A Prediction Method of Visual Feature of Breakout Based on Improved Neural Network

A neural network and BP neural network technology, applied in the field of iron and steel metallurgical continuous casting detection, can solve problems such as false alarms, achieve the effects of reducing the number of false alarms, improving the accuracy of forecasting, improving the accuracy of forecasting and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings.

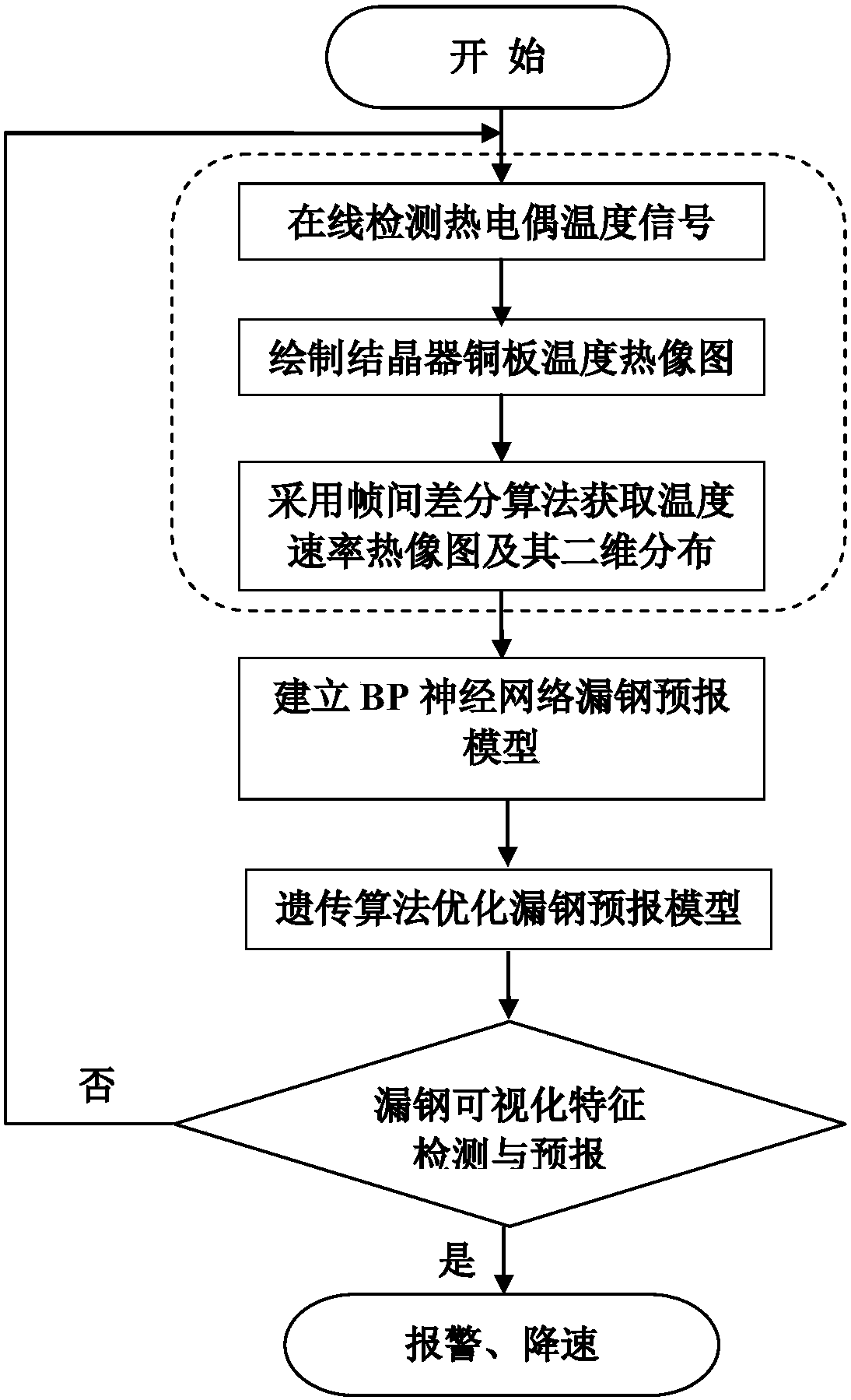

[0058] figure 1 It is based on the improved BP neural network breakout visualized feature prediction block diagram. Depend on figure 1 It can be seen that a method based on the improved BP neural network breakout visual feature prediction method includes: extracting the visual features of the temperature anomaly area of the breakout; establishing a three-layer BP artificial neural network breakout prediction model; Optimize; use the model to detect and predict the visual features of steel breakout online, and the detection steps are as follows:

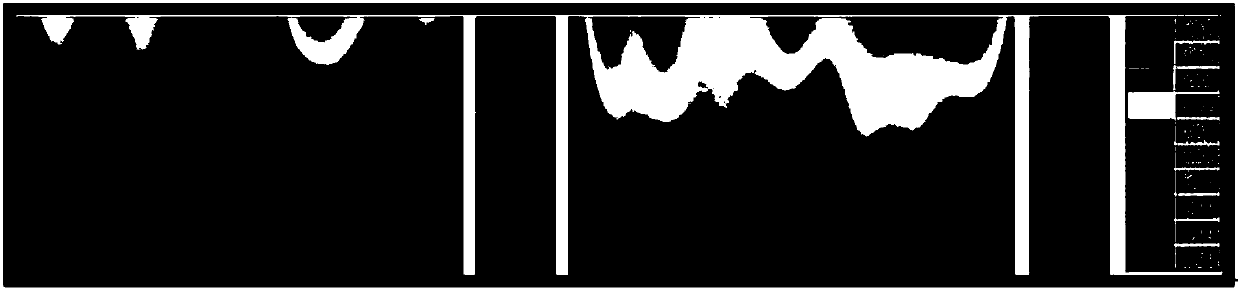

[0059] 1) Crystallizer temperature rate thermal imaging and visualization feature extraction

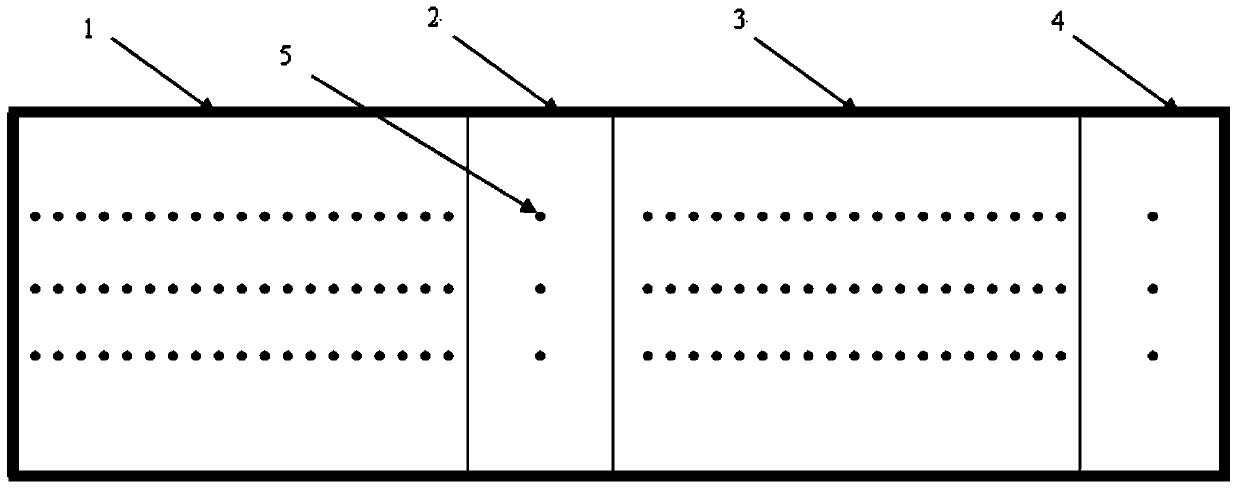

[0060] figure 2 It is a schematic diagram of four crystallizer copper plates unfolded and thermocouples arranged. The length of the slab continuous casting mold is 900mm, and it is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com