Positioning jig for in-mold injection-molded steel sheets

A positioning fixture and in-mold injection molding technology, applied in the direction of coating, etc., can solve the problems of steel sheet deviation and movement, the manipulator is not in the correct position, and the degree of freedom of the manipulator cannot be limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

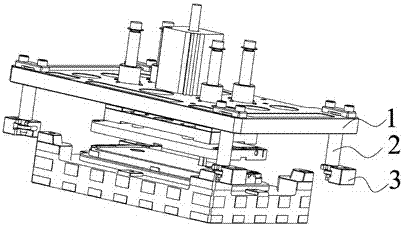

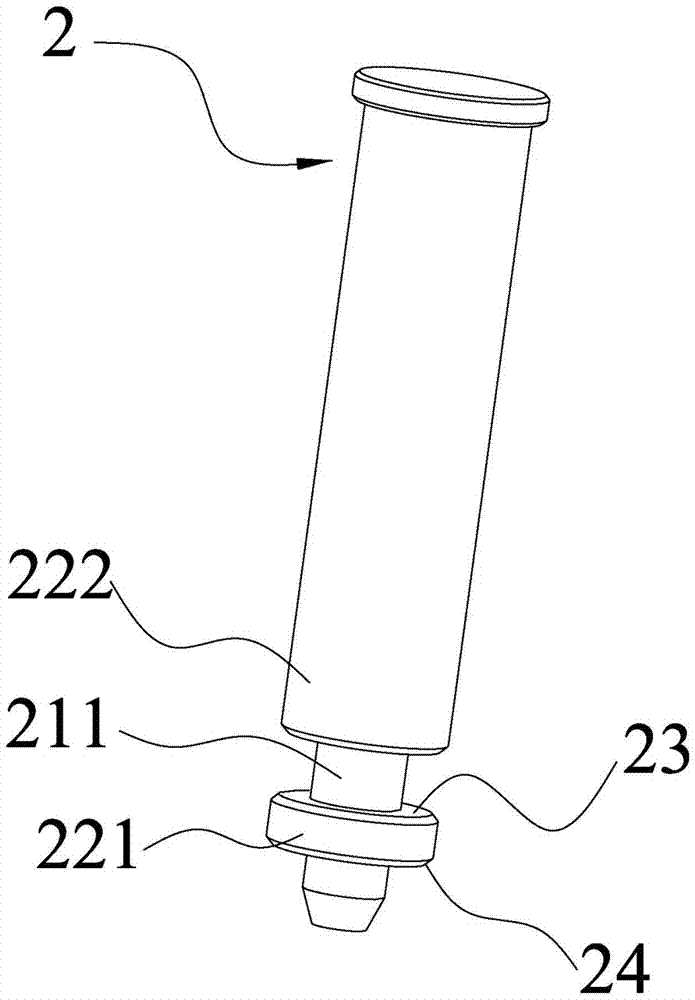

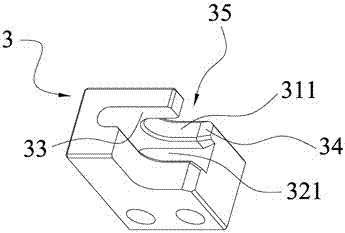

[0037] The positioning fixture of the inner injection molded steel sheet of the present invention, such as figure 1 As shown, it includes a base plate 1 and a positioning column 2, one end of the positioning column 2 is fixed to the base plate 1 by a screw, and the other end of the positioning column 2 is facing the injection mold 4 for the required positioning (see Figure 5 As shown) one end is provided with a stepped shaft. Such as figure 2 As shown, the machining of the stepped shaft is simple, just cut off a part of the commonly used positioning column and form the journal. Such as Figure 5 As shown, the positioning jig also includes a positioning insert 3...

Embodiment 2

[0041] Embodiment 2 of the positioning fixture for injection molding steel sheets in the present invention, the main technical scheme of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment adopt the explanation in Embodiment 1, here No further details will be given. The difference between this embodiment and embodiment 1 is that, as Figure 7 As shown, the stepped shaft includes a first journal 211, a second journal 212 and three shaft bodies respectively located on the sides of the two journals, and the three shaft bodies are respectively the first shaft body 221 and the second shaft body 222 And the third shaft body 223, the two shaft bodies near the end of the stepped shaft are the first shaft body 221 and the second shaft body 222; as Figure 8 As shown, the stepped groove includes two journal grooves and two axle body grooves, which are respectively a first journal groove 311 , a second journal groove 312 , a first axle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com