Automatic taking device for ampoule paper boxes

An automatic reclaiming and carton technology, applied in the field of automatic packaging of ampoules, can solve the problems of low work efficiency and high labor intensity, and achieve the effects of improving production efficiency, reducing production costs, and preventing suction failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

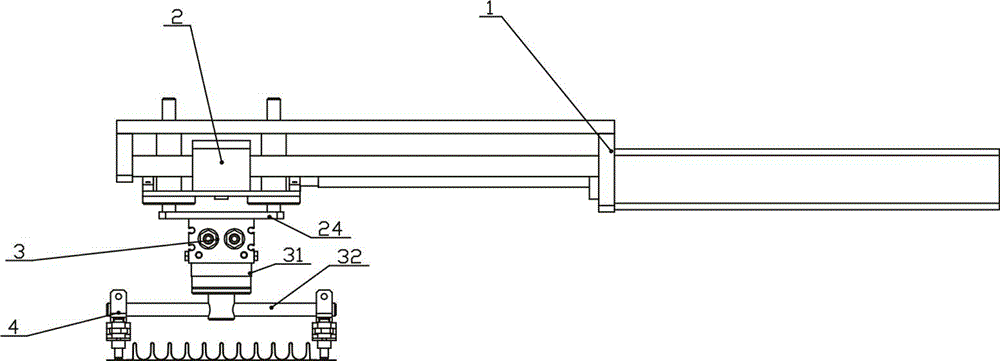

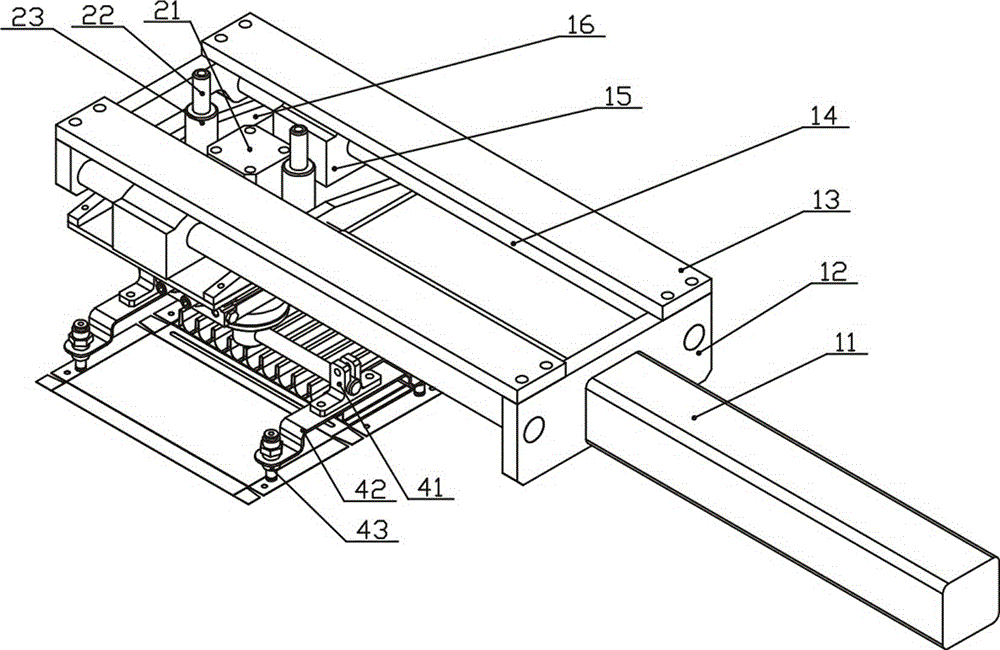

[0014] Such as figure 1 , figure 2 As shown, an automatic feeding device for ampoule cartons is composed of a translation mechanism 1 , a lifting mechanism 2 , a rotation mechanism 3 , and a suction mechanism 4 .

[0015] The translation mechanism 1 is mainly used to realize rapid horizontal movement of paper materials. The translation mechanism 1 is composed of a translation cylinder 11 , a support plate 12 , a fixed plate 13 , a first linear optical axis 14 , a first linear bearing 15 , and a sliding support 16 . The translation cylinder 11 is connected with two supporting plates 12 and two fixing plates 13 . The piston rod of translation cylinder 11 is connected together by bolt group and sliding support 16 right ends. Two first linear optical axes 14 are installed between the two support plates 12 , and two first linear bearings 15 are installed on the two first linear optical axes 14 . The two first linear bearings 15 are connected together with the sliding support 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com