Performance evaluating method suitable for PID control loop in tobacco processing process

A control loop and process technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of unable to obtain the optimal solution, the objective function does not consider the cost effect, the calculation speed is slow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

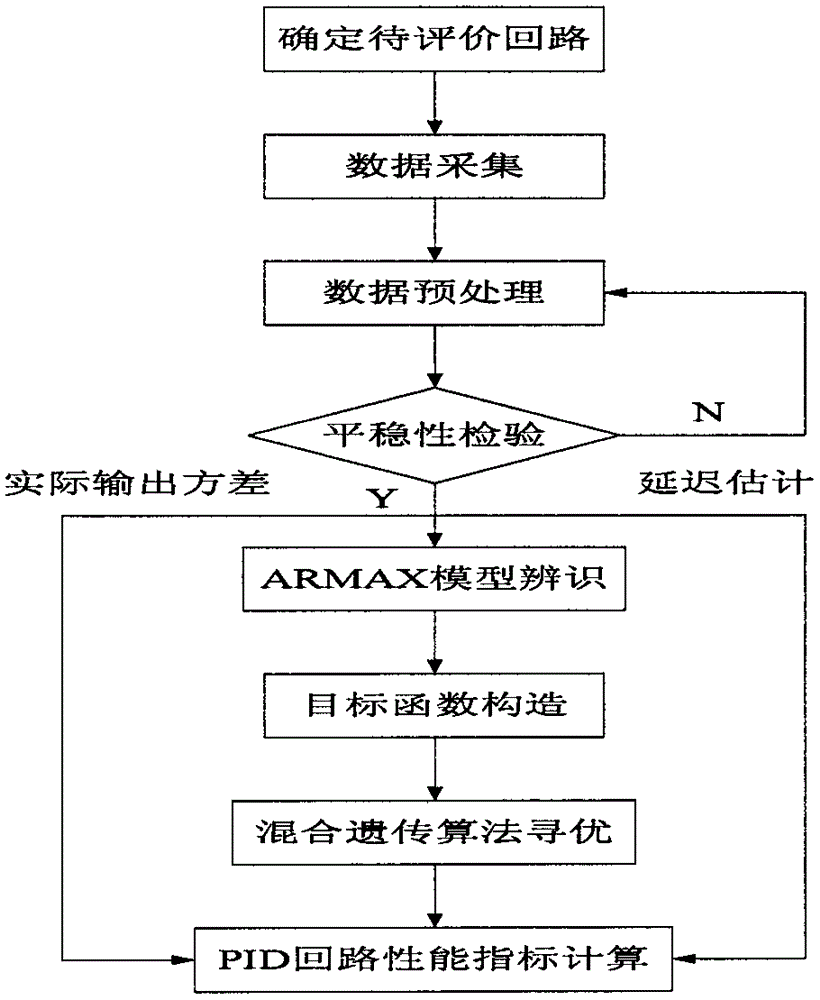

[0044] Taking the outlet moisture control circuit of SH625 shred drying machine (scale flow rate before drying 5400kg / h) in a cigarette factory as the evaluation object, the specific steps for performance evaluation of the outlet moisture PID control loop within a batch are as follows ( image 3 ):

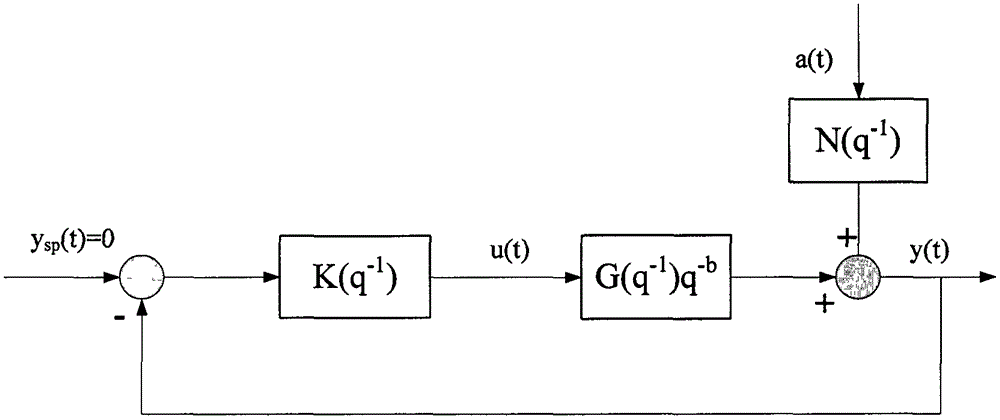

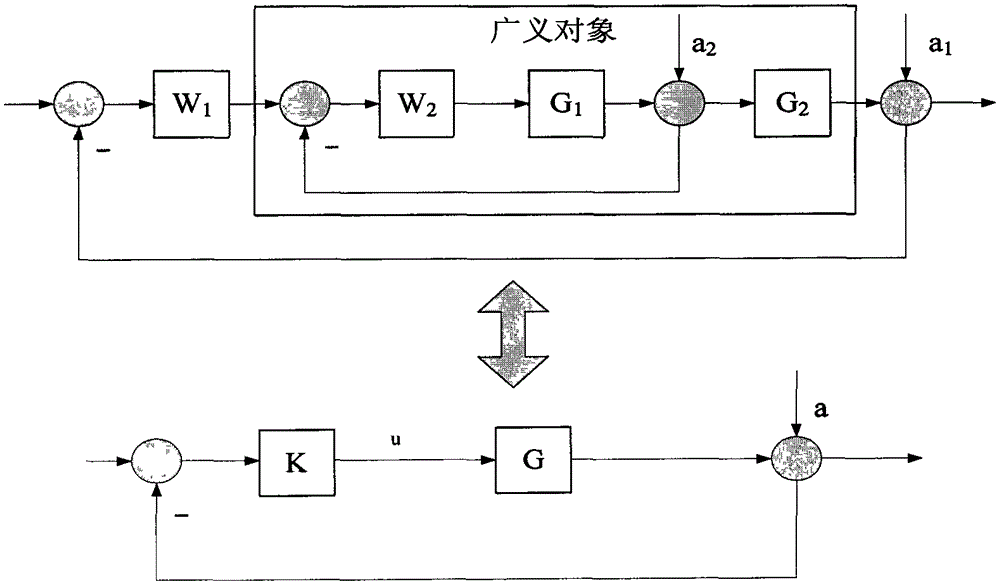

[0045] (1) Select the moisture control loop at the outlet of the silk drying process as the evaluation object, and conduct an equivalent single-loop PID loop analysis on the moisture cascaded PID loop ( figure 2 shown), determine the operating data as the controlled variable outlet moisture and the controlled variable steam pressure;

[0046] (2) When a batch of shredded tobacco has completely entered the drying machine (that is, the normal production stage), set the rotating speed of the drying drum to 28r / min; keep the opening of the damp damper at 69.50%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com