Frost suppression type powder freezing dryer

A cold dryer and powder technology, which is applied in refrigerators, drying, refrigeration components, etc., can solve the problems of poor post environment, fluctuating air temperature, and high energy consumption of cooling units, and achieve reasonable structure, extended service life, and energy saving The effect of system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

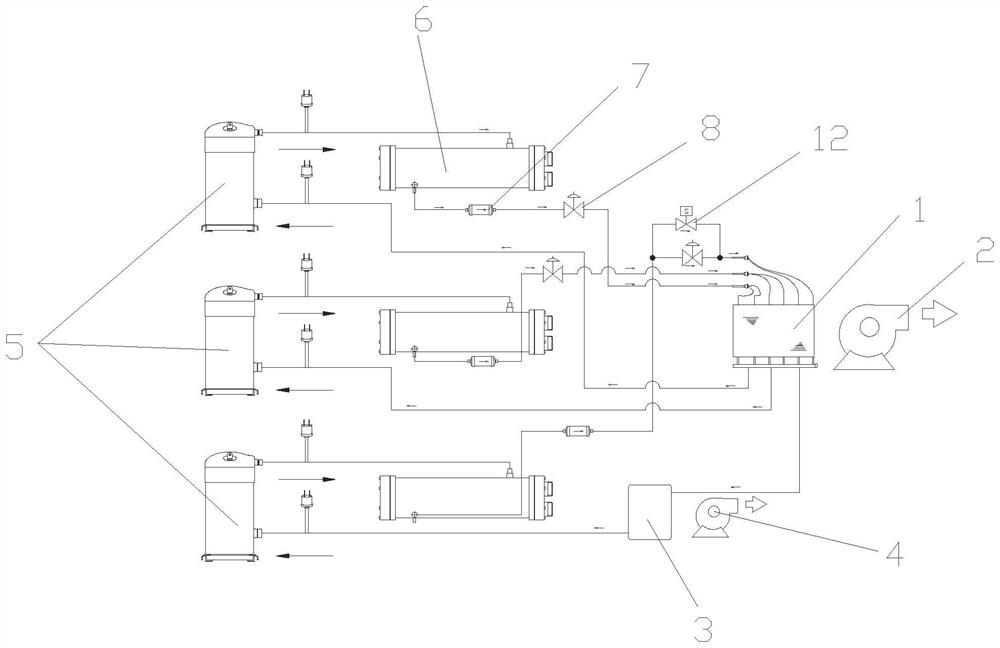

[0016] The present invention will be further described below in conjunction with the accompanying drawings:

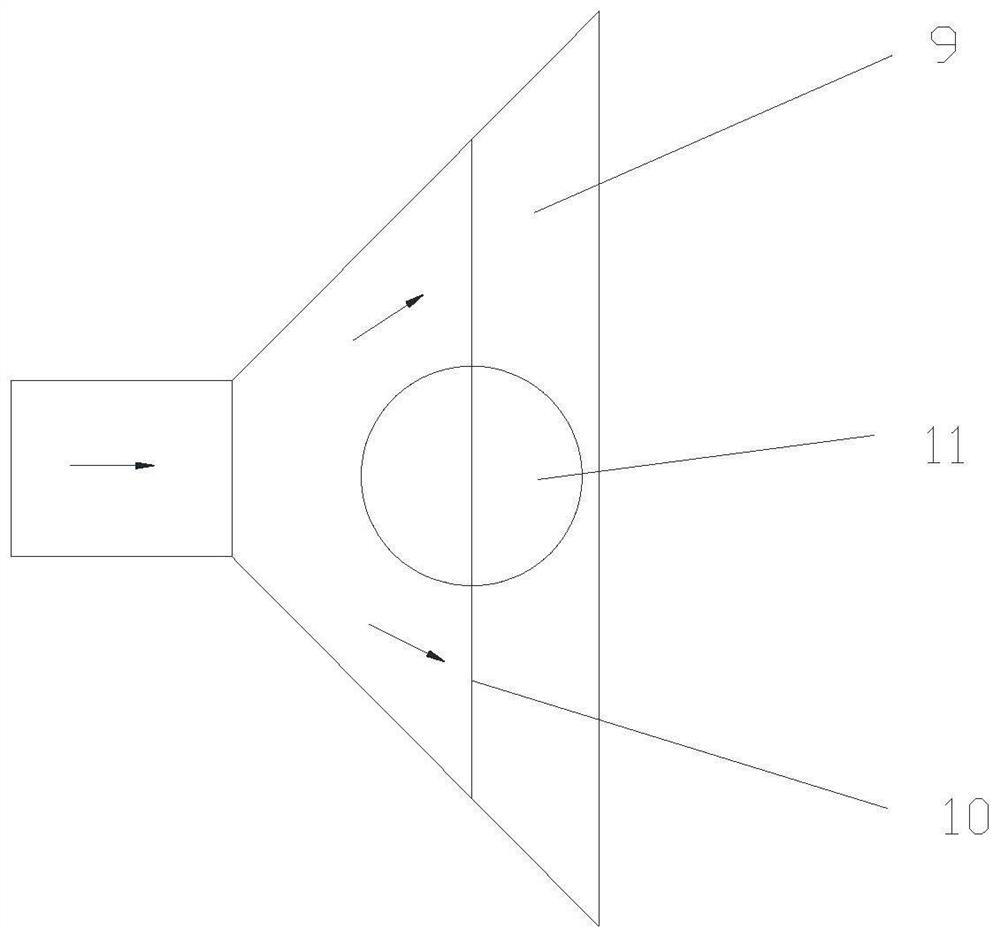

[0017] Referring to the attached drawings: the frost-suppressed powder refrigerating and drying machine in this embodiment includes a frame, and a plurality of parallel multi-stage cooling circuits are arranged in the frame, and the cooling circuits at all levels are connected to the same heat exchanger 1 , one side of the heat exchanger 1 is provided with a first induced draft fan 2 that uses the heat exchanger 1 to supply air for grinding, and a second heat exchanger 3 is connected in series at the outlet end of the heat exchanger 1 in the last stage of the cooling circuit. One side of the second heat exchanger 3 is provided with a post air conditioner blower 4, and the second heat exchanger 3 cooperates with the post air conditioner blower 4 to form a post air conditioner component that creates a cooling and dust-less operation post space for the staff.

[0018] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com