Rotary shaft with a vent groove

A technology of ventilation slots and rotating shafts, which is applied in the direction of shafts, shafts and bearings, mechanical equipment, etc., and can solve problems such as the inability to ensure the effect of airflow delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above-described features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale and components with similar related characteristics or features may have the same or similar reference numbers.

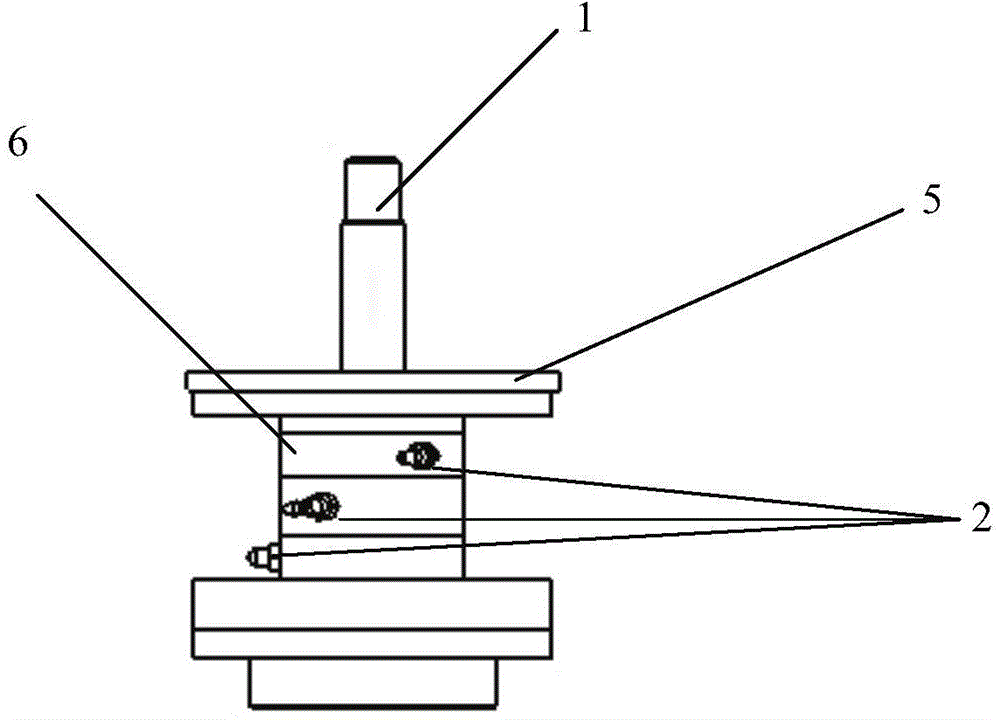

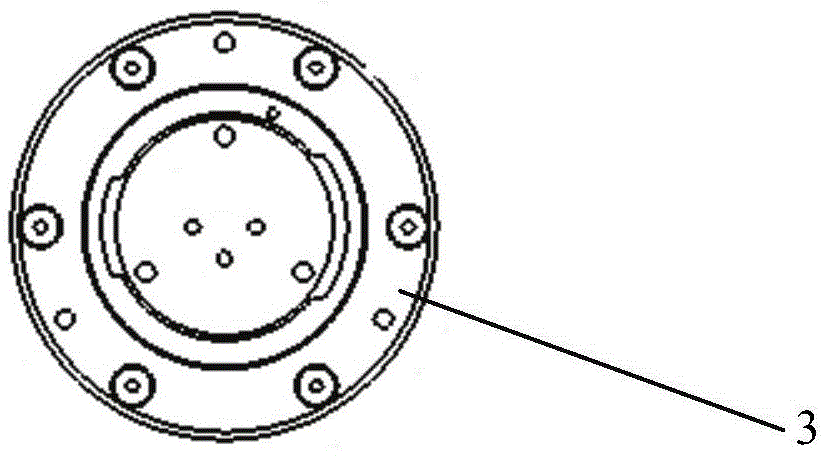

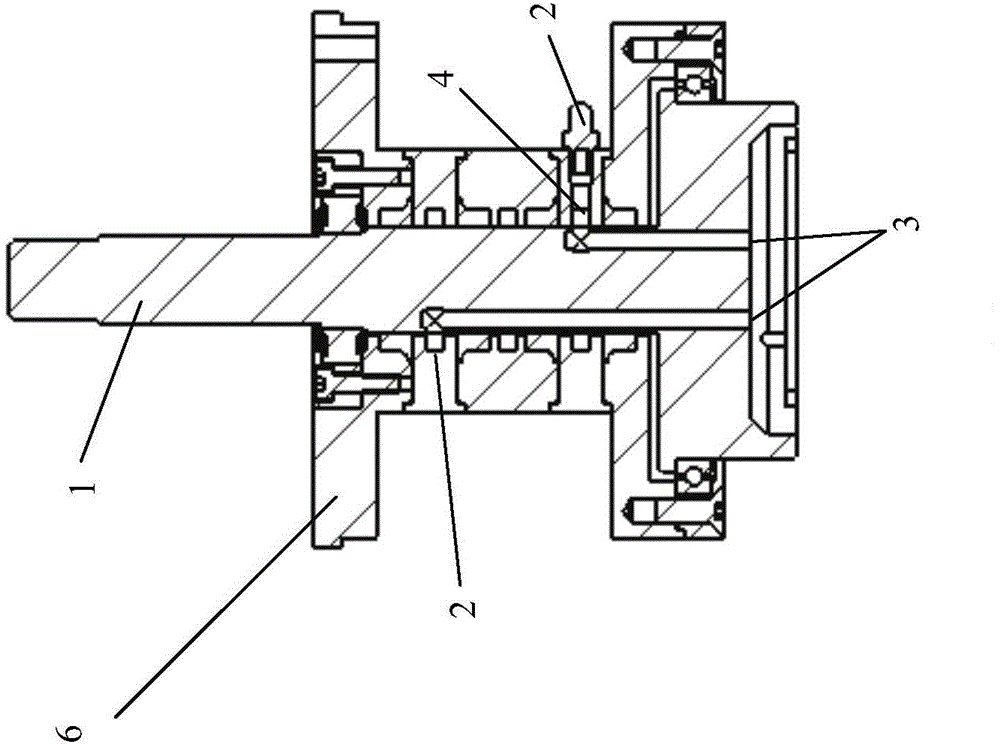

[0023] figure 1 The outline of the preferred embodiment of the rotating shaft with ventilation grooves of the present invention is shown, Figure 2A and 2B The cross-sectional structure of such a rotating shaft with ventilation grooves is shown separately. see also figure 1 , Figure 2A and 2B , the rotating shaft with ventilation groove in this embodiment includes a rotatable shaft body 1 with a ventilation groove inside, a shaft sleeve 6 with a fixed position, a multi-way air inlet 2 on the shaft sleeve, and an air guide ring in the shaft sleeve. Space 4, and multiple ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com