A dual-mode fine-tuning 3D image shooting bracket

An image shooting and 3D technology, which is applied in the direction of machine/support, supporting machine, optics, etc., can solve the problems of lack of adjustment function of converging surface, expensive 3D shooting equipment, and low adjustment accuracy, so as to improve visual experience and realize fine Adjustment, improve the effect of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

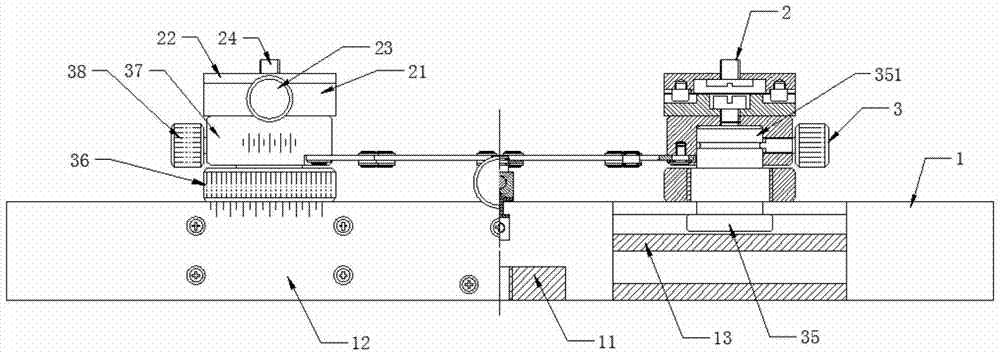

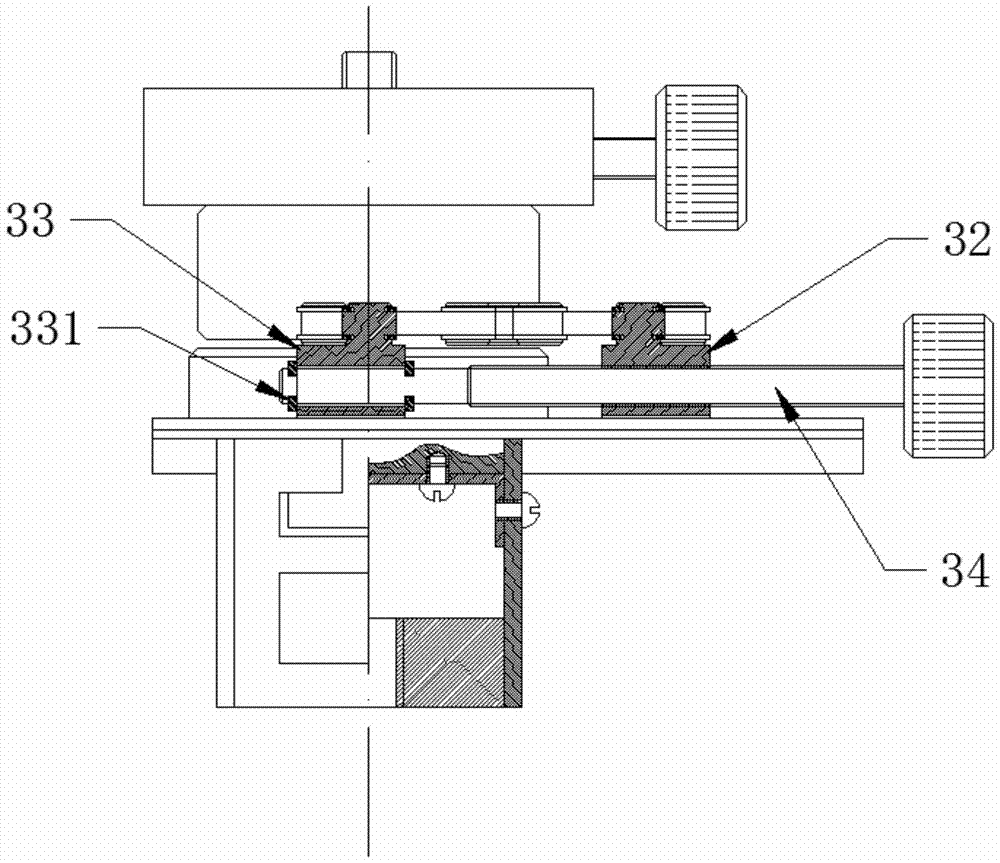

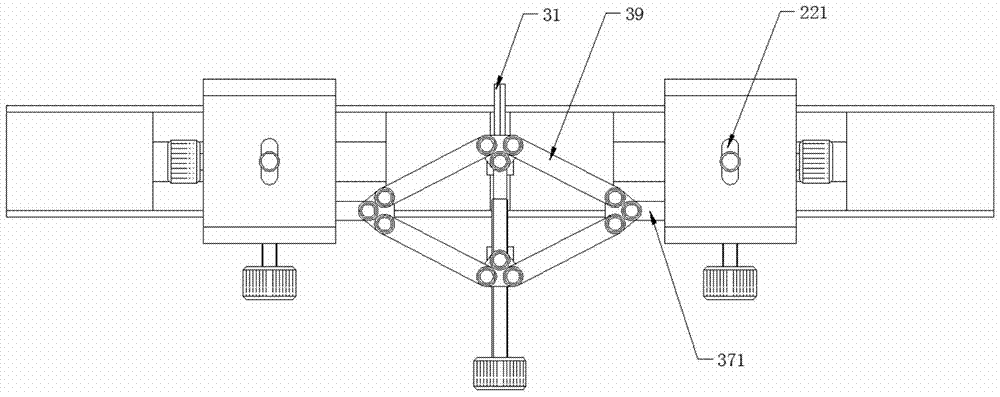

[0023] See Figure 1 to Figure 3 , the dual-mode fine-tuning 3D image shooting bracket of this embodiment includes a bracket body 1 , a camera fixing component 2 and a dual-mode precise adjustment mechanism 3 for the interpupillary distance and the converging surface.

[0024] The interpupillary distance and converging surface dual-mode precise adjustment mechanism 3 includes a longitudinal guide rail 31, an active longitudinal slider 32, a driven longitudinal slider 33, an operating rod 34, a horizontal slider 35, a pupil distance fixing ring 36, a converging surface adjustment ring 37, Convergence surface fixing button 38 and adjustment link 39. The longitudinal guide rail 31 is arranged in the middle part of the support body 1 . Both the active longitudinal slider 32 and the driven longitudinal slider 33 are longitudinally slidably connected to the longitudinal guide rail 31 . The operating rod 34 is threadedly connected with the active longitudinal slider 32 . The drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com