Bulb with heat dissipating system

A technology of heat dissipation system and light bulb, which is applied in heat dissipation design, lighting and heating equipment, cooling/heating device of lighting device, etc., can solve problems such as bulb damage and filament breakage, and achieve the effect of improving versatility, production and processing convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

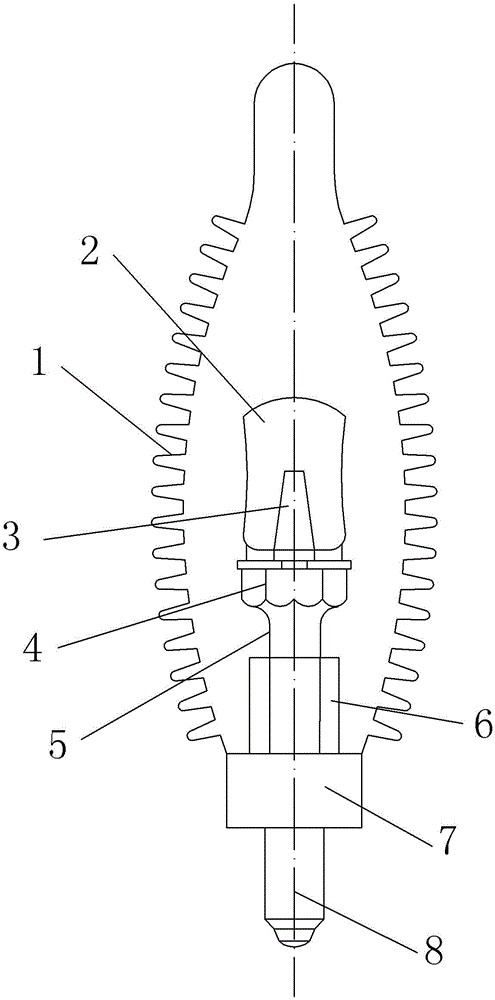

[0012] The reference signs in the drawings of the description include: outer glass bulb 1, inner glass bulb 2, filament 3, filament holder 4, connecting wire 5, stem 6, lamp holder 7, lamp holder 8.

[0013] The embodiment is basically as attached figure 1 Shown: a light bulb with a heat dissipation system, including an outer glass bulb 1. The outer glass bulb 1 has a structure with small ends and a large middle. The uppermost position of the outer glass bulb 1 is an arc-shaped structure. The left and right sides of the glass bubble 1 are respectively provided with rakai heat dissipation ribs. The heat dissipation ribs have a tapered structure with one side large and the other side small. The side where the heat dissipation ribs meet the outer glass bubble 1 is larger, and the There is an arc chamfer at the junction of the heat dissipation rib and the outer glass bulb 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com