Reversing valve and sliding block thereof

A technology for reversing valves and sliders, which is applied to valve devices, multi-way valves, sliding valves, etc., and can solve problems such as jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

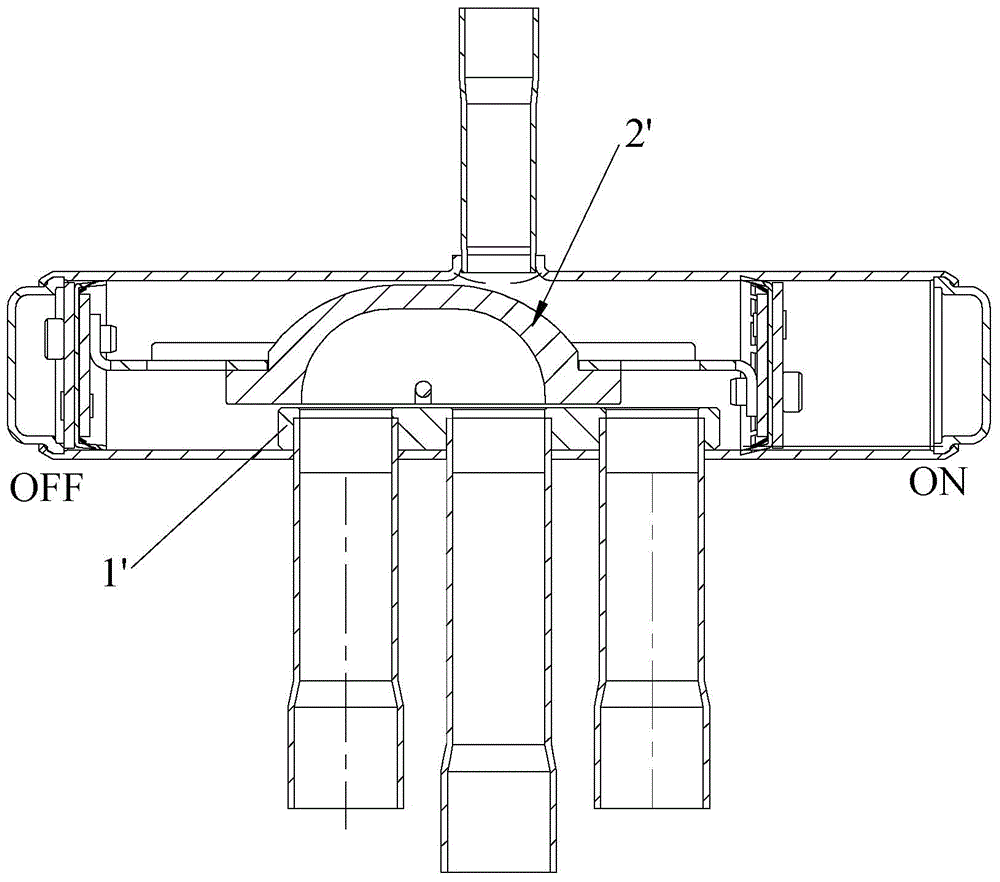

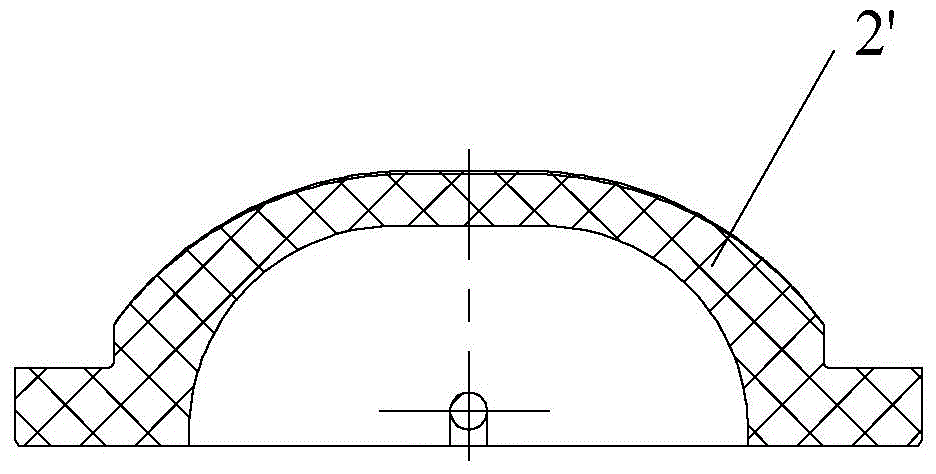

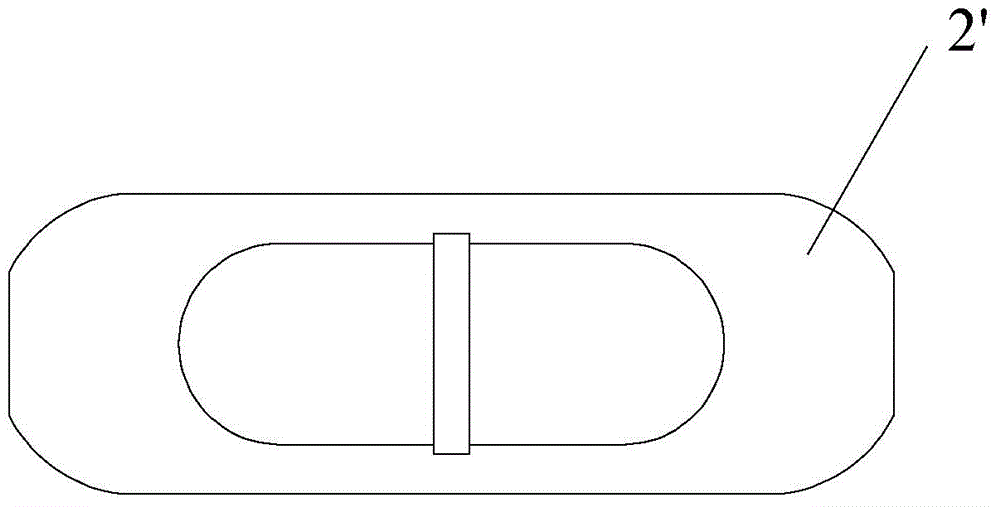

[0035] After a series of experimental verifications, the inventor found that when the four-way valve of the prior art is in use, during the reversing process from the OFF side to the ON side, the force state of the slider 2' is as follows: Figure 4 shown. The slider 2' receives the driving force F1 provided by the connecting rod, and its stress point is located at the horizontal position where the connecting rod contacts the slider 2'. In addition, the slider 2' is also subjected to the friction force f of the contact surface between the slider and the valve seat during the reversing process. 'The thrust of the slider 2' and the reverse friction f of the valve seat 1' are not on the same lev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap