Dual-stirrer intensive mixing machine for powder

A double stirring and strong mixing machine technology, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of inability to mix evenly, inability to roll the mixture, and low mixing efficiency, so as to achieve convenient operation for workers Save trouble, improve sealing performance, and improve the effect of using efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

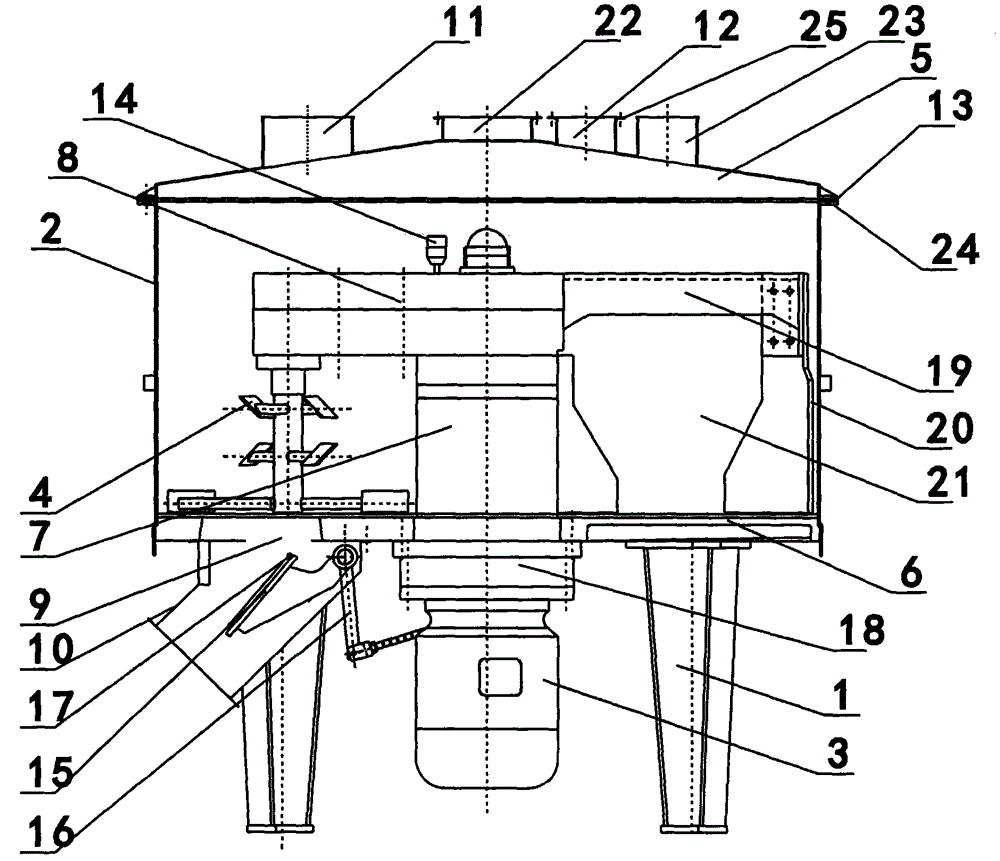

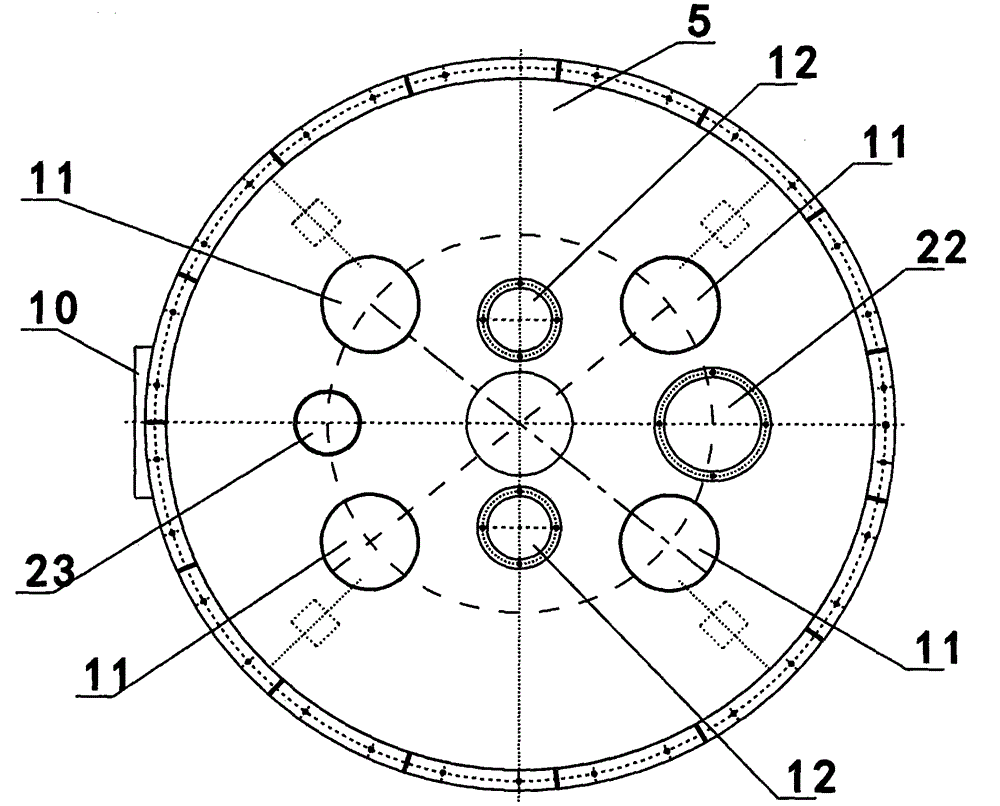

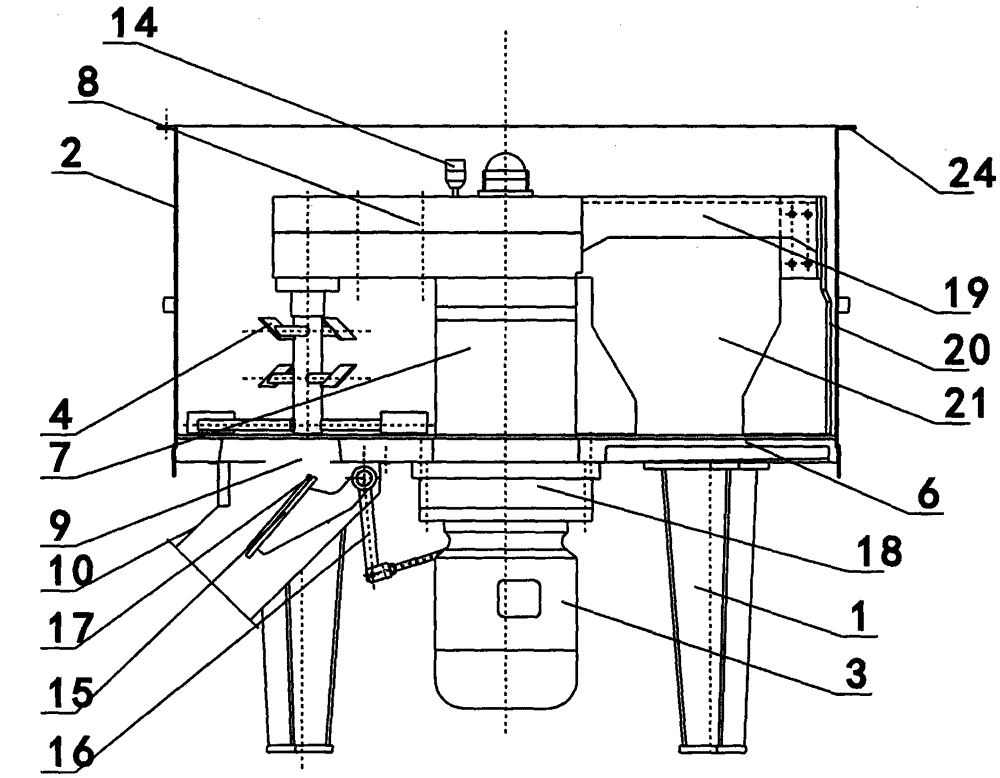

[0026] As an embodiment of the powder double-stirred mixer of the present invention, such as figure 1 , figure 2 , image 3 and Figure 4 Shown, comprise frame 1, material cylinder 2, motor 3, two stirrers 4 and loam cake 5, described material cylinder 2 below is provided with machine disc 6, is arranged on frame 1 by machine disc 6, and described motor 3 is arranged below the machine disk 6, the output end of the motor 3 is provided with a pivot body 7, the motor 3 drives the pivot body 7 to rotate, and the upper end of the pivot body 7 is provided with a rotary arm 8, the rotary arm 8 An agitator 4 is arranged downwards at both ends, a discharge port 9 is provided on the machine plate 6, a discharge cylinder 10 is provided around the discharge port 9, and a feeding tube 10 is provided on the upper cover 5. mouth 11 and two filling holes 12, the upper cover 5 covers the opening at the upper end of the barrel 2, a sealing ring 13 is provided between the upper cover 5 and t...

Embodiment 2

[0038] As an embodiment of the powder double-stirring intensive mixer of the present invention, the difference from Embodiment 1 is that in this embodiment, the angle α between the outer scraper 20 and the scraper arm 19 is 30°; The angle β between the inner scraper 21 and the scraper arm 19 is 45°.

[0039] In this embodiment, other structures and beneficial effects are consistent with those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0041] As an embodiment of the powder double-stirring intensive mixer of the present invention, the difference from Embodiment 1 is that the angle α between the outer scraper 20 and the scraper arm 19 in this embodiment is 45°; The angle β=60° between the inner scraper 21 and the scraper arm 19 .

[0042] In this embodiment, other structures and beneficial effects are consistent with those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com