Tyre clamping device

A technology for tires and clips, which is applied in the direction of lifting devices, etc., can solve the problems of increased manufacturing costs, easy damage to the inner surface of tires, and large occupied area, so as to achieve the effects of improving efficiency, quick pick and place, and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

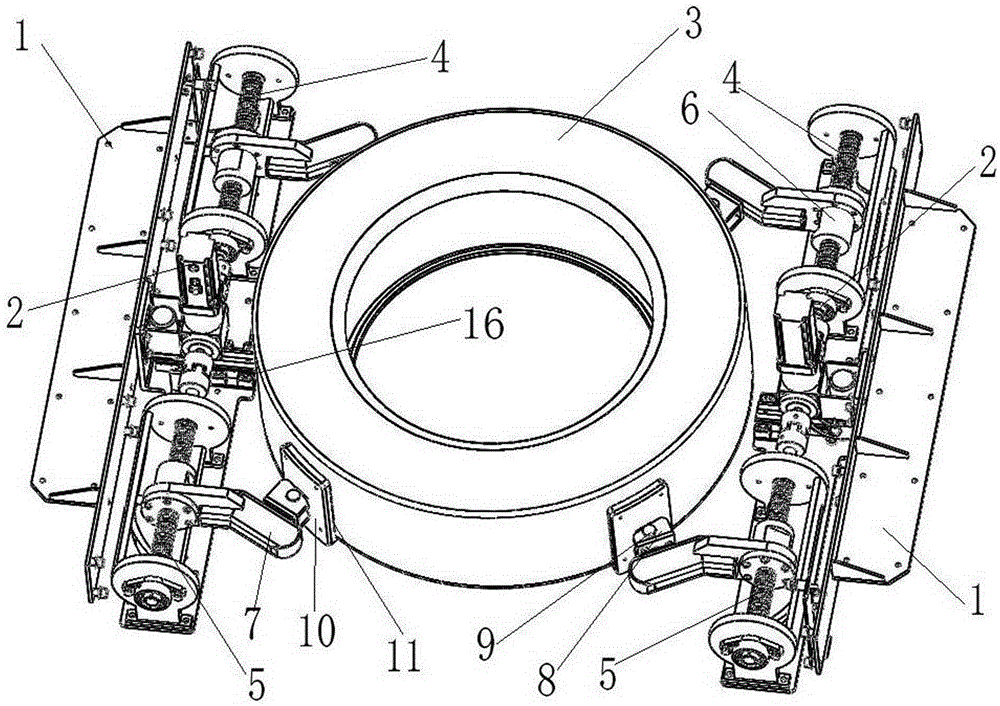

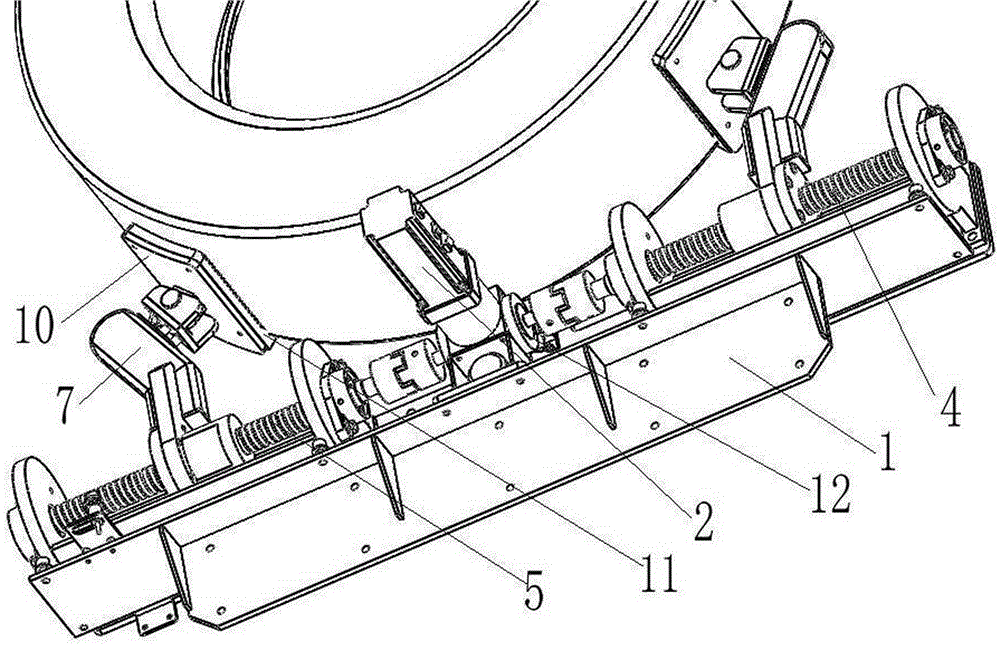

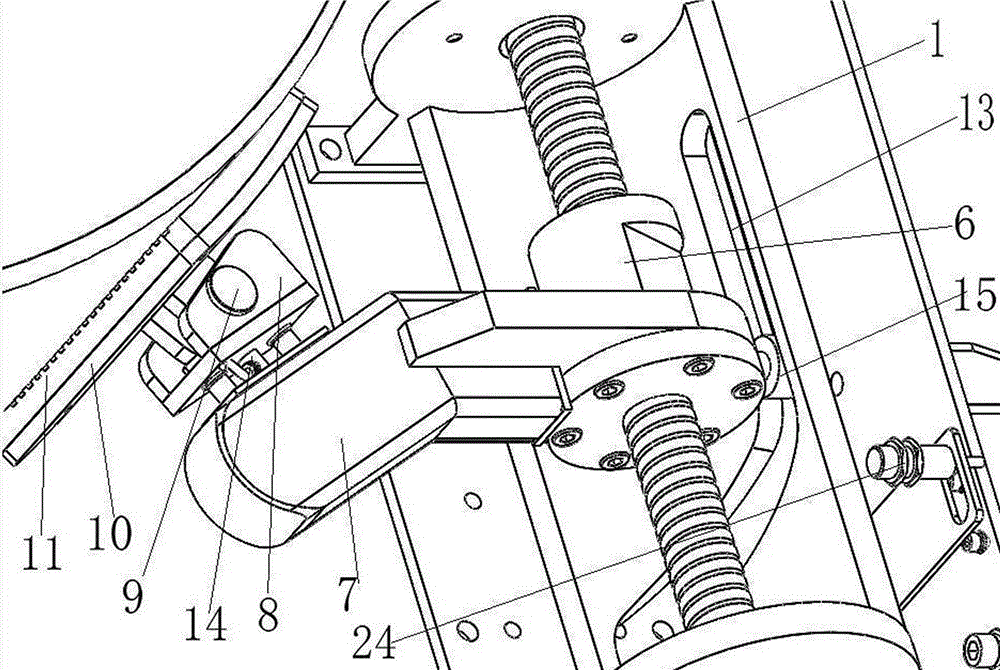

[0026] Attached below figure 1 to attach Figure 6 The present invention will be further described.

[0027] as attached figure 1 As shown, a tire clamping device includes: two bases 1, which are installed parallel to each other on the fork of a stacker or a shuttle, and each base 1 is equipped with two symmetrical clamping arms 7 along the length direction The clamp arm driving device is arranged on the base 1, and is used to drive the two clamp arms 7 on each base 1 to move synchronously and relatively in the opposite direction along the horizontal direction. When the clamp arm driving device drives the clamp arm 7 to move to the innermost end , the space between the four clamp arms 7 is less than the outer diameter of the tire 3, when the clamp arm driving device drives the clamp arm 7 to move to the outermost end, the space between the four clamp arms 7 is greater than the outer diameter of the tire 3; and The clamp arm guiding mechanism is arranged on the base 1, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com