Cassette positioning device and semiconductor processing equipment

A technology for positioning devices and cassettes, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as reduced transmission and process efficiency, wafer 6 offset, and manipulators cannot normally pick up wafers, etc., to avoid wafer position Offset or drop, ensure normal film pickup, improve transmission and process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

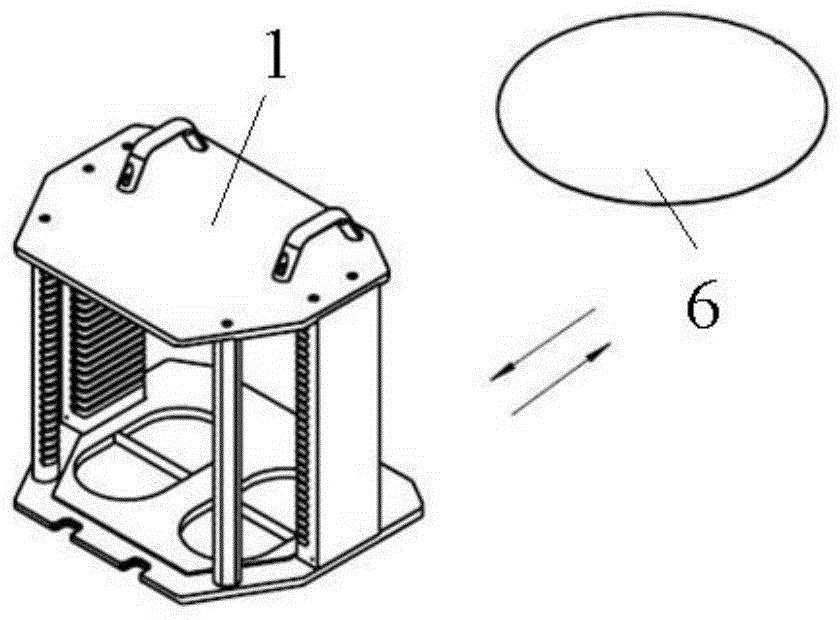

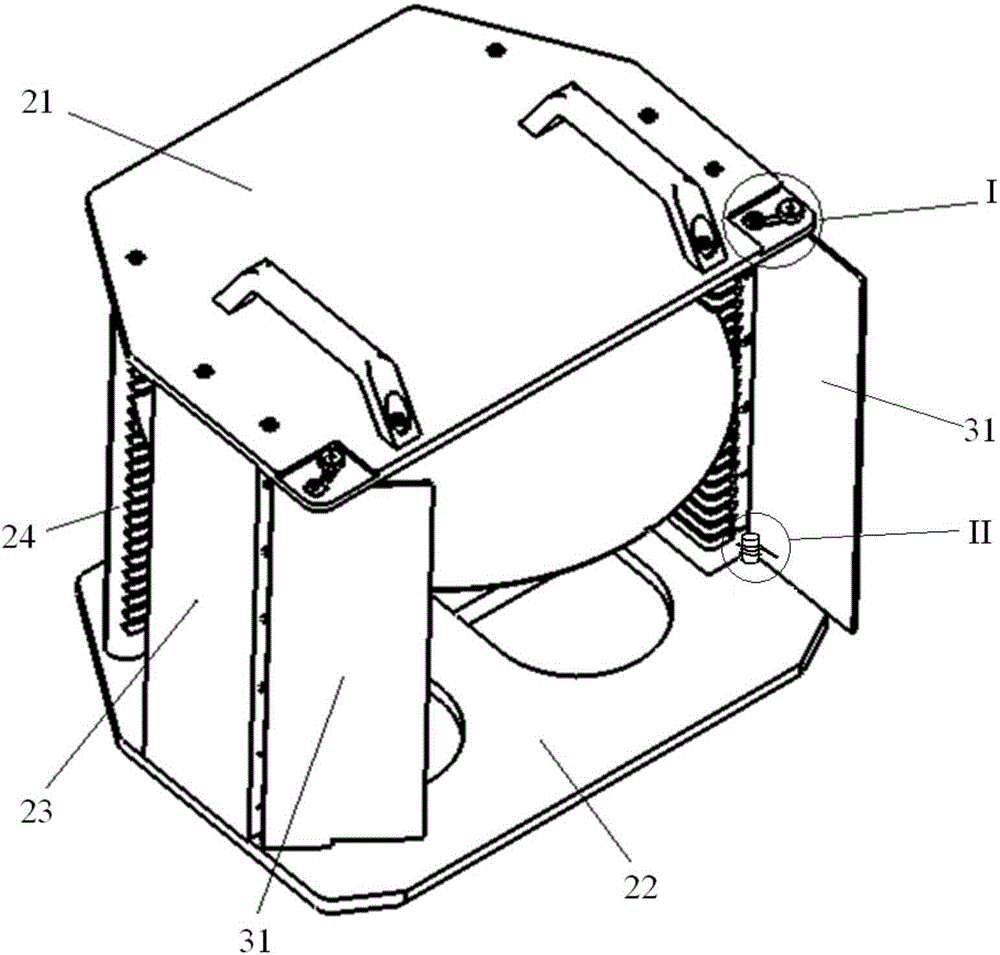

[0035] Please also refer to Figure 3A-Figure 4D , the sheet box is composed of a top plate 21, a bottom plate 22, a side frame 23 and a rear pillar 24. One side has an open frame structure with an opening (located on the side opposite to the rear pillar 24), and the inner surfaces of these parts are correspondingly provided with along the The multi-layer notches arranged at intervals in the vertical direction are used to support the wafer.

[0036] The cassette positioning device includes a limit gate 31 and a positioning mechanism. Wherein, there are two limit doors 31 , which are respectively rotatably connected to the two side frames 23 . By rotating the two limiting doors 31 synchronously, both of them can be located at the first position that blocks the movement of the wafers in the cassette, or at the second position that does not block the movement of the wafers in the cassette. The so-called second position of non-blocking movement of the wafers in the cassette mean...

no. 2 example

[0047] Compared with the above-mentioned first embodiment, the film cassette positioning device provided by the embodiment of the present invention also includes a limit door 31 and a positioning mechanism, and the positioning mechanism also includes an arc guide rail, a sliding piece and a locking piece, wherein the three The function is the same as that of the above-mentioned first embodiment, and the structure of the arc-shaped guide rail is the same as that of the above-mentioned first embodiment, but the structure of the sliding part and the locking part is different from the above-mentioned first embodiment. Only the differences between this embodiment and the above-mentioned first embodiment will be described in detail below.

[0048] Please also refer to Figure 5A-6B , in this embodiment, two first protrusions 214 opposite to each other are provided at the middle positions of the respective hole walls of the first positioning hole 212 and the second positioning hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com