Conductor temperature measurement type T-shaped cable joint device

A technology of cable joints and receiving devices, which is applied in the direction of measuring devices, electrical devices, and parts of connecting devices. It can solve problems such as very high requirements for stability and maintenance-free, signal penetration, and difficulties, so as to improve monitoring The effect of reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

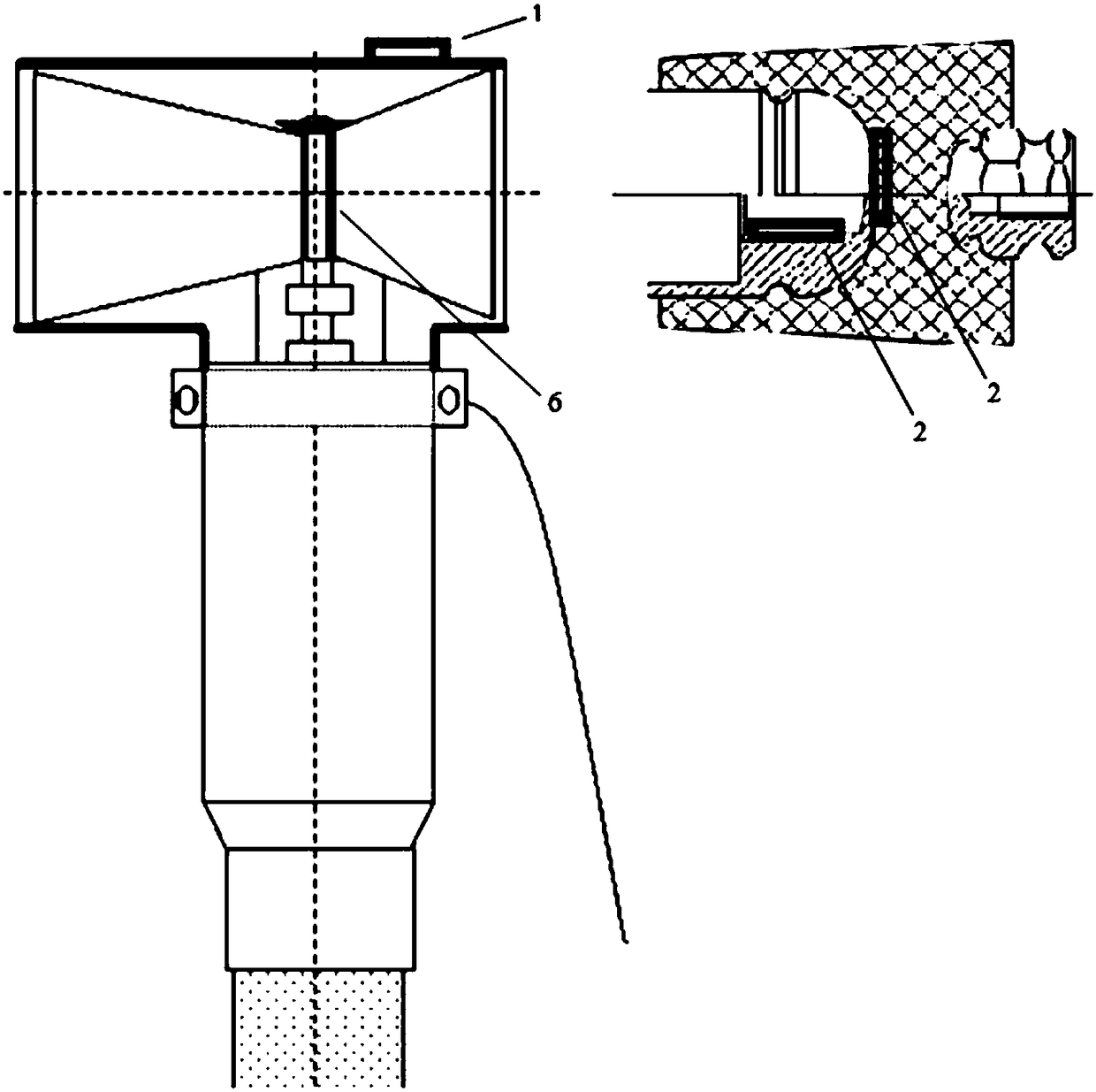

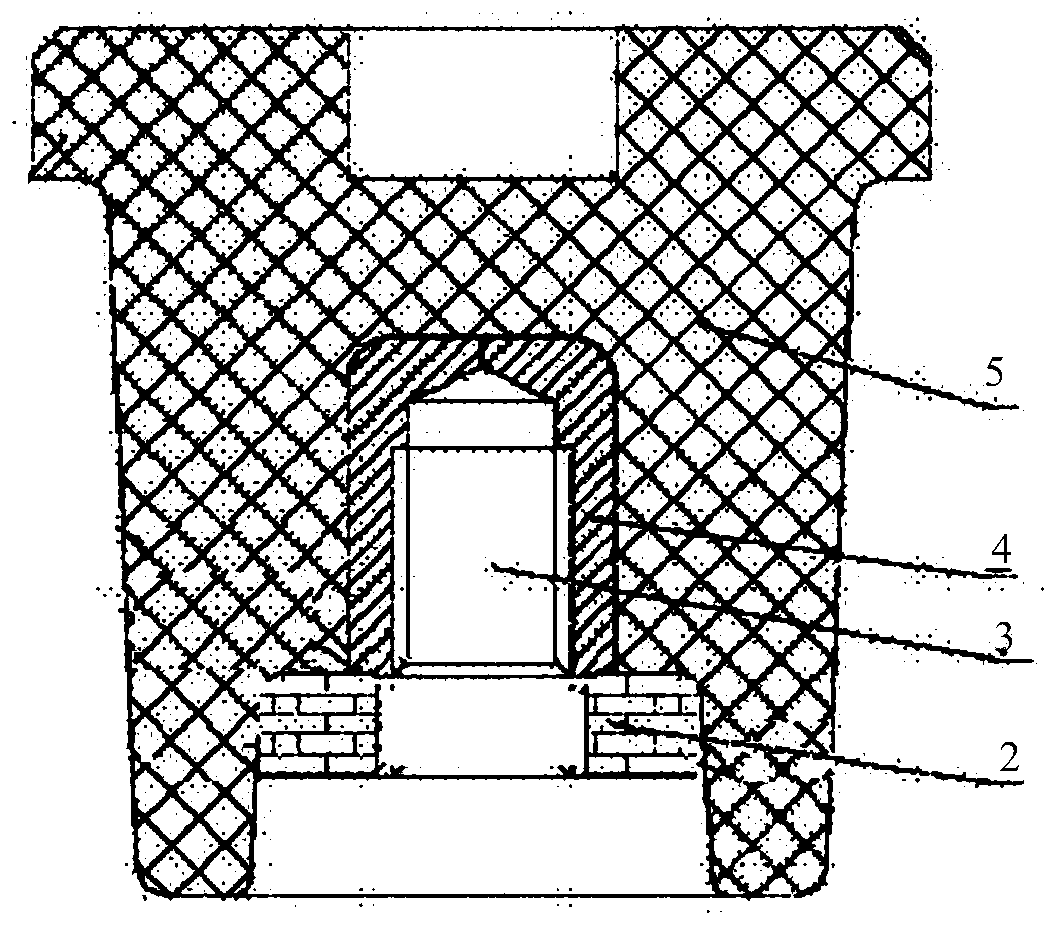

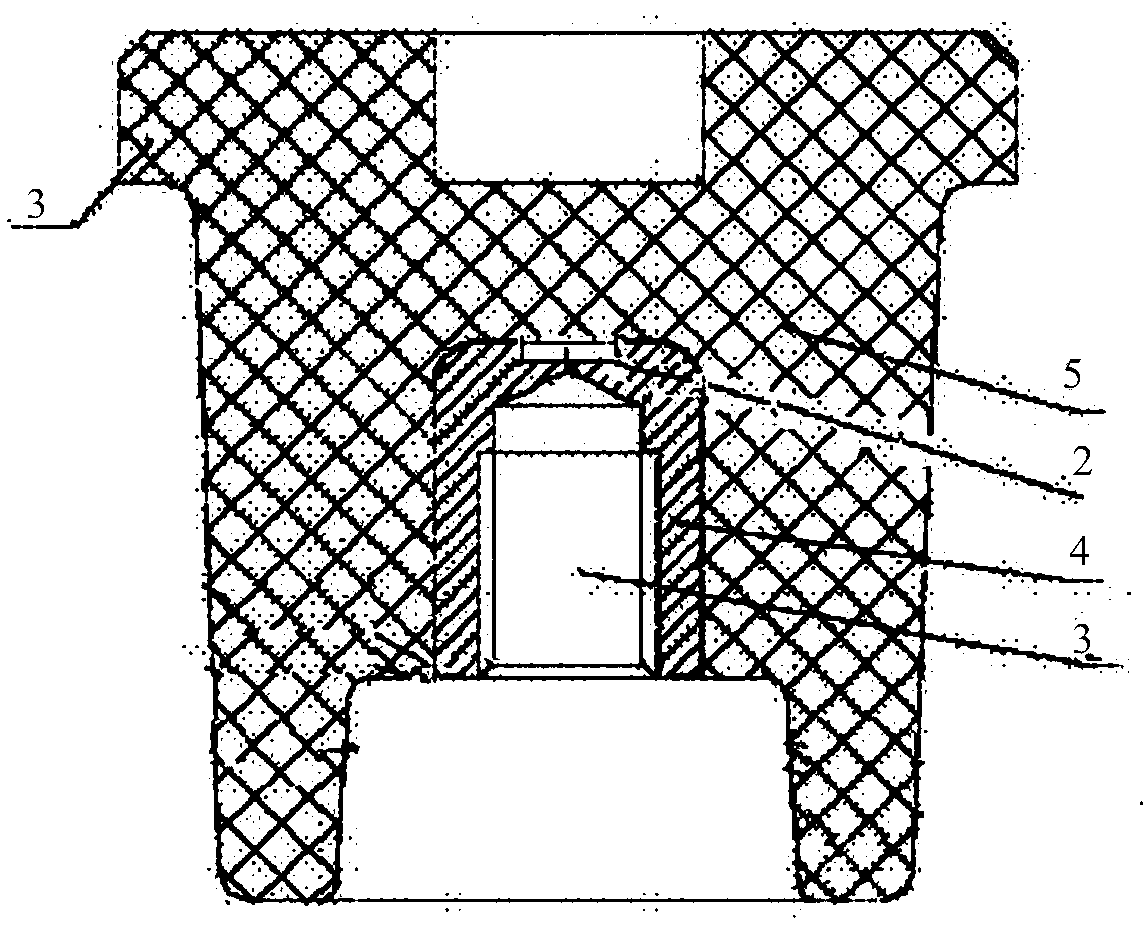

[0017] figure 1 It is the position diagram of temperature measuring type T-joint sensor and receiving device. The external receiving device 1 is placed outside the body of the T-shaped joint, and placed in a concentric circle with the built-in sensor 2 . The placement position of the built-in sensor 2 is related to the internal design of the T-joint. When there is a gap in the cavity surrounded by the conductor terminal 6 and the metal insert 4, the built-in sensor 2 can be placed on the inner wall of the metal insert 4. For the placement method, see figure 2 mentioned. When there is no gap in the cavity surrounded by the conductor terminal 6 and the metal insert 4, it can only be placed at the tail 5 of the metal insert 4. For the placement method, see image 3 .

[0018] figure 2 The built-in sensor 2 is placed on the inner wall of the metal insert 4. After the product is installed, the conductor terminal 6 will be closely combined with the metal insert 4. Only when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com