A multi-degree-of-freedom cutting mechanism

A technology of cutting mechanism and degree of freedom, which is applied to harvesters, picking machines, agricultural machinery and tools, etc., can solve the problems of banana cutting stop, labor-intensive, and low cutting efficiency, so as to reduce frictional resistance, ensure independence, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

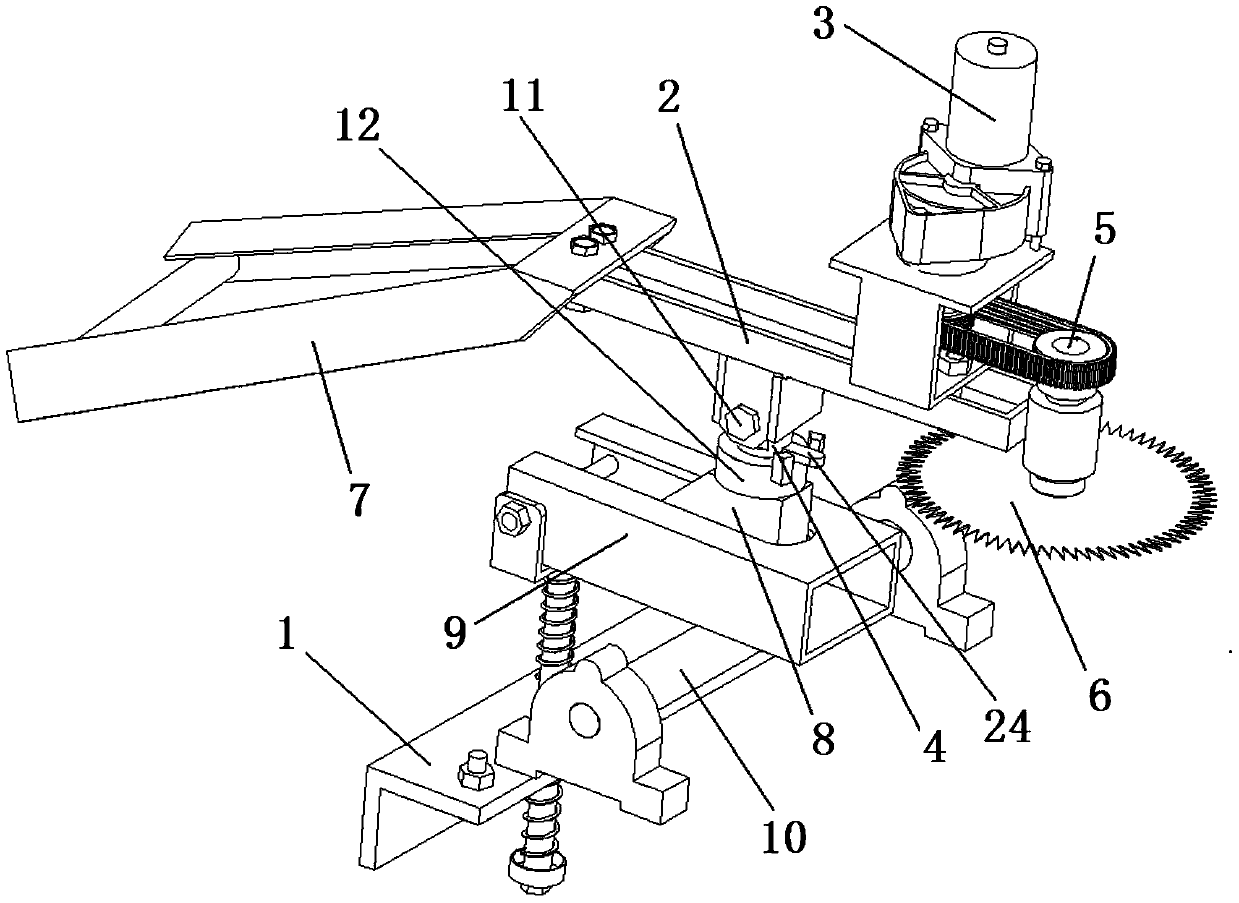

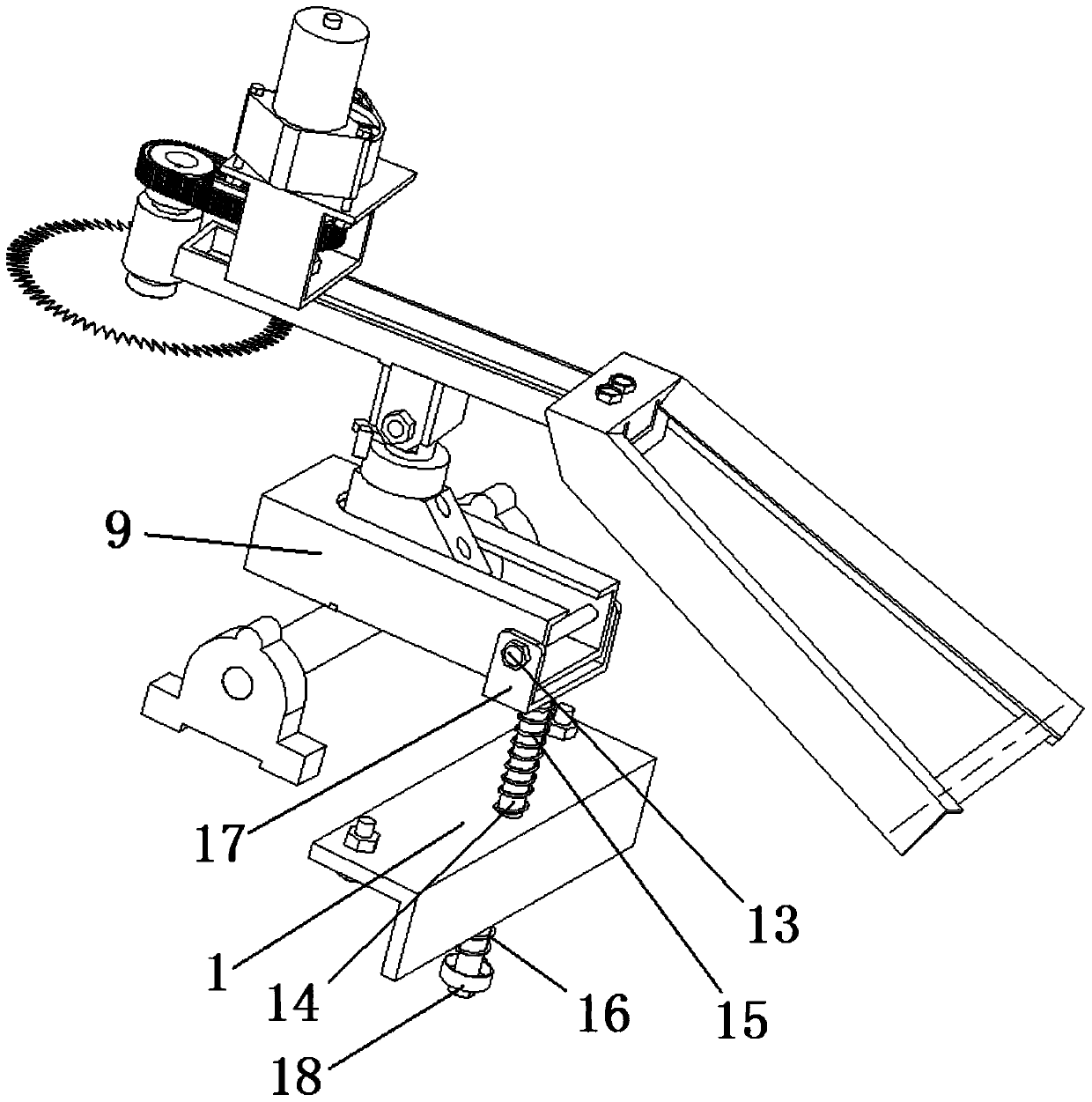

[0026] A multi-degree-of-freedom cutting mechanism, including a frame 1, a tool holder 2, a motor 3, a connecting block 4, a transmission mechanism, a first rotating shaft 5, a cutter head 6, a handle 7, a slider 8, a chute 9 and a second rotating shaft 10,

[0027] The bottom of the tool holder 2 is connected to the connecting block 4 through the fastener 11, the connecting block 4 is connected to the slider 8 through the first rotating pair 12, the slider 5 is installed in the chute 9, and the chute 9 is fixed on the second rotating shaft 10, the two ends of the second rotating shaft 10 are installed on the top of the vehicle frame 1 through bearings and bearing seats;

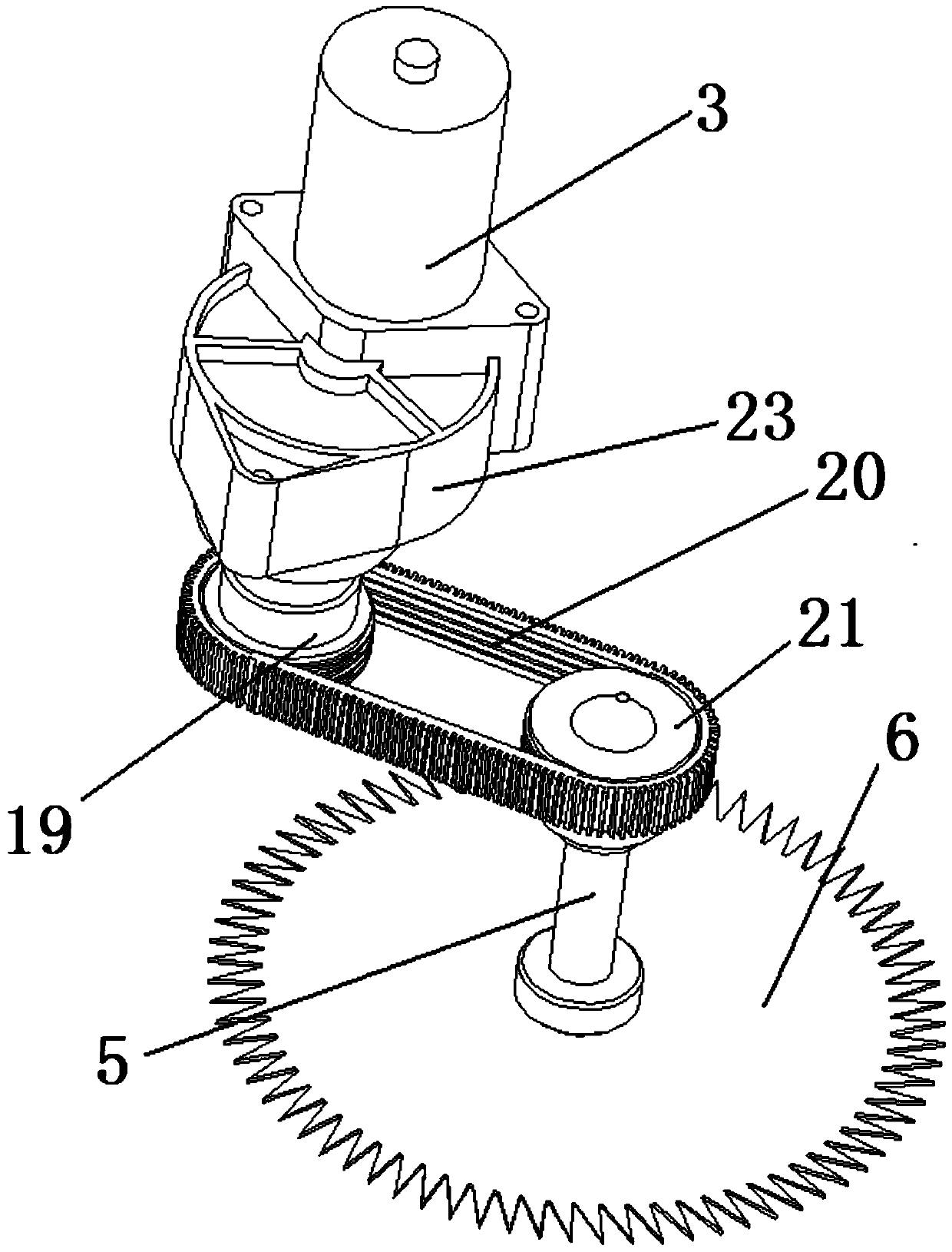

[0028] The first rotating shaft 5 is installed on the front end of the tool rest 2 through a bearing, and the cutter head 6 is fixed on one end of the first rotating shaft 5, and the other end of the first rotating shaft 5 is connected with the output shaft of the motor 3 through a transmission mechanism, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com