Press bearing time tester for asphalt mixture and test method thereof

An asphalt mixture and testing device technology, applied in the direction of material thermal development, etc., to achieve the effects of convenient use and maintenance, accurate data collection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

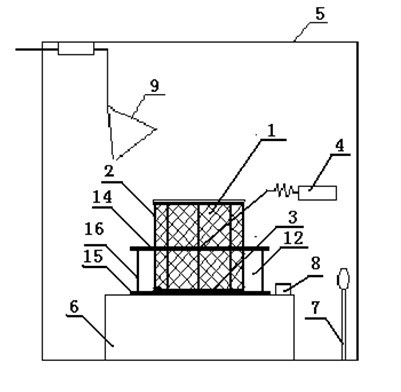

[0049] Such as Figure 1 to Figure 3 As shown, the test device for the rolling time of the asphalt mixture of the present invention includes a storage tank 1, an insertion and tamping device, a temperature sensor, a data acquisition system 4 and an environmental chamber 5;

[0050] The storage tank 1 is a cylinder frame, which is composed of 8 vertical bars 2 and a bottom plate 3. The inner wall of the storage tank 1 is equipped with a grid; the grid plays a centralized role in fixing the asphalt mixture without affecting The asphalt mixture is in full contact with the simulated environment of the environmental chamber 5 during the experiment;

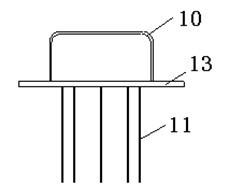

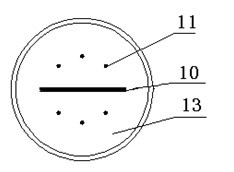

[0051] The inserting and tamping device comprises a circular pressing plate 13, one side of the pressing plate 13 has a handrail 10, and the other side of the pressing plate 13 has 9 evenly distributed tamping rods 11; compacted;

[0052] There is a stage 6 and a fan 7 at the bottom of the environmental box 5, and a fixed mount 12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com