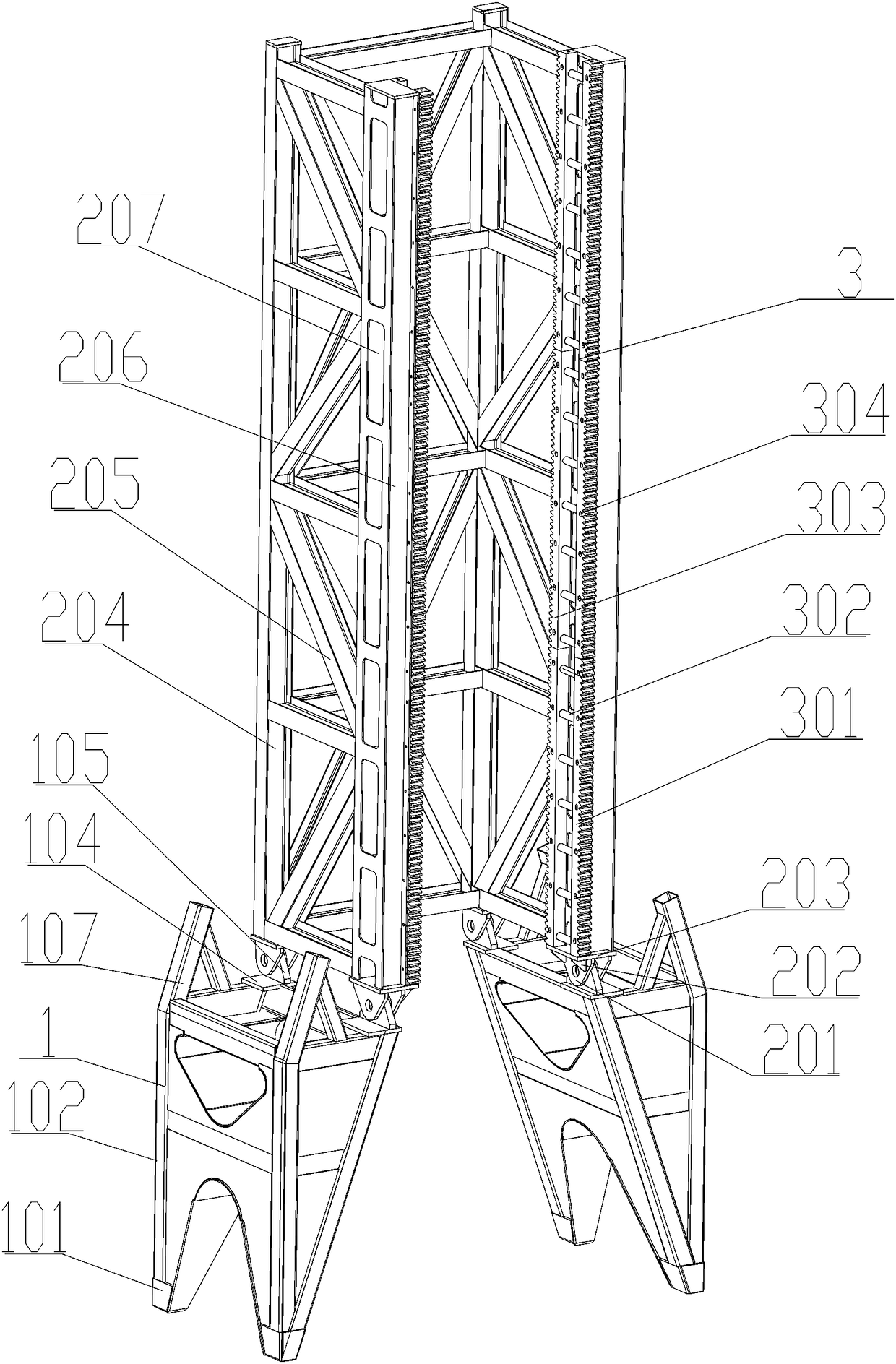

[0035] see Figure 1-5 , a rack and pinion drilling rig derrick structure, which includes a bottom support frame 1 connected to the foundation support at the bottom of the vertical shaft, the bottom support frame 1 is symmetrically arranged, and a bottom section derrick 2 is installed on the top of the two bottom support frames 1. The top of the bottom section derrick 2 is supported by a multi-section intermediate section derrick 5, and the top section derrick 7 is fixedly installed on the top of the top middle section derrick 5; the bottom section rack assembly is fixedly installed on the inner wall of the bottom section derrick 2 3. The middle section rack assembly 4 is fixedly installed on the inner wall of the middle section mast 5 , and the top section rack assembly 6 is fixedly installed on the inner wall of the top section mast 7 . The derrick structure with the above structure can be used for the support and installation of the rack and pinion drilling rig, and the rac...

Embodiment 2

[0042] The installation method of any one of the rack and pinion drilling rig derrick structure, it comprises the following steps:

[0043] Step1: Fix the two symmetrically arranged bottom support frames 1 to the installation foundation at the bottom of the well;

[0044] Step2: Fix the bottom section derrick 2 on the top of the bottom support frame 1;

[0045] Step3: According to the depth of the well, select an appropriate number of middle section derricks 5, and install them on the top of the bottom section derrick 2;

[0046] Step4: Fix the top section derrick 7 on the top of the middle section derrick 5;

[0047] Step5: Fix the bottom section rack assembly 3 , the middle section rack assembly 4 and the top section rack assembly 6 on the inner side walls of the corresponding bottom section derrick 2 , middle section derrick 5 and top section derrick 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com