Crystallizer bleed-out visual forecasting method based on machine vision

A technology of machine vision and crystallizer, which is applied in the field of iron and steel metallurgical continuous casting detection, can solve the problems of restricting the promotion of methods, application effects, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

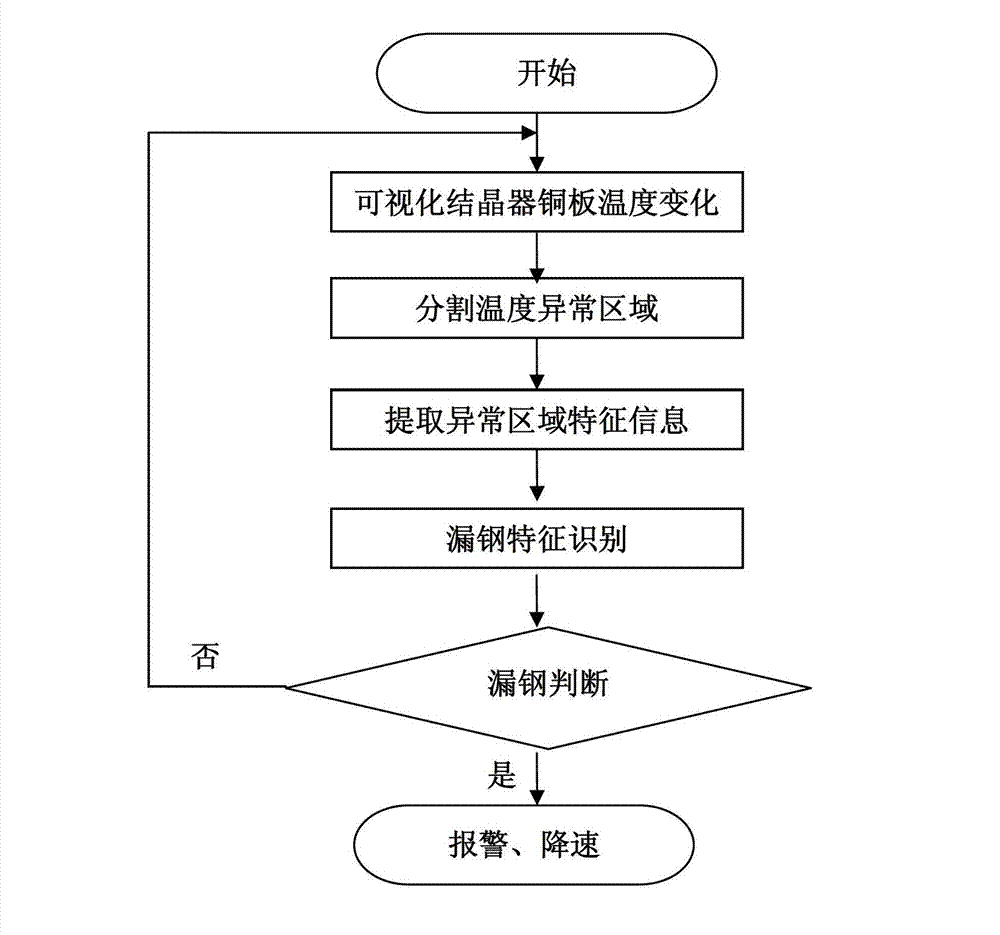

[0061] figure 1 It is a machine vision visual breakout prediction block diagram. Depend on figure 1 It can be seen that the visual prediction method of continuous casting mold breakout based on machine vision is divided into the following four parts: visualizing mold copper plate temperature change, segmenting abnormal temperature areas, extracting feature information of abnormal areas, and identifying and judging breakout features.

[0062] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings.

[0063] The first step, visualization of mold copper plate temperature and its change rate

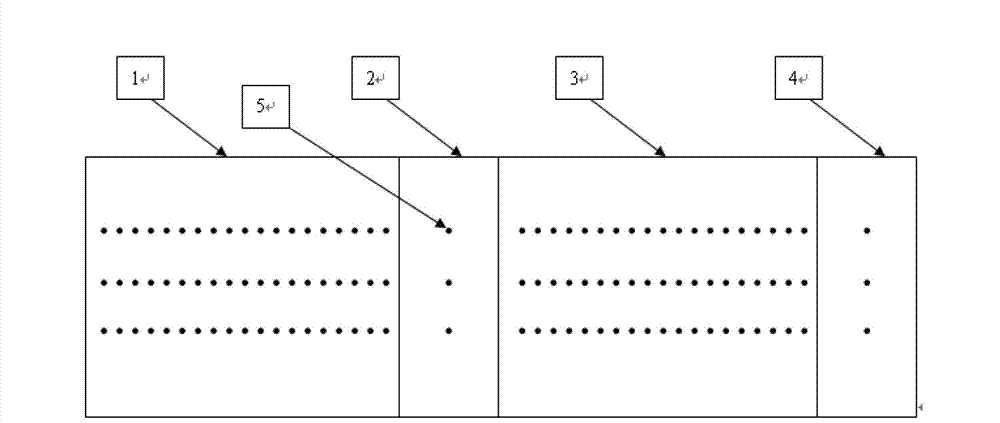

[0064] figure 2 It is a schematic diagram of four crystallizer copper plates unfolded and thermocouples arranged. The length of the slab continuous casting mold is 900mm, and it is composed of four copper plates, including a pair of wide-faced copper plates and a pair of narrow-faced copper plates. 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com